Cane and beet sugar milling and refining

Edible sugar manufacturing is a delicate process that requires process control and instant, accurate Brix (massecuite solids content) measurement of raw and in-process liquids for best product quantity and quality, measured with for example mean aperture (MA) and coefficient of variation (CV). Only high-quality liquid and crystal sugars are acceptable. In crystal sugar manufacturing, the absolute goal is to produce the maximum amount of even quality crystals, avoiding fines and conglomerates.

Efficient raw sugar processing to refined sugar

Sugar production involves two distinct operations: processing sugar cane or sugar beets into raw sugar and processing the raw sugar into refined sugar.

As sugar refining is a highly energy-intensive process where raw juice is subjected to multiple processing steps to remove impurities, the right process control tools help to maximize yield and minimize the cost of production. Overall, the sugar industry is a large water consumer as each production step requires water. The water and energy consumption during manufacturing can be significantly reduced, contributing to mill's or refinery's sustainability, by using modern technology equipment, such as Vaisala Polaris™ process refractometer.

Cover process conditions from liquid phase to massecuite

Sugar crystallization is often the main production process, and mass-producing quality and constant sugar at a competitive price require robust measurement devices that are not affected by varying process conditions from the liquid phase to massecuite nor by increasing crystal content during a strike.

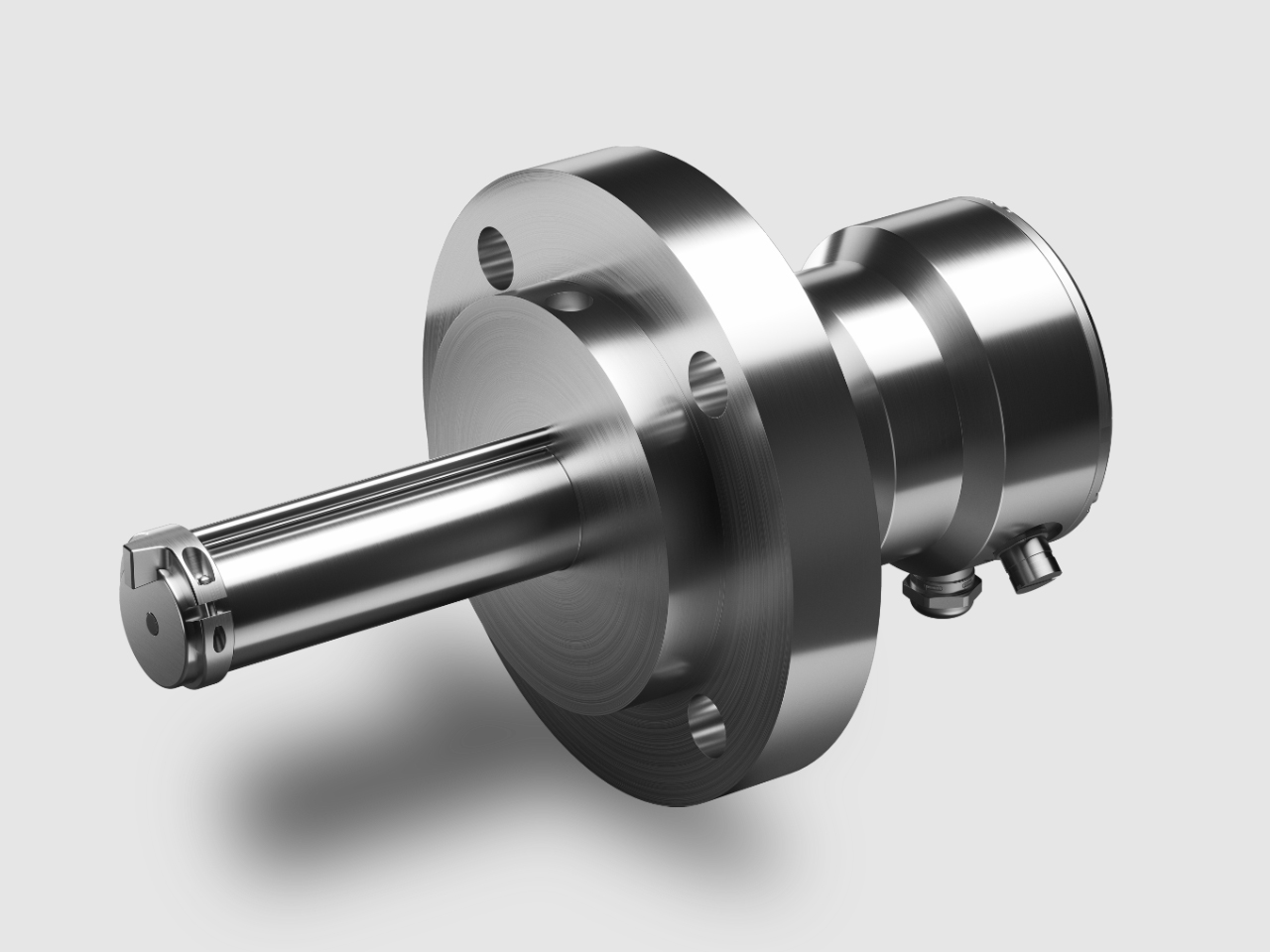

Supersaturation is the driving force of crystal growth, and the speed of crystallization depends on this multivariable function of several parameters. Supersaturation has an optimal range, where sugar crystals grow evenly and widely. Outside the range, the crystals will stop growing and might even melt or start to form new crystals spontaneously creating fines and conglomerates requiring reprocessing. The Zutora SeedMaster-4 is a unique device specifically created for sugar crystallization, providing the parameters necessary for sugar crystallization.

Online data provided by the SeedMaster instrument:

- Supersaturation

- Massecuite solids content (%)

- Crystal content (% vol.)

