Pharmaceutical drug manufacturing and biotechnology processing

Drug development and manufacturing is highly regulated to ensure safety, efficacy, and quality. An important initiative to boost innovation and support efficiency is the Process Analytical Technology (PAT) by the FDA. It is a framework for innovative pharmaceutical development, manufacturing, and quality assurance. PAT encourages using the latest scientific advantages and technology in pharmaceutical manufacturing as well as continuous, real-time quality assurance during processing. Continuous manufacturing (CM) is the new industry trend with many identified benefits over traditional batch-based manufacturing. Successfully implementing PAT or CM requires real-time sensors and measurement equipment.

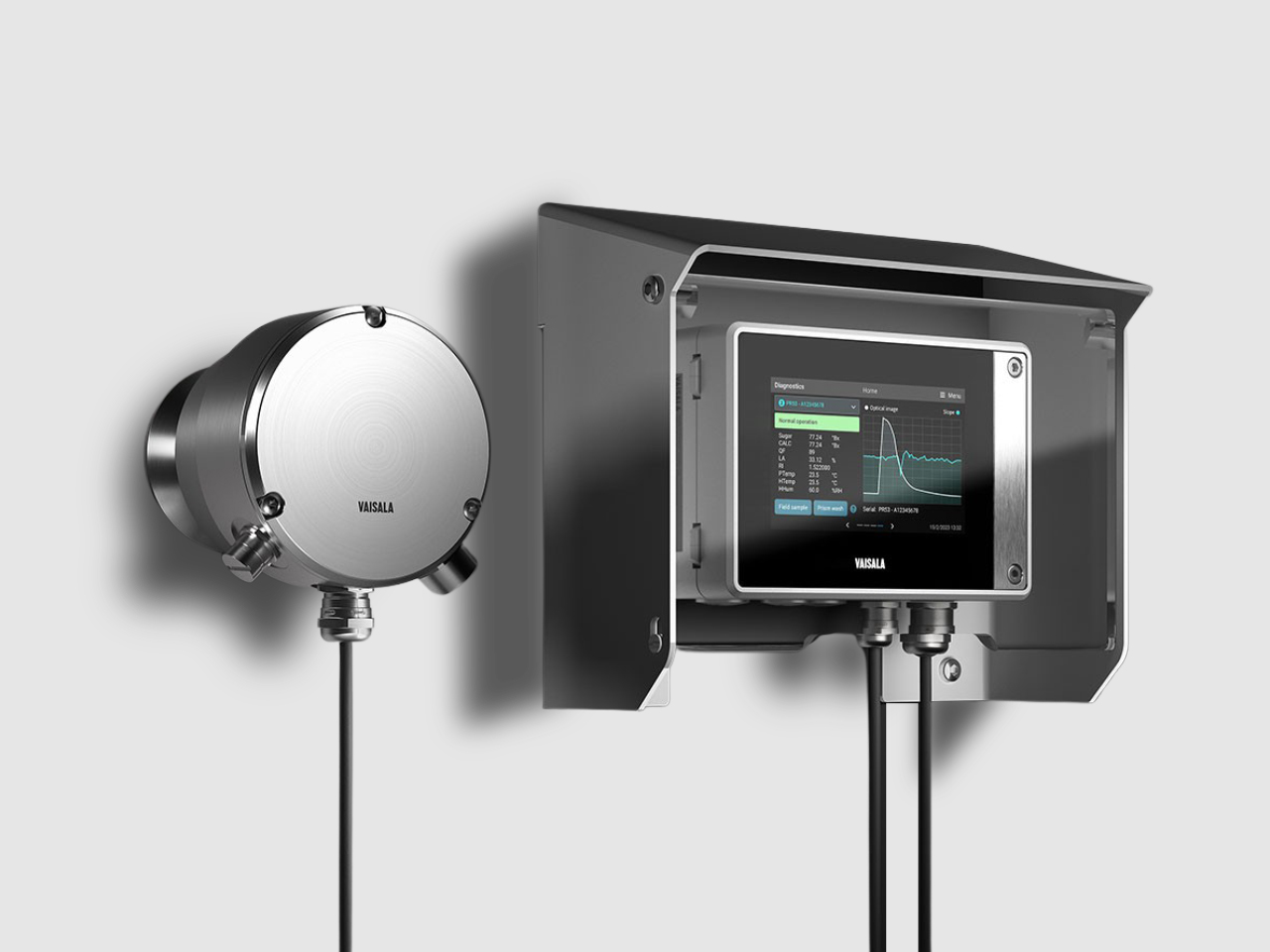

Vaisala Polaris Process Refractometer is suitable for pharmaceutical and biotechnology processes offering reliable, continuous inline concentration measurements for a wide range of applications, such as Active Pharmaceutical Ingredients (API), vitamins, herbal-based medicine, vaccines, penicillin as well as medical protective wear, wound dressings, and medical implants manufacturing.

Quality, safety and efficacy by design

The reliable measurement and data provided by the Vaisala Polaris process refractometer help to understand critical process parameters (CPP), process conditions, and elevate process understanding and fully supports continuous manufacturing. Importantly, this refractometer can help to meet the regulatory requirements for validating, quality, and controlling the manufacturing processes.

