Vaisala DRYCAP® Technology

As the leading developer and provider of humidity measurement instruments, Vaisala knows also the very dry measurement conditions.

Reliable data needed

The demand for reliable moisture measurement instruments grew in the 90s, and it was noticed that the traditional humidity probes were not accurate enough at very low humidity levels. The commonly used aluminum oxide sensors were prone to drift and required frequent calibration. A new type of a moisture sensor was needed.

Taking every measure for the planet

We took on the challenge by combining the highest quality polymer technology with a patented key feature – auto-calibration – that would eliminate sensor drift in very dry conditions.

The era of DRYCAP® begins

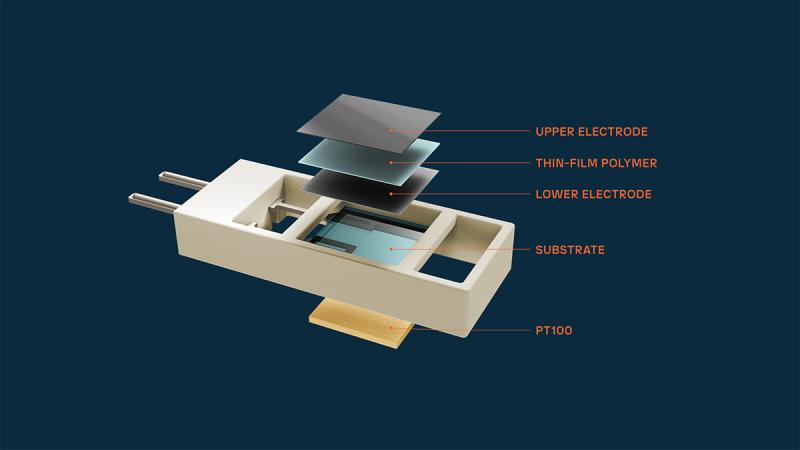

In 1997, we introduced a new type of dew point sensor based on thin-film polymer technology, the DRYCAP® sensor, that could be used in various Vaisala probes for dry measurement conditions.

The parameter of high demand

Since its launch, the DRYCAP product family has grown to encompass a huge range of applications, from drying processes to compressed air and dry chambers. The DRYCAP sensor is particularly renowned for its reliable performance in hot and very dry environments and this highly successful innovation is continuously growing its demand.

When process measurement truly matters

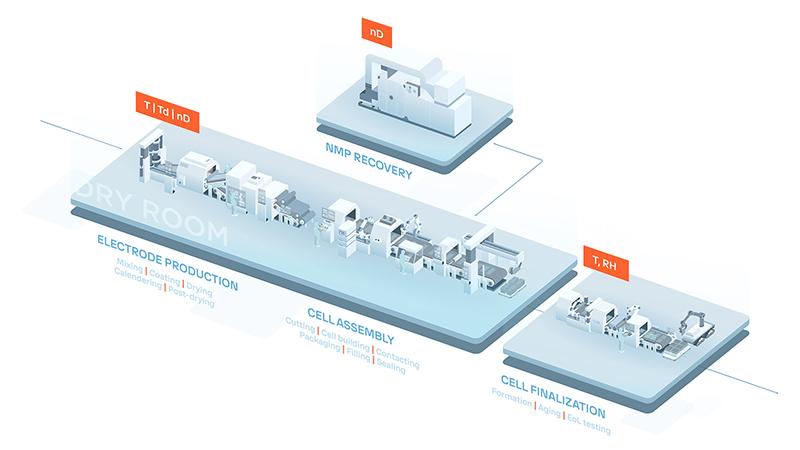

An example of the several demanding industrial applications where Vaisala DRYCAP technology is used today is battery manufacturing. Due to the ultra-low humidity requirement and highly controlled atmospheric conditions, reliable dew point measurement is a must. The accurate and stable data the instruments provide, enable controlling the moisture levels along any critical locations of the process, such as the electrode production.

How Vaisala DRYCAP works

DRYCAP’s unrivalled performance is based on two innovations: the proven capacitive thin-film polymer sensor and the auto-calibration function. The sensor’s thin-film polymer absorbs or releases water vapor as the surrounding humidity increases or decreases. The dielectric properties of the polymer change as the humidity around the sensor changes, as does the capacitance of the sensor. Capacitance is converted into a humidity reading. The capacitive polymer sensor is bonded together with a temperature sensor, and dew point is calculated from the humidity and temperature readings.

Auto-calibration

Vaisala’s patented auto-calibration function optimizes the measurement stability in dry environments. The sensor is heated at regular intervals during the automated auto-calibration procedure. The humidity and temperature readings are monitored as the sensor cools to ambient temperature, with offset correction compensating for any potential drift. This enables the DRYCAP sensor to deliver accurate measurements in the long term, dramatically reducing the need for maintenance.

