Measuring Water Vapor in Drying Processes of Construction Material Manufacturing

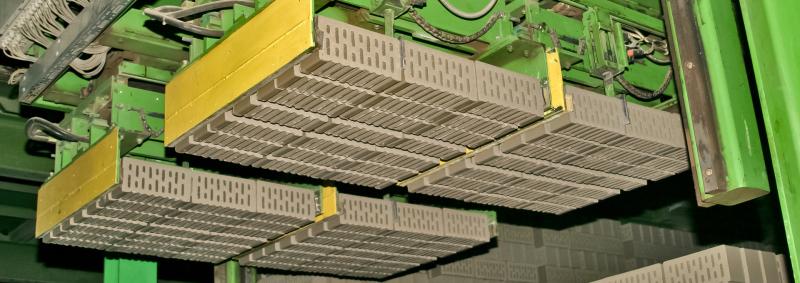

Drying is an essential process in the manufacturing of various construction materials like tiles, bricks and gypsum board. Typically the dried material is not measured directly, but rather indirectly through water vapor measurement of the process air.

Often times the challenge is not only to dry the material sufficiently to achieve the desired finished product characteristics, but to avoid overdrying which can result in wasted energy.

Vaisala’s product offering is designed to tolerate the harsh conditions in industrial drying processes. Several options are available to meet the various needs in very humid and high temperature applications. Scroll down to see the related products and case studies.

Construction material manufacturing related products

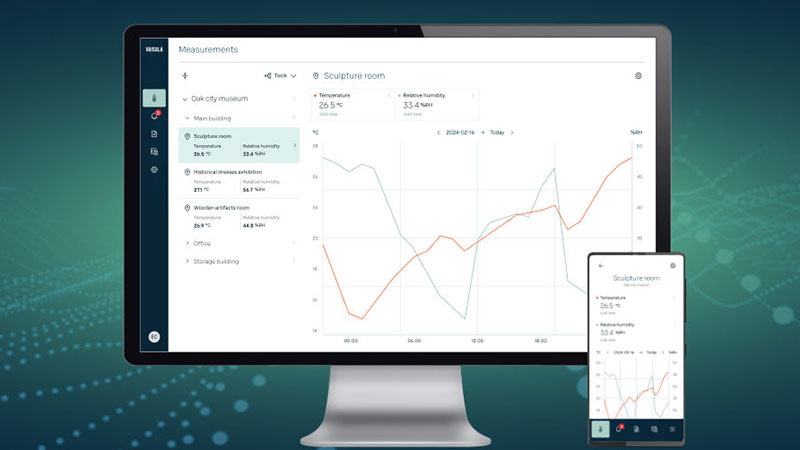

Jade Smart Cloud

Combining industrial-grade measurements with secure and reliable wireless monitoring, Vaisala Jade Smart Cloud brings new levels of proficiency and flexibility for professionals.

Insight PC Software

Vaisala Insight PC Software gives quick access to the configurations and data of the Indigo family measurement probes and other supported Vaisala devices.

CWL100 Wireless Data Logger

CWL100 Cloud Wireless Data Logger is part of the Vaisala Jade Smart Cloud monitoring system. It is used to monitor humidity and temperature in a wide range of environments.

Relative Humidity and Temperature Probe HMP7

Vaisala HUMICAP® Humidity and Temperature Probe HMP7 is designed for applications which involve constant high humidity or rapid changes in humidity

Relative Humidity and Temperature Probe HMP5

Vaisala HUMICAP® Humidity and Temperature Probe HMP5 is designed for high temperature applications such as baking ovens, pasta dryers, ceramics and industrial drying kilns where measurement performance and chemical tolerance are essential.