In addition, continuous in-line measurements, and provided data help to reduce production cycle times, increase production capability, prevent rejects, abolish human errors in manufacturing and provide high quality and safe products with minimum variability. In drug manufacturing, this technological innovation can be used from laboratory-scale to pilot batches that are used in process development to the production-scale batches needed to support commercialization. In the R&D phase, using the Vaisala Polaris process refractometer can reduce drug development time.

Continuous and accurate inline measurements

Vaisala Polaris process refractometers provide continuous and accurate, reliable, repeatable, and reproducible measurements for applications aligned with Process Analytical Technology (PAT) manufacturing methods.

- Real-time process data via Ethernet – Enables monitoring data for each batch or lot.

- Supports cGMP compliance – Helps ensure manufacturing meets Current Good Manufacturing Practice standards.

- Traceable calibration and verification – Ensures measurement accuracy and regulatory audit readiness.

- Certified for hygienic applications – Meets Sanitary 3-A and EHEDG (European Hygienic Engineering & Design Group) standards.

- It comes with Ex-certified product versions for hazardous areas.

Applications in pharmaceuticals manufacturing

Production of Active Pharmaceutical Ingredients (API)

Real-time concentration measurements during reaction, crystallization, separation and purification, filter cake washing, solvent swap and solvent exchange for the development and production of APIs.

Solvent swap or solvent exchange

Monitor your solvent swap operation during API production by measuring the concentrations of the original and swap solvents.

Pharmaceutical crystallization

Determine exact seeding point and yield only high-quality crystals during API production.

Filter cake washing

Acquire deep process understanding by measurement data, develop unique washing profiles and find the most suitable washing solvent for increased yield and maximum wash result.

Aspirin crystallization

Measure liquid phase in aspirin (acetylsalicylic acid) crystallization and control your crystallization process

Pharmaceutical extraction: herbal-based medicine

Always achieve your target extract concentration during solid-liquid extraction (leaching).

Applications in biotechnology processes

Timely measurements for the development and monitoring of biopharmaceuticals processing such as fermentation, cell culture, protein buffer solutions and concentration. Download our application notes for more information.

Pharmaceutical fermentation

Measurement solutions for standardizing and automating processes. From fermentation profile design to scale-up and for determining the endpoint of fermentation instantly and reliably with no deviations on full-scale production.

Vaccines production

Collect only the virus fraction with correct density for best yield in purification operations/downstream processes.

Protein concentration and filtration

Control retentate concentration for good permeability even with the smallest of particles.

Penicillin production

Measure concentration of raw penicillin, monitor fermentation process and maintain optimal conditions with high yield during penicillin production.

L-Lysine evaporation process

Control your evaporation process with an industrial process refractometer.

Blood plasma intermediate ultrafiltration

Measure protein concentration safely inline and real-time, control retentate concentration precisely for optimal permeability

Related articles

Enhancing antibody production with inline process refractometers

See how inline process refractometers enable continuous, drift-free concentration measurement in antibody production—from feed preparation and buffer make-up to protein concentration and final fill.

Blood plasma intermediate ultrafiltration

Learn how inline refractometers improve plasma ultrafiltration processes with recommended installation points for best performance.

Medical applications

Wound dressing, medical implants manufacturing and medical protective wear. Download our application notes for more information. Download our application notes for more information.

Alginate wound dressings and fabrics

Monitor alginate dope solution and coagulation bath concentrations in wet-spinning for operations for best fiber quality.

Medical implants and device surface treatments

Monitor and control acid (for example nitric acid HNO3) during medical parts passivation to meet product specifications.

Dipping baths in rubber and medical gloves manufacturing

Ensure protective clothing's critical final quality and durability by measuring Total Dissolved Solids (TDS) in liquid latex, nitrile, vinyl or synthetic polyisoprene dipping baths.

Maximum productivity and safety in hazardous areas

The industry-leading Vaisala Polaris process refractometers offer Ex-certified product versions for hazardous areas.

Depending on selected product option, the refractometers are designed to be installed in either

IECEx/ATEX Zone 0/1 (North America Class 1 Division 1) or Zone 2 (Class 1 Div 2).

The Polaris Ex-versions are Indigo520 compatible to secure maximum productivity.

The Indigo520, and the associated IS equipment in case of Zone 0/Class 1 Div 1, is placed in the safe area.

Pharmaceutical drug manufacturing and biotechnology processing related products

Vaisala Polaris™ PR53AC and ACEX Sanitary Compact Process Refractometers for ordinary and explosive areas

Vaisala Polaris™ PR53AP and APEX Sanitary Probe Process Refractometers for ordinary and explosive areas

Indigo520 for process refractometers

Can't find your application?

Only some examples of our refractometer applications are listed here. There are still hundreds more!

Our application experts will help you. Tell us a bit more by filling the form or contact us.

Liquid concentration measurement

Vaisala offers a wide range of products tailored to liquid measuring needs of different industries.

Learn more about the refractometer technology and its applications, and visit the library of product related assets.