Ensuring accurate humidity measurement in industrial processes

From the automotive industry to food production and from pharmaceuticals to steel or chemicals production, humidity measurement is a key part of many industrial processes. With potentially hundreds or even thousands of measurement points needed, ensuring stable, precise, and reliable measurement is extremely important.

This becomes more difficult in environments with high relative humidity (over 90% RH). In high relative humidity, all objects, including humidity sensors, are likely to be at a temperature close to saturation. In such an environment the vapor pressure gradient is not sufficient for effective evaporation of liquid water from the sensor surface. The sensor may stay wet for a several minutes or more, causing a prolonged measurement outage even after the environment is no longer saturated.

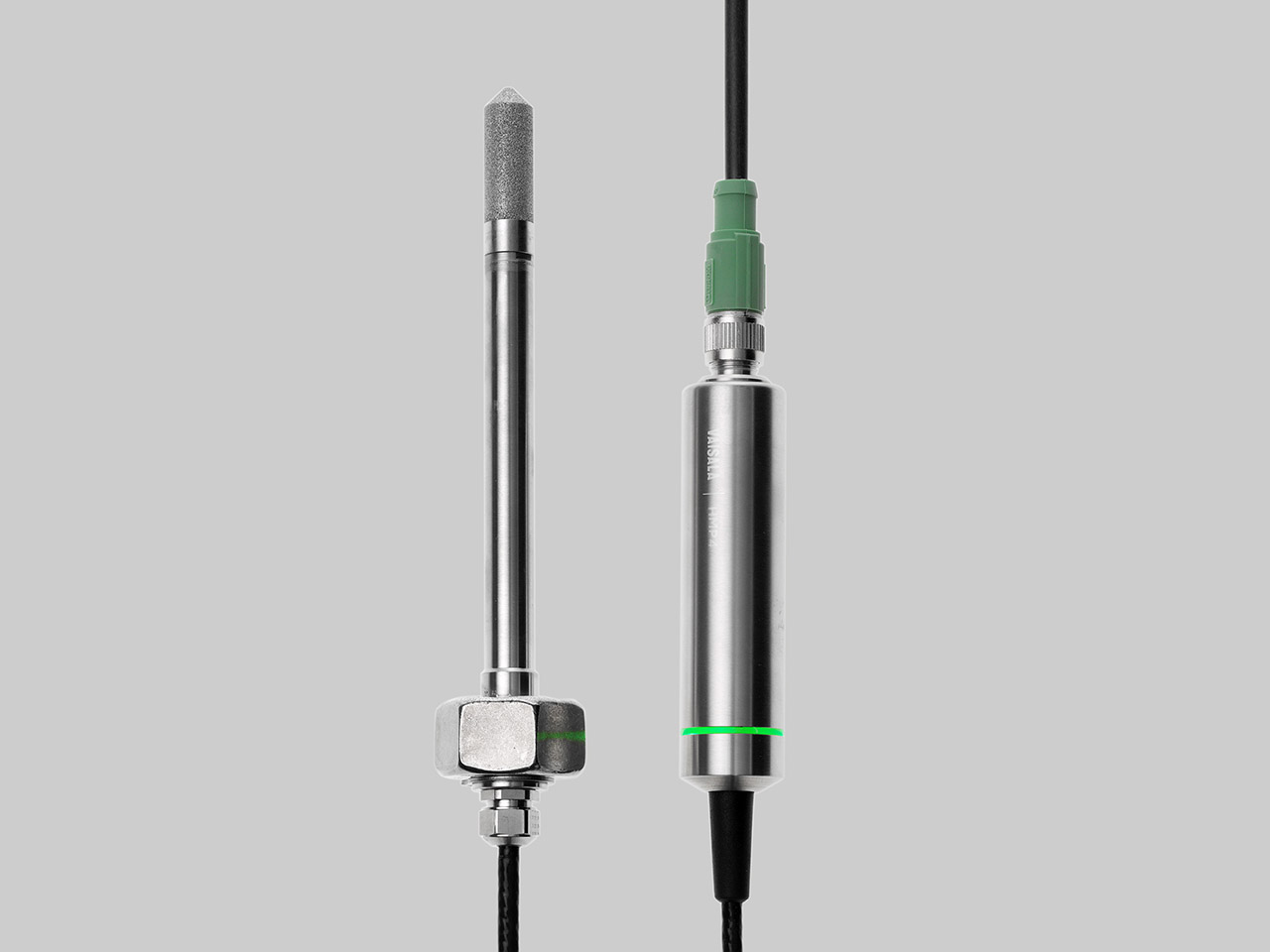

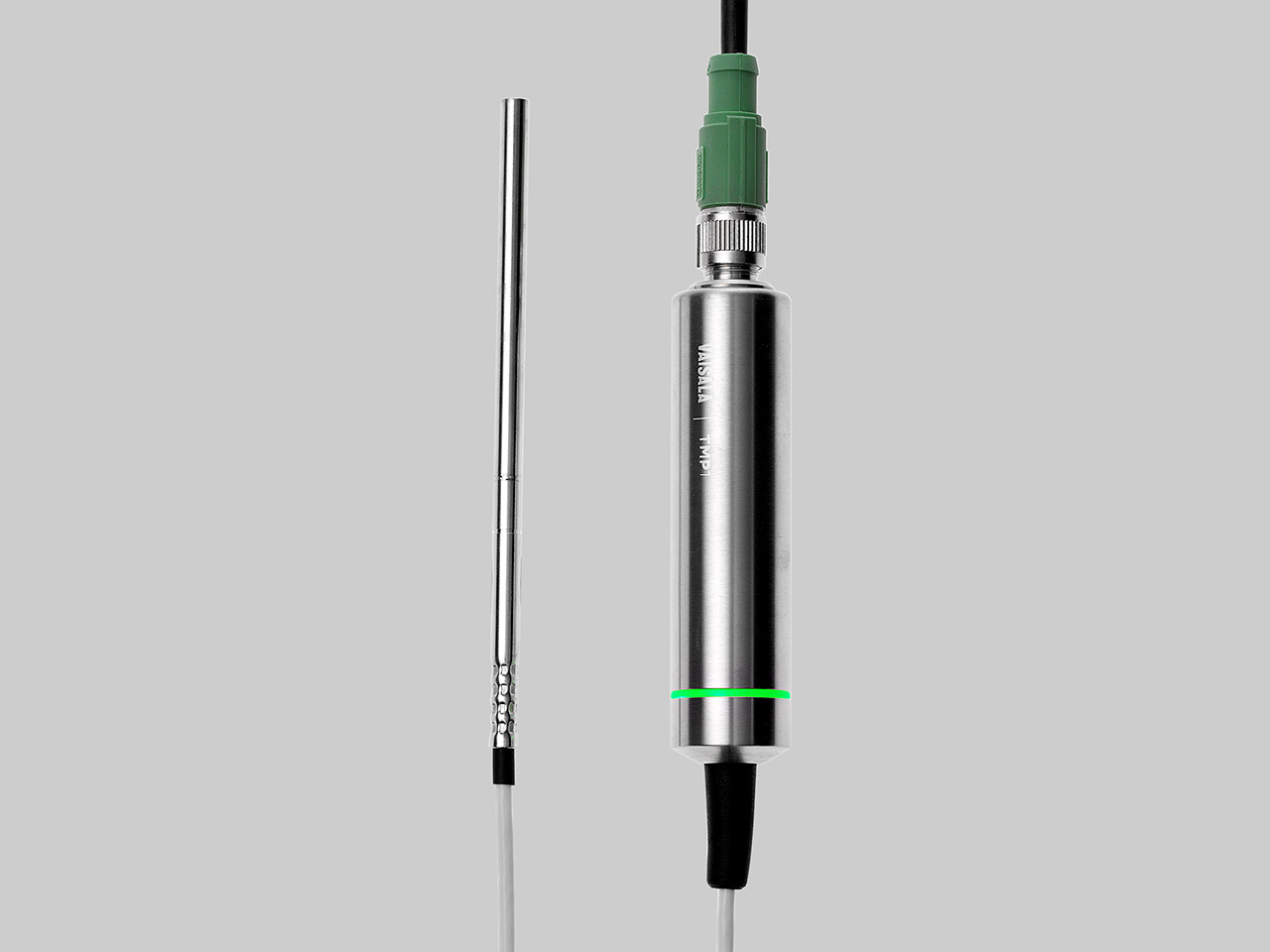

Modular probes and transmitters

