Fuel cell efficiency through humidity intelligence

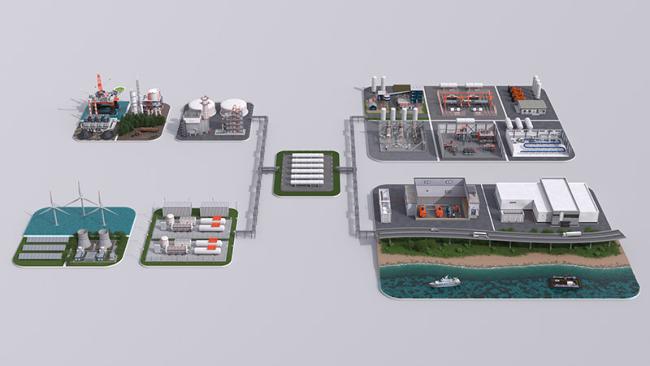

Energizing the hydrogen economy

Advancing the hydrogen economy has a significant impact on reducing our carbon footprint. Fuel cells have a special role to play in this future vision, but they depend on reliable humidity data. The concise 3-minute video will cover some future insights about the hydrogen economy and the use of fuel cells. You will also see how humidity data is related to fuel cell quality.

Next, get immediate access to presentation "Fuel cell R&D – Future trends, drivers and applications" for further insights from our Senior Strategy & Business Development Manager Anu Pulkkinen.

Vaisala is a leading provider of humidity measurements in PEM fuel cell testing. Our sensors use our proprietary HUMICAP technology, ensuring reliable data even in the most challenging measurement conditions. Warmed-probe technology is our innovation for high-humidity environments. The heating function keeps the sensor continuously above the ambient temperature, ensuring condensation never forms. This minimizes the recovery time between measurements and increases the efficiency of fuel cell testing.

Fuel cell testing doesn't have to test your patience

An efficient PEM fuel cell testing process can save you hours. That is possible when you don't have to wait for your humidity instrument to recover from condensation. The recovery time depends on the technology and stability of the probe.

In the visualization, the Vaisala HUMICAP® probe A has a heating functionality, whereas the probe B is non-heated. When 100% relative humidity (RH) is reached, probe A recovers quickly to show accurate humidity readings whereas B recovers very slowly.

Fuel Cell Humidity Lab

Are you curious about the impact of humidity measurement on the outcome of PEM fuel cell testing? Get free access to our Fuel Cell Humidity Lab webinar sessions hosted by our Product Manager Juhani Lehto!

Each session is under 30 minutes, so you can use your time efficiently by getting just the key facts. Learn more about each session below and register to ensure your virtual seat.

Humidity measurement basics for the fuel cell industry

Selecting a humidity measurement instrument for fuel cell testing

Taking a fuel cell humidity measurement instrument into use

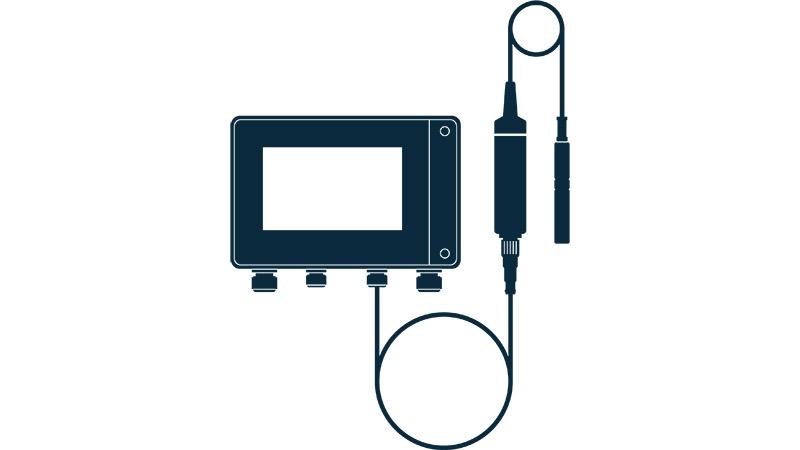

Compact and compatible. Vaisala HUMICAP® HMP7 for high humidity conditions.

Vaisala HUMICAP® HMP7 measurement probe thrives in applications which involve constant high humidity or rapid changes in humidity such as humidifiers, drying and test chambers, combustion air and measurements where performance and chemical tolerance are essential.

Moreover, the HMP7 is compatible with our robust Indigo500, Indigo300 and Indigo200 transmitters, which enable easy data evaluation and visualization.

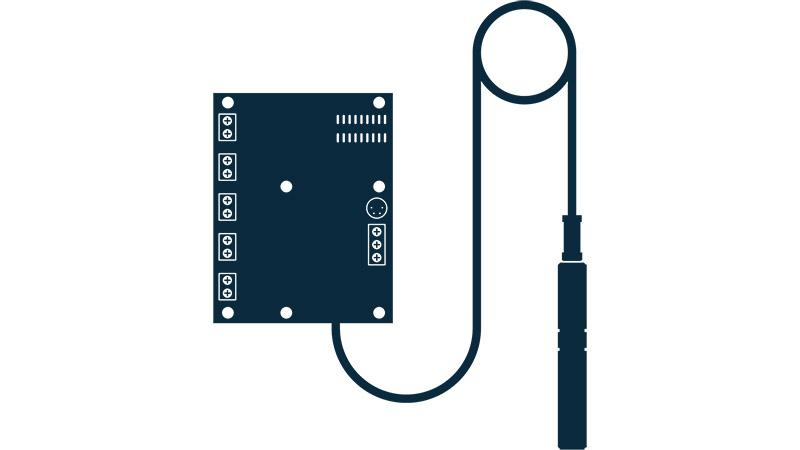

Easy to integrate. Vaisala HUMICAP® Humidity and Temperature Module HMM170 for high humidity conditions.

This robust, open frame transmitter is the ideal choice when you need to integrate the device into fuel cell test equipment or other environmental chamber. The sensor tolerates high humidity, vacuum as well as high pressure conditions.

The integration is easy. Both digital and three configurable analog output channels are available, ensuring compatibility for most chamber types. In addition to relative humidity and temperature, also dew point and other calculated parameters are available. An integrated service port enables quick configurations.

Fuel cell measurement cases, papers & tools

Expert insights on the future of fuel cells

Additional products for fuel cell applications

Indigo500 Series Transmitters

for demanding data transmission needs with WiFi and PoE connectivity

Indigo300 Series Transmitters

for data transmission needs through analog signals

Indigo80 Handheld Indicator

for spot-checking, field sampling, data analysis and diagnostics

Vaisala HUMICAP® HMT370EX for intrinsic safety

Can be used for high temperatures applications by extracting and cooling down the process air.

Vaisala HUMICAP® HMT317 for high humidity conditions

The HMT317 is a small and simple choice from our previous product family.