Vaisala HUMICAP® Technology

Today, Vaisala is a leading provider of humidity measurement probes to multiple industries and in many applications. Relative humidity sensors are now an industry standard. Here is how it started.

We need to fix this

Up until the early 1970s, hair hygrometers were widely used despite the unreliable humidity measurements they provided. To address this, Vaisala embarked on the development of a novel humidity sensor employing semiconductors and thin-film materials.

HUMICAP® is born

At the CIMO VI congress in 1973, Vaisala introduced the HUMICAP®, the world's first thin-film capacitive humidity sensor. This groundbreaking innovation revolutionized humidity measurements. The HUMICAP sensor had no moving parts and thanks to the advanced utilization of semiconductor and thin-film technologies, it was amazingly small in size.

From one company’s invention to a global standard

Since then, Vaisala has emerged as the market leader in relative humidity measurements, and thin-film capacitive humidity sensors have transcended being one company's invention to a global industry standard.

Constantly evolving

HUMICAP is not only a sensor, it is a solution to many challenging measurement positions and conditions. HUMICAP is in Vaisala's core and we develop it constantly.

If it works on Mars, it works anywhere

The unforgiving conditions in space pose strict demands on technology, requiring the most reliable sensors that can be trusted to endure without repair. You simply cannot venture out into these conditions with just any instrumentation. Therefore, the HUMICAP products were a natural selection to measure conditions in the planet MARS since 1990s.

HUMICAP in numbers

launched

of measurements based on HUMICAP

planets

HUMICAP - The tiny giant

Humidity is everywhere. It affects our comfort, health, and productivity. It also influences the quality and safety of many products and processes. That’s why measuring and controlling humidity is essential in many industries and applications.

HUMICAP is not only a sensor, it is a solution.

Watch the introductory video of the tiny giant.

How it works

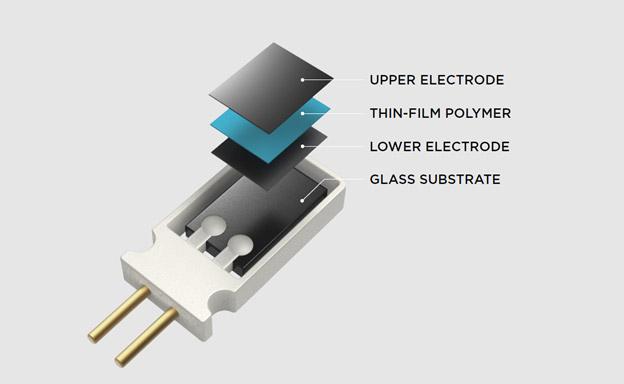

HUMICAP is a capacitive thin-film polymer sensor consisting of a substrate on which a thin film of polymer is deposited between two conductive electrodes.

The electrode facing ambient air is made of porous metal to protect the sensor from contamination and exposure to condensation. The substrate is typically glass or ceramic. The thin-film polymer either absorbs or releases water vapor as the relative humidity of the ambient air rises or falls.

The dielectric properties of the polymer film depend on the amount of absorbed water. As the relative humidity around the sensor changes, the dielectric properties of the polymer film change, and so does the capacitance of the sensor. The instrument’s electronics measure the capacitance of the sensor and convert it into a humidity reading.

Customer testimonials

"When you find products – and a company – you can trust,

...it makes good business sense to continue the relationship. Futamura have been using Vaisala measurement instruments for many years to help us ensure the quality of our sustainable packaging films, and we will continue to do so in future. As a plant we like to keep a site standard as it makes it easier to keep spares and to replace equipment when necessary. It’s safe to say that Vaisala is our brand of choice because of its reliability and ease of installation and use."

David Carr, Electrical Engineering Chargehand, Futamura UK

"The Vasa Museum wanted accurate and reliable measurement instruments.

Therefore, Vaisala was an obvious choice based on our previous experience."

Fred Sörensen, Project Manager, TAC Sweden

“At Viking Malt we work very hard to ensure the production of consistent, high quality malts.

This is achieved through the careful selection and management of raw materials and by monitoring and controlling production as carefully and precisely as possible."

Tony Öblom, Technical Manager, Viking Malt Sweden

Condensation prevention technology with warmed probe

One of Vaisala's innovations in the humidity measurement field includes warmed probe technology for the toughest high humidity environments. Saturation in the environment causes condensation to form on all surfaces including measurement sensors, which can be fatal for some technologies. A warmed probe keeps the sensor continuously above the ambient temperature, ensuring condensation never forms. With Vaisala's solution, relative humidity measurement is possible in these conditions with an additional Indigo520 transmitter.

In the visualization, the Vaisala HUMICAP® probe A has a heating functionality, whereas the probe B is non-heated. When 100% relative humidity (RH) is reached, probe A recovers quickly to show accurate humidity readings whereas B recovers very slowly. Depending on the device, recovery can take hours.