In order to ensure stable and reliable measurement for tough industrial environments, Vaisala created the Indigo500 series of top-of-the-line, modular transmitters that pair with our industry-leading measurement probes. Solutions are available for all industrial and even outdoor measurement applications, including humidity probes with Vaisala warmed probe technology for reliable and accurate measurement even in environments with 100% relative humidity. The Indigo500 series also supports probes for temperature, dew point, moisture in oil, carbon dioxide (CO2), and vaporized hydrogen peroxide (H2O2) measurement, offering users a great deal of measurement flexibility.

Whatever the application, all Indigo probes are extremely accurate and reliable with excellent long-term stability, allowing you to detect even the weakest signals to make better and more timely decisions based on accurate data.

Introducing the Indigo510

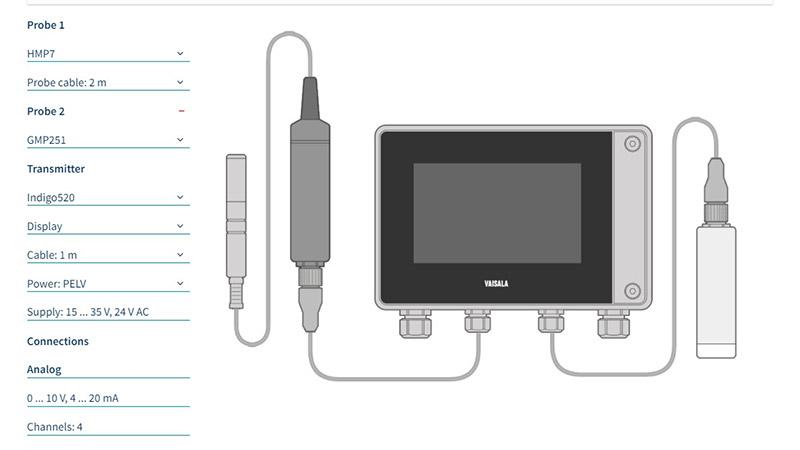

The first product in the Indigo500 range was the Indigo520, which offers the widest range of customization options and features, including support for two probes. It was designed for use in tough industrial environments, with a highly robust metal casing that has been proven in reference cases worldwide. For customers that don’t require the full range of functionality offered by the Indigo520 and who only need one probe, we now offer an equally robust alternative.

The new Indigo510 builds on the same platform and includes the same metal casing, software, display, and modularity as our flagship Indigo520 product. The features include modular support for a single Vaisala probe (meaning the probe type can be changed if needed), DC input, and two analog outputs. While the build quality and industry-leading measurement capability remain the same, the reduced feature set translates into a more streamlined price point. This makes the Indigo510 ideal for applications where precise and reliable measurement is needed for a single variable (like humidity) even under harsh conditions. Indigo510 customers will also benefit from regular platform updates and software improvements for their transmitter.

Combined with Vaisala Insight software, the Indigo series of transmitters and probes provides a solid ecosystem to ensure energy efficiency, safety, and end-product quality in your operations.

Read more about the Indigo series or contact us for more information.

Add new comment