Food, beverage and agriculture

A bite of science, a sustainable future

The food and beverage industry is in transformation towards a more sustainable future. For better informed decisions, reliable measurement data is needed.

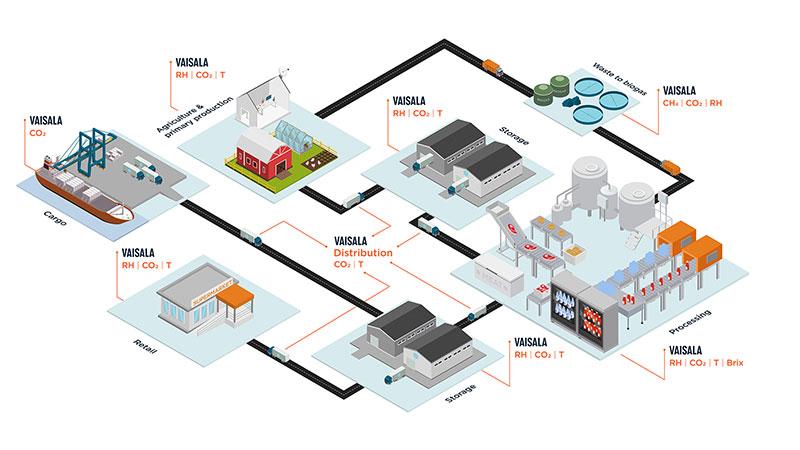

From primary production all the way to your table, Vaisala offers an eye into the unknown.

We provide reliable measurement data for critical parameters impacting the quality, flavor, safety and nutritional value of food & beverages — now and in the future.

(Click the image to enlarge)

Latest in Vaisala food science

Thinking green. The future of food?

The food & beverage industry is facing pressure on all sides. Demands for sustainability, safety and healthiness are complemented by the pressing need to be part of the solution in our climate crisis.

Our expert article covers what tackling the challenges of feeding an increasingly urban and affluent global population entails.

Webcast: The future of food

How will our food be produced? Can food production help alleviate the climate crisis? Will vertical and urban farming change our landscape? Could vat-grown meat make food crises a thing of the past? What will we eat on Mars?

All these and more is covered in an intensively visionary panel discussion. Together with Dr. Lauri Reuter, Ph.D. a visionary biotechnology scientist of Singularity University and Vaisala's Jutta Hakkarainen & Maria Uusimaa, directors of Liquid Measurements and Industrial Instruments, respectively, talk about tackling the megatrend-level challenges facing not just the food & beverage industry, but all of our planet.

Agriculture & primary production

Today's farmers are managers who need to ensure stable conditions for a good yield of high-quality produce and animal welfare.

Monitoring carbon dioxide (CO2), relative humidity, and temperature sets conditions in greenhouses and vertical farming facilities, as well as inside livestock facilities to a new level of primary agricultural production.

Discover our solutions for primary production and agriculture.

Transportation, storage & safety

Shelf-life of produce, its freshness, taste and safety for consumption are greatly defined by the transportation and storage conditions. Accurate monitoring and control of temperature, humidity and carbon dioxide ensure proper preservation of food items, timely ripening of fruits and vegetables and seasonal food variety for consumers in different destinations and working safety for storage and production personnel.

Discover our solutions for storage, transportation and safety.

Food & beverages processing

Here you will find information on how to enable sustainability and efficiency of food and beverages processing.

Measure the critical processing parameters such as in-line Brix and dry solids or total solids in liquid food and beverages processing, humidity and dew point in drying processes, and carbon dioxide (CO2) in production and refrigeration facilities, and ensure efficiency and safety of production, eliminate food waste and reduce use of energy.

Discover our solutions for food and beverages processing.

Retail & hospitality

For maintaining high product quality, productivity, safety and overall well-being of the staff, customers and contractors, and to achieve operational cost efficiency and reduce environmental footprint, food retail needs to be equipped with reliable and stable carbon dioxide monitoring instruments that offer low cost of ownership. For example, refrigerator leakage can be controlled using our probes with a unique certified technology.

Discover our solutions for food retail.

Food waste to value

The agricultural waste from primary production and food waste from the processing can be used to produce biogas. As by-products of the anaerobic digestion, high nutrient-content fertilizer is received and can be used by farms to replace resource-heavy fertilizers. The biogas, in its turn, can be used to generate electricity and district heating.

Moreover, the biogas can be upgraded to fuel-grade biomethane.

Discover our solutions for biogas and biomethane production.

Take an extra bite on the topic!

Join our Future of Food webcast

Dive into the details in Food Science eBook

Our solutions for the future of food

Read more about the food of today and the future

Why choose Vaisala?

Vaisala is a leading provider of industrial measurement and instrumentation solutions for the food, beverage, and agriculture industries. We have over 80-years’ experience in designing and manufacturing reliable, high-quality instruments and can help you achieve efficiency and sustainability with accurate, high-precision control and monitoring equipment that complies with the strictest hygiene requirements. All Vaisala products are manufactured under strictly controlled conditions at our manufacturing facility in Finland.