Unique benefits

Excellent long-term stability and repeatability

The sensor is so linear that it is enough to have only 2 adjustment points, reducing the amount of work in calibration.

Insensitive to dust and most chemicals

And for the toughest environments with high concentrations of chemicals, Vaisala offers chemical purge option

Fast response time

fast response improves process control in rapidly changing conditions

Sensor heating

Sensor heating for measurements even in condensing environments

Full recovery from condensation

Measurement is accurate immediately after condensation has evaporated.

The most reliable and accurate humidity measurement

even in the harshest environments

HUMICAP® applications by industry

Even though the HUMICAP innovation was originally designed for a new type of a radiosonde, the word got around about reliable humidity measurements, and created a growing demand in many industries and applications. Today we offer everything you need for measuring humidity, with a wide range of humidity instruments covering applications from HVAC to the most demanding industrial applications, both indoors and outdoors.

Automotive

Accurate humidity, dew point, and concentration control for the best product quality for the automotive industry

Improve automotive processes from design to storage in various applications, and ensure product quality

Aviation

Ensure safe and efficient airport operations in all conditions

Continuous humidity measurements help airports detect upcoming storms to ensure safe and efficient takeoffs and arrivals in any weather

Battery manufacturing

Critical moisture and liquid concentration measurements

Ensure safe operations and quality end-products with the help of reliable measurements

Building Automation

Measure humidity and CO2 in all critical spots to optimize your HVAC system

Gain better energy efficiency, indoor air quality and optimal system operation with room, duct and outdoor installations for precise humidity and CO2 monitoring

Chemical

Secure efficient and safe chemicals drying, processing, and storage

Measure relative humidity, absolute humidity, and temperature for best quality products and safe operating conditions

Data Centers

High-accuracy measurement solutions for data centers and mission-critical facilities

Improve energy efficiency by high-precision humidity and temperature measurements with minimum maintenance needs.

Defense Meteorology

Understand the impact of weather on operations and personnel safety

Humidity measurements play a key role in situational awareness for planning operations and training exercises and keeping personnel safe

Food, beverage and agriculture

Accurately monitor and control humidity in food manufacturing, transportation, and storage.

Secure products' shelf-life, freshness, taste, and safety for consumption

Fuel cells & electrolyzers

Improve fuel cell and electrolyzer testing and manufacturing

Choosing the right humidity measurement technology can save you hours and take your processes to a new level

Life Science

Keep your cleanrooms running smoothly and incubators always within specifications

Measure, monitor, and record humidity real-time

Maritime

Ensure safe and smooth maritime operations

Reliable marine humidity observations keep crew members safe and sound and maritime operations running smoothly

Meteorology

Ensure a better and safer daily life

The long-term stability of HUMICAP® ensures high-quality data for global synoptic and climatological observations. Used both in upper air radiosondes and surface weather observations, precise humidity data enables accurate weather forecasting and precipitation prediction

Power

Extend your power transformer's operational life. Avoid free water formation and decreased breakdown voltage of insulating liquids.

Our robust moisture in oil probes have become the virtual industry standard for condition monitoring of power transformers. Compatible with mineral oil, natural & synthetic esters, and silicon liquids

Pulp, paper and wood

Reverse the effects of humidity in a paper mill with accurate humidity measurements

Avoid excess humidity in the hood with proper moisture control and achieve the desired paper quality and consistency

Roads

Empower your winter road maintenance and management decision-making

Accurate dew point measurements help to predict frost and black ice formation on the road surface — critical for ensuring road safety

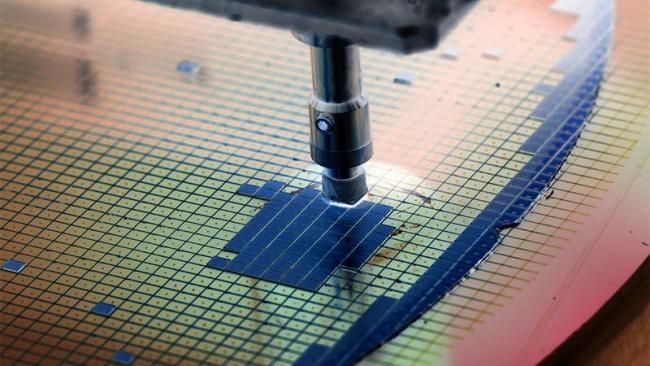

Semiconductor

Prevent spoilage and failure due to humidity

Utilize precise data on the manufacturing environment

Urban resilience

Help communities gain a deeper connection to their environment

Accurate humidity measurements provide a clearer picture of current environmental conditions in cities and industrial areas

Product documentation

More downloads

Examples of HUMICAP® products

Indigo Family - the modular platform

HUMICAP® Humidity and Temperature Probe HMP155

Humidity and Temperature Probe HMP110