Cleanroom Environmental Monitoring

Reduce the risk of out-of-specification conditions and help keep your cleanrooms audit-ready and compliant.

High-Technology Cleanrooms

Cleanrooms and other critical environments require high-performance environmental measurements to operate consistently and within specifications. Humidity and temperature measurement can be especially challenging in a cleanroom environment.

Vaisala’s highly accurate instruments and robust solutions address measurement challenges and help keep your cleanroom facilities running smoothly. With state-of-the-art measurement technology, expert guidance, and a wide range of services to support your cleanroom operations, our products measure, monitor and record: humidity, dewpoint, temperature, pressure and more.

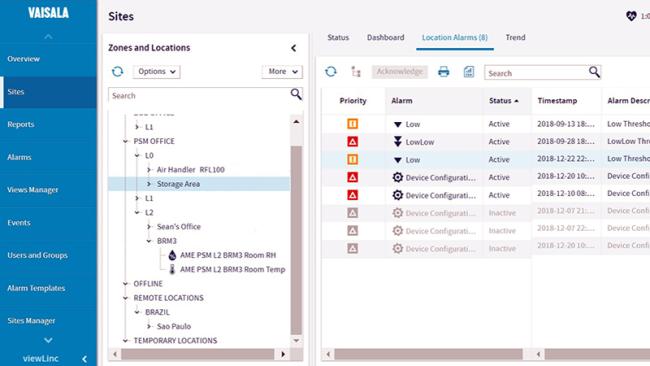

Cleanroom continuous monitoring

Learn more about the Vaisala viewLinc continuous monitoring system for cleanrooms.

Vaisala's CAB100 is an industrial cabinet that integrates Vaisala data loggers and transmitters with viewLinc. Cabinets can be pre-configured to your cleanroom's requirements and include safety barriers when needed. Measured parameters include humidity, temperature, differential pressure and more.

“In the case of the CAB100, just based on past experience of cleanroom monitoring systems, I estimate most systems would take up about four times the space as the Vaisala CAB100. That small footprint and the fact that it’s pre-configured make it very convenient."

Dan Gabrault, LSNE Plant Engineer

Cleanroom Related Products

Barometric pressure measurements with Indigo520 Transmitter

Vaporized Hydrogen Peroxide, Humidity and Temperature Measurement HPP270 Series

viewLinc Monitoring, Alarming and Reporting Software

VDL200 Data Logger

CAB100 Industrial Cabinet for continuous monitoring systems

VaiNet Wireless Temperature & Humidity Data Logger RFL100

VaiNet wireless CO2 data logger RFL100

CO₂ Probe GMP251

Indigo200 Series Transmitters for Vaisala smart probes

Humidity and Temperature Transmitters HMT120/130

Humidity and Temperature Probe HMP1