Incubator Measurement and Monitoring

Monitoring, Validation and Mapping in Incubators and Test Chambers

One of the most important devices in producing and researching biopharmaceuticals is the CO₂ incubator, used for cell culture processes in many applications, including antibody production, tissue engineering, viral vaccine research, reproductive technologies, cell and gene therapies, and toxicity studies. To be effective, incubators must mimic the environmental conditions of a living body (in vivo) to enable successful cell growth in media within the chamber (in vitro). Culturing cells requires not only ideal conditions in the media used, but also in the incubator chamber as part of a robust contamination control strategy (CCS).

Accurate measurements mean repeatable processes & a successful CCS

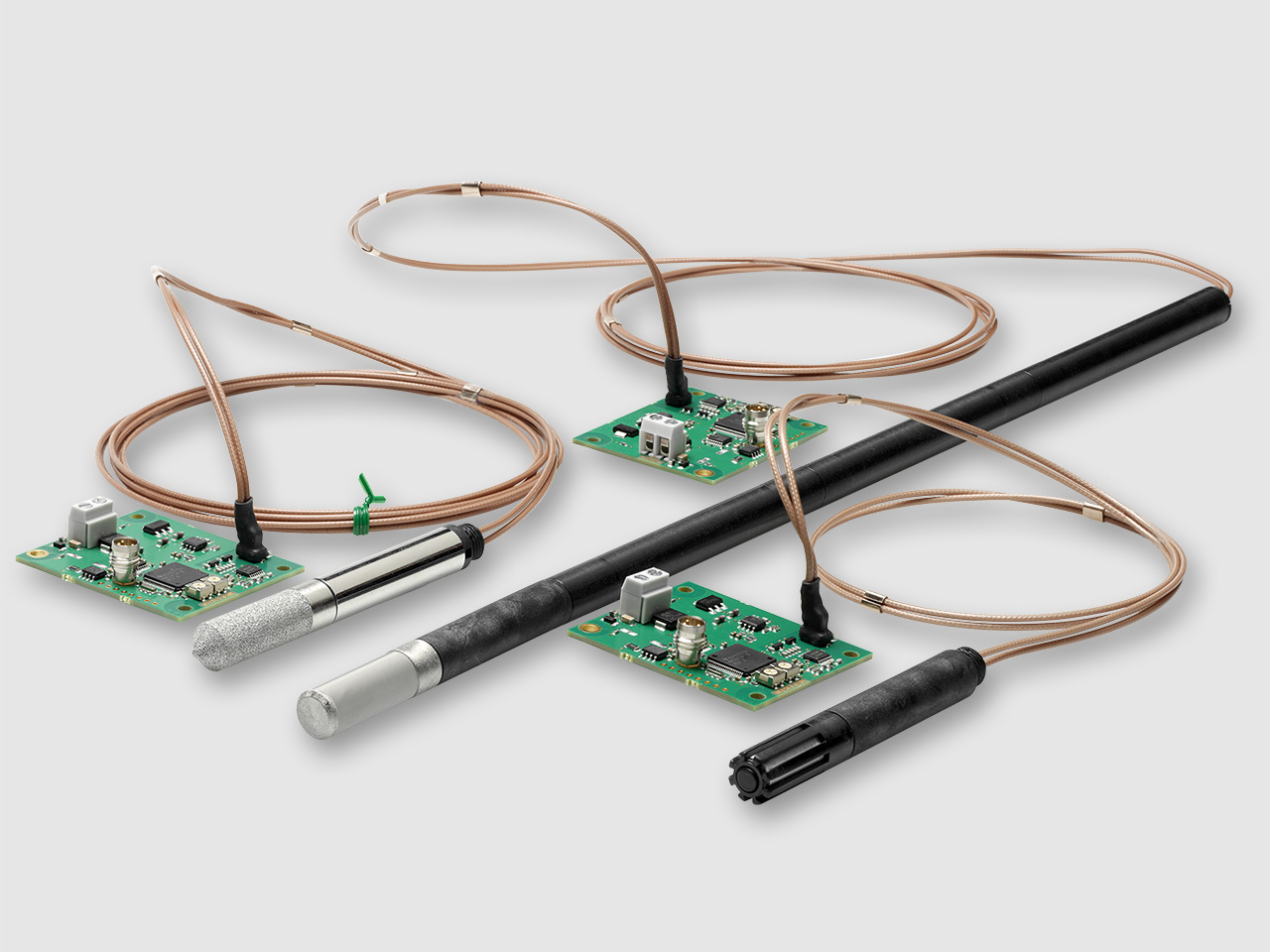

For carbon dioxide within incubators, the GMP251 CO₂ probe is an ideal solution. Based on Vaisala’s CARBOCAP® technology, it ensures measurement stability—critical for both process repeatability and effective contamination control. The CARBOCAP sensor features a unique infrared (IR) light source, extending probe lifetime. The GMP251 probe also calculates temperature and pressure compensations, important for any gas measurement, and the sensor head can be heated to prevent condensation—further supporting your contamination control strategy.

Wireless monitoring simplify installations

In the latest adaptation of GMP251 probe technology, the probe is connected to a wireless data logger to provide easier installation and send real-time and historical data to the viewLinc Continuous monitoring system or viewLinc Cloud. As the software component of this system, viewLinc provides local and remote alarming, real-time trend data, and reports for compliance with regulations.viewLinc monitors multiple parameters, including temperature, relative humidity, CO₂, differential pressure, and door status, sending alarms via text, email, or local display to ensure rapid response to any deviation that could impact contamination control.

The RFL100 CO2 data logger uses Vaisala’s proprietary wireless technology VaiNet to achieve wired-equivalent connectivity and superior signal strength to 100 m (330 ft.). The RFL100 carbon dioxide data logger can measure CO2 %, CO2 % with temperature, or CO2 % with temperature and humidity. Designed for incubators, the RFL100 includes probe-mounting options for secure, flexible placement, supporting your CCS by enabling optimal monitoring locations. Optional heat-resistant cables simplify heat sterilization, as only the probe needs to be removed. Easy removal also allows for straightforward calibration, supporting both compliance and contamination prevention.

What Makes Vaisala’s CO2 Sensors Unique?

In a word, calibration. Vaisala CO2 transmitters are individually adjusted and delivered with traceable calibration certificates, ensuring measurement accuracy is verified and documented for regulatory compliance—critical in pharmaceutical and biotech environments where precise gas control directly impacts product safety and process validation. Vaisala uses a single-beam and dual-wavelength NDIR (Non-dispersive infrared) technology for measuring CO2. This patented CARBOCAP® technology is used in all its CO2 sensors. This technology incorporates a unique tunable band pass filter that was developed by Vaisala and is manufactured in our own state-of-the-art cleanroom.

Incubator Measurement and Monitoring Related Products

Indigo500 Series Transmitters

Indigo200 Series Transmitters for Vaisala smart probes

Indigo80 handheld measurement device

CO₂ Probe GMP251

CO₂ Probe GMP231

VaiNet wireless CO2 data logger RFL100

viewLinc Monitoring, Alarming and Reporting Software

VDL200 Data Logger