Sensor purge

Sensor purge is also an automatic procedure that minimizes the drift at the wet end readings of the dew point measurement. Sensor purge is performed regularly and when the power is switched on. The sensor is heated for several minutes, which will then evaporate all excess molecules out of the sensor polymer. This, together with the auto-calibration, results in a very small drift. The measurement output of the transmitter is frozen to the last measured value for the duration of the sensor purge.

Key benefits and features of Vaisala DRYCAP technology

High chemical tolerance

Immune to contamination by compressor oils and volatile organics

Withstands saturation

Tolerates condensing environments and getting wet

Fast response time

From dry to wet 5 seconds (15 s) & from wet to dry 45 seconds (8 min)

Sensor purge and warming

Improved measurement accuracy and less frequent calibration needs

Excellent accuracy and stability

Reliable measurement with very small hysteresis

Vaisala quality

DRYCAP is constantly developed by our scientists and manufactured in our high-quality cleanrooms

DRYCAP® application examples

Below you can see some applications, where the DRYCAP technology and our related dew point measurement instruments play a key role among other measurement parameters. Instruments with Vaisala DRYCAP sensors are often used is conditions under 10%RH (relative humidity), where as our HUMICAP technology covers ambient and high-humidity measurement conditions. Please contact our sales engineers if you have questions or concerns about your measurement instrument needs.

Battery manufacturing

Critical moisture and liquid concentration measurements

Ensure safe operations and quality end-products with the help of reliable measurements

Semiconductor

Prevent spoilage and failure due to humidity

Utilize precise data on the manufacturing environment

Compressed air

Save energy and improve product quality through moisture control

Measuring small changes in dew point temperature can add to immeasurable results in compressed air quality

Metal heat treatment furnaces

Successful metal heat treatment requires dew point measurement

The moisture content in the furnace atmosphere affects the quality of the heat treatment process

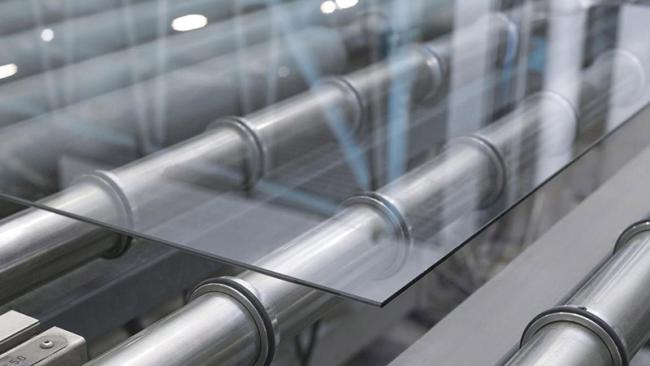

Glass manufacturing

Glass manufacturing quality through moisture control

Measure dew point in blanketing atmosphere with Vaisala DRYCAP® sensor technology

Plastics drying

Ensuring the optimal dryness of plastic pellets

When manufacturing injection molded plastic products, correct drying of the raw material is crucial

Veneer drying

Veneer quality through dew point control

Bringing out the beauty of wood for the most demanding needs requires moisture data

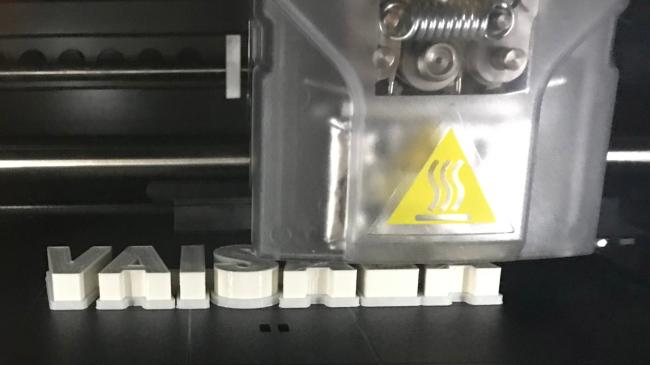

Additive manufacturing

Savings in time, money, and materials

High moisture levels within the raw material can change its chemical properties and may negatively affect final product quality.

