Compressed air measurement

Measuring small changes in dew point temperature can add to immeasurable results in compressed air quality

Measuring dew point in compressed air pays off

When dealing with compressed air, measuring small changes in dew point temperature can make a big difference. Benefit from our unique DRYCAP® sensor technology that covers the full dew point range for practically any compressed air system. Increasing the life of your compressed air system, improving process quality and lowering costs is now easier than ever.

Whatever your application, you’ll find the optimal dew point instrument from the Vaisala portfolio. All Vaisala sensors withstand exposure to contaminants like water spikes, ambient humidity, compressor oil and chemical impurities.

The difference with Vaisala DRYCAP® sensor technology

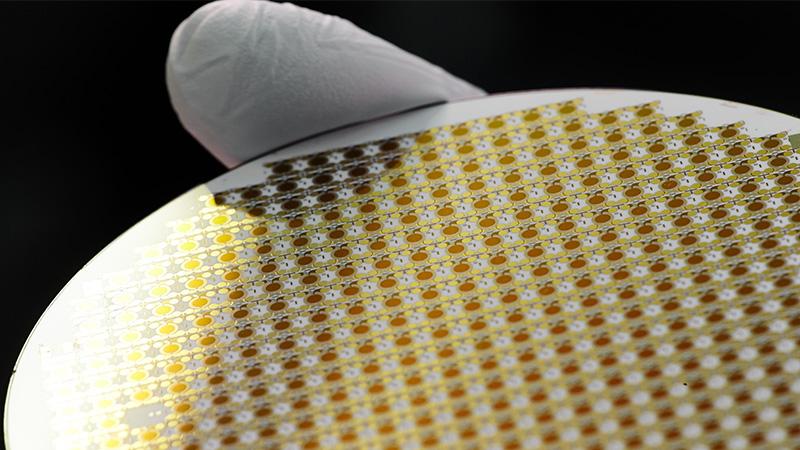

The sensor’s highly sensitive thin-film polymer, manufactured at Vaisala's in-house cleanroom, absorbs or releases water vapor as the surrounding humidity increases or decreases. The dielectric properties of the polymer and the capacitance of the sensor react to humidity changes.

In comparison to conventional dew point instruments, Vaisala DRYCAP® tolerates condensing environments and getting wet, and it is also immune to contamination thanks to the sensor chemical purge functionality. Vaisala DRYCAP provides excellent accuracy and stability with very small hysteresis and a fast response time with minimal drift.

High-quality compressed air lets you focus on what matters

Material savings through quick reaction time

Vaisala's dew point measurement instruments utilize Vaisala DRYCAP technology with some of the fastest wet-to-dry and dry-to-wet response times in the market.

Energy savings through measurement stability

Avoid excess drying and rely on Vaisala's patented auto-calibration function to maintain the measurement stability and keep the production conditions optimized.

Cost savings through accurate measurements

Vaisala's dew point measurement products help you prevent unwanted developments such as corrosion of equipment or growth of bacteria.

Compressed air sampling

Sampling is needed when direct measurement of the air is undesirable or is simply not feasible. This may be due to a high process temperature, the need to protect the sensor from water spikes, the added convenience of installing and removing the instrument from a pressurized process without shutting down the line or wanting to take the measurement in a more convenient location.

To get a representative sample of the process gas and avoid potential sources of error caused by incorrect sampling practices, a few aspects should be considered. Read more or read an application note with our sample cell options.

Manage compressed air moisture

Product Manager Vuokko Lantz shows how easy it is to spot-check the dew point readings of an industrial compressed air system with Vaisala Indigo80 Handheld Indicator. You will also see the installation of DMP80 dew point meter and DSC74 sample cell to the compressed air system and using the datalogging functionality of Indigo80. At the end of the video, Vuokko shows how to manage the logged data with Vaisala Insight PC software.

Why measure dew point in compressed air and pneumatic equipment?

Dew point is one of the most important parameters associated with the quality of compressed air and end-products of pneumatic equipment such as 3D printers. Dew point temperature can be defined as the temperature to which air must be cooled for the water vapor within to condense into dew or frost. At any temperature, there is a maximum amount of water vapor that the air can hold. This maximum amount is called the water vapor saturation pressure. Dew point is pressure dependent whereas relative humidity is temperature dependent.

The key goals for measuring dew point are often to ensure high product quality, optimal human health or that energy and capacity are not being wasted. Read more in our Compressed Air Guide.

Modular dew point, relative humidity and temperature instruments as well as wall transmitters for continuous measurement or spot-checking of compressed air process lines and pneumatic equipment

Indigo300 Series Transmitters

Indigo80 Handheld Indicator

for spot-checking, field sampling, data analysis and diagnostics

DMP7 Dewpoint & Temperature Probe

DMP8 Dewpoint & Temperature Probe

DMP80 DRYCAP® handheld probe for dew point and temperature

Compact dew point probes for manufacturers of compressed air dryers, plastics dryers and other pneumatic equipment

DMT132 Dewpoint Transmitter

Miniature DMT143 & DMT143L Dewpoint Transmitters

DPT146 Dewpoint and Pressure Transmitter