Smart Drying

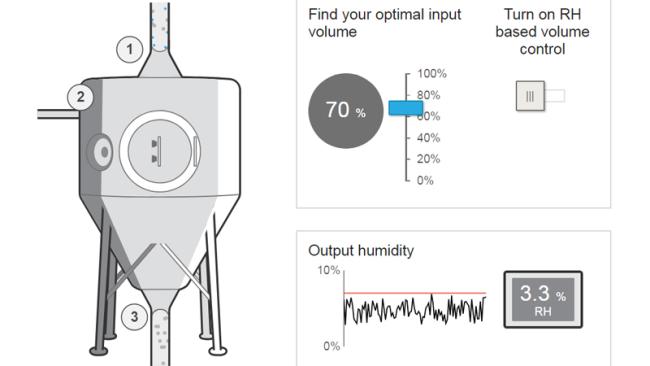

Optimize your drying process for energy efficiency and improved product quality

Has your drying process ever let you down? Poor energy efficiency, end-product quality issues, and equipment corrosion are common problems in drying processes lacking proper measurement instrumentation. The amount of humidity in air plays a critical role when drying everything from wood to ceramics to whey powder, and even compressed air.

A lack of accurate temperature and humidity measurement in industrial processes can lead to a variety of problems, for example, to overdrying which causes increased energy usage and additional costs that a company could do without. Higher energy consumption contributes to a larger carbon footprint, which can affect a company’s sustainability goals.

Insufficient drying can leave moisture in materials, promoting the growth of mold and mildew, which can be harmful to health and damaging to products. Underdried products may not meet quality standards, leading to customer dissatisfaction and potential returns.

Inadequate drying may increase maintenance costs because moisture can cause machinery to rust and deteriorate faster, leading to higher maintenance and replacement costs.

Products that are not properly dried may require additional drying time, causing delays in production schedules and delivery.

Addressing these issues requires careful monitoring and control of drying processes, investment in efficient equipment, and regular maintenance to ensure optimal performance.

Vaisala has the measurement instruments to solve your drying issues. For your industrial drying process, this means energy savings, reduced equipment stress and breakdowns, and improved end-product quality.

Drying applications

Compressed air

Compressed air that is clean and dry can be ensured by accurate dew point measurement instruments. By using stable dew point measurement you can also avoid over-drying and save energy.

Drying in battery manufacturing

Fluid bed drying

Spray Drying

Baking Oven Monitoring

Construction materials drying

Structural moisture measurements