- Crystal size (mm)

- Mother liquor purity (%)

- Mother liquor concentration (%)

- Temperature (°C or ºF)

- Massecuite level (%)

- Massecuite density (kg/m3)

Measure accurately Brix and concentration inline

Vaisala Polaris refractometers and the Zutora SeedMaster-4 provide:

- Increased quality of liquid and crystal sugars

- Sugar products precisely according to recipe

- Assurance that liquid bulk sugar and molasses meet specifications

- Optimized extraction process by minimizing the usage of water which needs to be evaporated at a later stage

- Energy savings by adapting product flow to the capacity of the evaporators

- Control over feed juice to adjust the concentration with the capacity of the separation columns extending the intervals

- between recovering cycles and prolonging the lifetime of the columns

- Monitoring tool of supersaturation over the complete strike of crystallization

- Implementation of automatic and accurate seeding of the vacuum pan.

Applications in beet sugar milling and refining

Measure Brix accurately and inline in all beet sugar miling and refining processes, including extraction, evaporation, crystallization and centrifugation (desugarization) and chromatographic separation for best yield and product quality with savings on energy and production costs.

Download our application notes for more information.

Beet sugar processing

Vaisala Polaris process refractometer is used throughout the processing for optimization and to ensure efficiently working subprocesses and sugar beet mill and refinery.

Beet sugar extraction

Control extraction process for efficiently working process and mill

Beet sugar evaporation

Control steam flow and achieve constant juice concentration in evaporation stages

Beet sugar crystallization

Yield good quality sugar crystals without fines and conglomerates

Green syrup and molasses

Final molasses concentration quality, higher efficiency of desugarization process

Desugarization of molasses by chromatographic separation

In-line and real-time Brix measurement to improve the chromatographic separation and successfully recover betaine

Applications in cane sugar milling and refining

Measure Brix accurately and in-line in all cane sugar milling and refining processes, including affination, decolorization, evaporation, crystallization and recovery process for best yield and product quality with savings on energy and production costs.

Download our application notes for more information.

Cane sugar processing

Vaisala Polaris process refractometer is used throughout the processing for optimization and to ensure efficiently working subprocesses and cane sugar mill and refinery.

Cane sugar affination

Measure real-time the concentration of the liquor to clarification, implement process monitoring and control during the affination process.

Cane sugar decolorization

Increase yield, control wash for the sweet water washing line, detect the interface between sweet water ad syrup, automate control of regeneration process

Cane sugar evaporation

Ensure high-quality product with continuous Brix measurement of juice and syrup

Cane sugar crystallization

Yield good quality crystals without fines and conglomerates monitor supersaturation, implement automatic or manual seeding

Cane sugar recovery

Final molasses, dilution concentration control, molasses separation control, wastewater line monitoring and seeding point control

Applications in by-product processing

Measure Brix concentration of sugar or molasses, monitor crystallization process for quality yield.

Download our application notes for more information.

Citric acid production

Maintain target concentration of sugar or molasses and citric acid, monitor crystallization process

Applications in side-stream treatments

Monitor Total Dissolved Solids (TDS) and detect sugar shots or excessive amount of sugar in boiler feed water prior damages occur, monitor and control accurately, continuously and in-line the organic load (TOC) content in effluent or sweet-water streams.

Download our application notes for more information.

Sugar leakage detection in boiler feedwater

Detect sugar shots in the feed water prior equipment damage occur

Total Organic Carbon (TOC) monitoring and control in wastewater streams

Measure Total Organic Carbon (TOC) accurately and in-line and create control strategy with the help of Dissolved Solids (SD) measurement

Maximum productivity and safety in hazardous areas

The industry-leading Vaisala Polaris process refractometers offer Ex-certified product versions for hazardous areas.

Depending on selected product option, the refractometers are designed to be installed in either

IECEx/ATEX Zone 0/1 (North America Class 1 Division 1) or Zone 2 (Class 1 Div 2).

The Polaris Ex-versions are Indigo520 compatible to secure maximum productivity.

The Indigo520, and the associated IS equipment in case of Zone 0/Class 1 Div 1, is placed in the safe area.

Can't find your application?

Only some examples of our refractometer applications are listed here. There are still hundreds more!

Our application experts will help you. Tell us a bit more by filling the form or contact us.

The advantages of liquid concentration measurement over density measurement

eBook for sugar refineries

The primary goal of beet and cane sugar production is to ensure ideal sugar crystals. For this, several critical process parameters must be followed. The eBook provides knowledge on verified practices for optimizing sugar crystallization and producing uniform sugar crystals while reducing energy consumption and minimizing production costs.

Download the eBook to learn more.

White papers and Technical papers

Measuring massecuite solids content and mother liquor concentration in vacuum batch pans

Technical paper for Sugar Industry Technologists S.I.T. 2019 conference

Crystal growth and crystallization control tactics in industrial sugar crystallizers

On-Line monitoring and control of supersaturation and other massecuite parameters in vacuum pans: A control engineering approach

Sugar crystallization: Look for the devil in the details, part 1

Sugar crystallization: Look for the devil in the details, part 2

SeedMaster 2: A universal crystallization transmitter and automatic seeding device

Resources

Cane and beet sugar milling and refining related products

Sugar crystallization: reach target CV and MA with advanced process control

Vaisala Polaris™ PR53GC and GCEX Compact Process Refractometers for ordinary and explosive areas

Vaisala Polaris™ PR53GP and GPEX Probe Process Refractometers for ordinary and explosive areas

Liquid concentration measurement

Vaisala offers a wide range of products tailored to liquid measuring needs of different industries.

Learn more about the refractometer technology and its applications, and visit the library of product related assets.