Products using DRYCAP® Technology

Dew Point Probe DMP1

Dew Point and Temperature Probe DMP5

Dew Point Probe DMP6

Dew Point and Temperature Probe DMP7

Dew Point and Temperature Probe DMP8

Indigo500 Series Transmitters

Indigo80 handheld measurement device

DMP80 DRYCAP® Handheld Dew Point and Temperature Probes

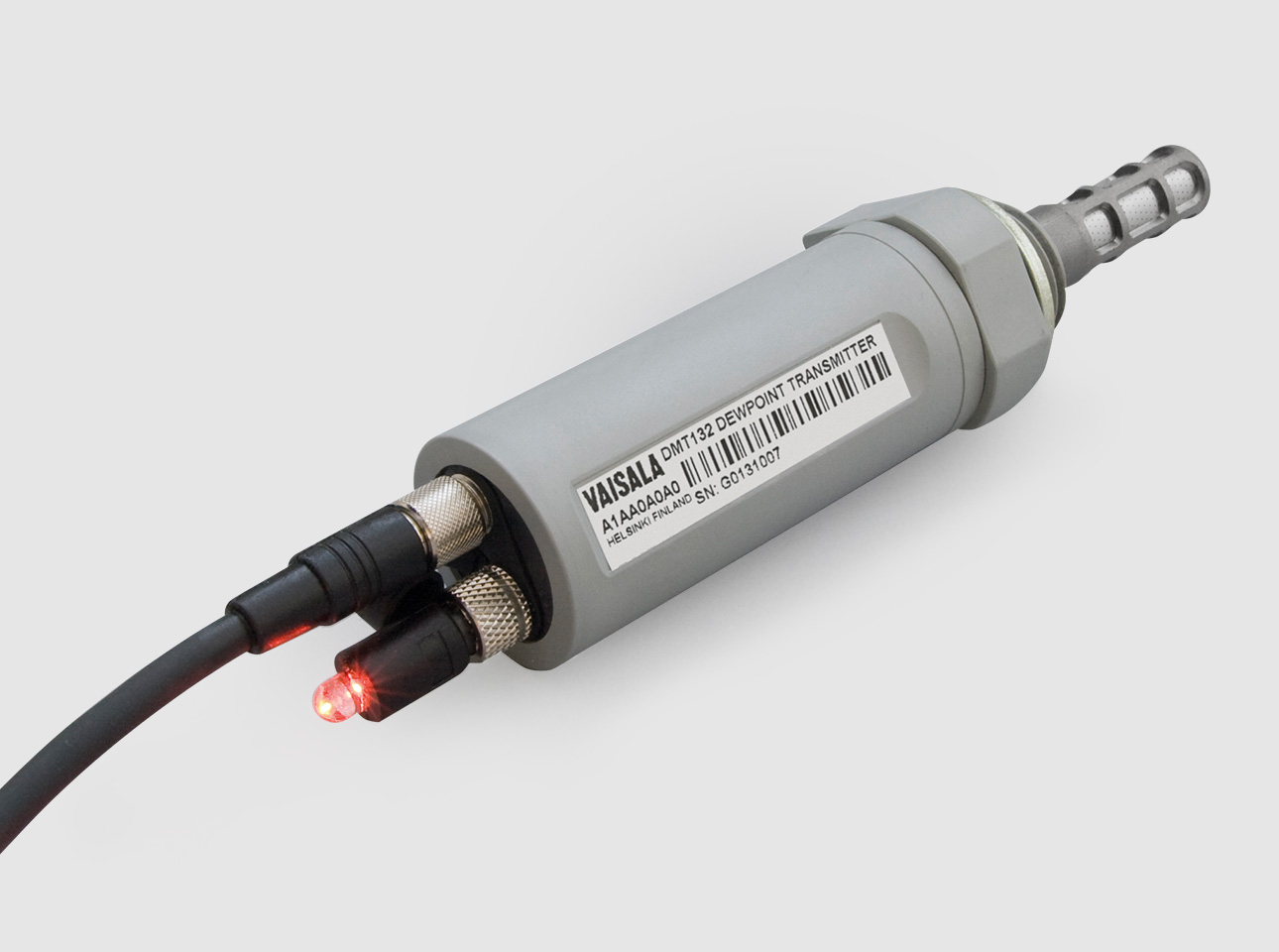

Dew Point Meter DMT132

Dew Point Transmitter DMT152

Miniature Dew Point Transmitters DMT143 & DMT143L (Long)

Dew Point and Pressure Transmitter DPT146

Quick dew point calculations and conversions with Vaisala Humidity Calculator

Calculations related to dew point and frost point temperature can sometimes be tricky. Vaisala Humidity Calculator app is your daily help with several types of humidity and moisture related calculations and unit conversions. You can use it in a browser or download it to your phone.

Dew point or frost point temperature?

Dew point temperature is used to describe the temperature at which moisture in the air will begin to condense as dew. Frost point temperature describes the temperature at which moisture in the air will begin to condense as frost or ice.

See our recommendations regarding dew point and frost point temperature measurement outputs in low humidity applications.