Indigo500 series transmitter improves control of malting process

As one of the world’s leading suppliers of high quality malt products, Viking Malt has investigated the advantages of continuous humidity monitoring inside the malting process at its facility in Halmstad, Sweden. Vaisala’s Indigo520 transmitter has been integrated with the plant’s control system, and after an initial trial of 3 months, Technical Manager Tony Öblom says: “Real-time access to humidity data has enabled tighter control of the malting process – improving quality whilst saving energy and improving profitability.”

Background

Malt is a key ingredient in the manufacture of beer, whiskey and many baking products. Viking Malt’s head office is in Finland, and the group operates 6 malthouses in Finland, Denmark, Sweden, Lithuania, and two in Poland, producing a combined total of over 600,000 tonnes of malt per year.

The majority of malting grain is barley, but wheat and rye may be used, as well as rice and maize. With its malthouses in northern Europe, Viking Malt enjoys a number of advantages. For example, the barley from its contract farms is of good quality with excellent malting characteristics. In addition, cold winters kill off pests and diseases, and the crops grow quickly in the midnight sun, which means that they require less pesticide.

The malting process

Malting involves the initiation, management and cessation of germination. This is achieved through the careful and precise control of in-chamber moisture, temperature and sometimes carbon dioxide. Good beer might be a matter of personal taste, but the consistency of flavor and other characteristics depend on the use of high quality malt.

Tony says: “At Viking Malt we work very hard to ensure the production of consistent, high quality malts. This is achieved through the careful selection and management of raw materials and by monitoring and controlling production as carefully and precisely as possible.”

The malting process has three main phases, which combined can vary between seven to ten days, depending on the characteristics of the raw materials and specification of the produced malt. The three phases are:

- Steeping – the grains are washed and their moisture content is increased in the steep tanks to stimulate germination. Steeping normally involves a combination of wet and dry periods of different lengths.

- Germination – as the seeds germinate they produce enzymes. For example, amylases convert starch in the seeds to fermentable sugars and proteases break down protein.

- Kilning – in the final part of the process, the ‘green malt’ is dried and heated in a kiln to meet the requisite specification.

At the beginning of the malting process, the humidity inside the kiln is likely to be 100% at 60 to 65 °C, whereas the final kilning is likely to be between 80 and 95 °C with a target humidity of 4%.

The importance of monitoring

As a producer of 65 different types of malt, Viking Malt monitors its feedstock and production processes very closely to ensure consistency and compliance with specifications for features such as moisture, color, flavor, protein and enzyme content. Samples are frequently taken from production for testing in the onsite laboratory.

“The results can take around 6 hours,” Tony explains. “For some parameters this is acceptable, but in order to optimize process control, we need real-time data, so I conducted research to discover potential solutions and learned that my colleagues in Finland were successfully trialing a Vaisala Indigo520 transmitter.

“Continuous humidity data enables us to determine the precise moment at which the malting process is complete. Not only does this help to assure product quality by making sure that we are not under-drying or over-drying; it also helps us to save money because over-drying is a waste of energy, and increases the cost of the final product.”

According to the Viking Malt CSR Report, 2019: “Energy efficiency is a guiding principle in the planning of our plant design, investments, production, logistics and sourcing of energy product and services.” The implementation of the Indigo520 transmitter therefore helps to fulfil this objective as well as another which seeks to “increase the speed of innovation especially in information and communication technologies.”

Continuous, reliable measurements with the Indigo520 transmitter also provide a complete record of production, with no interruptions from calibration and maintenance activities.

Monitoring technology

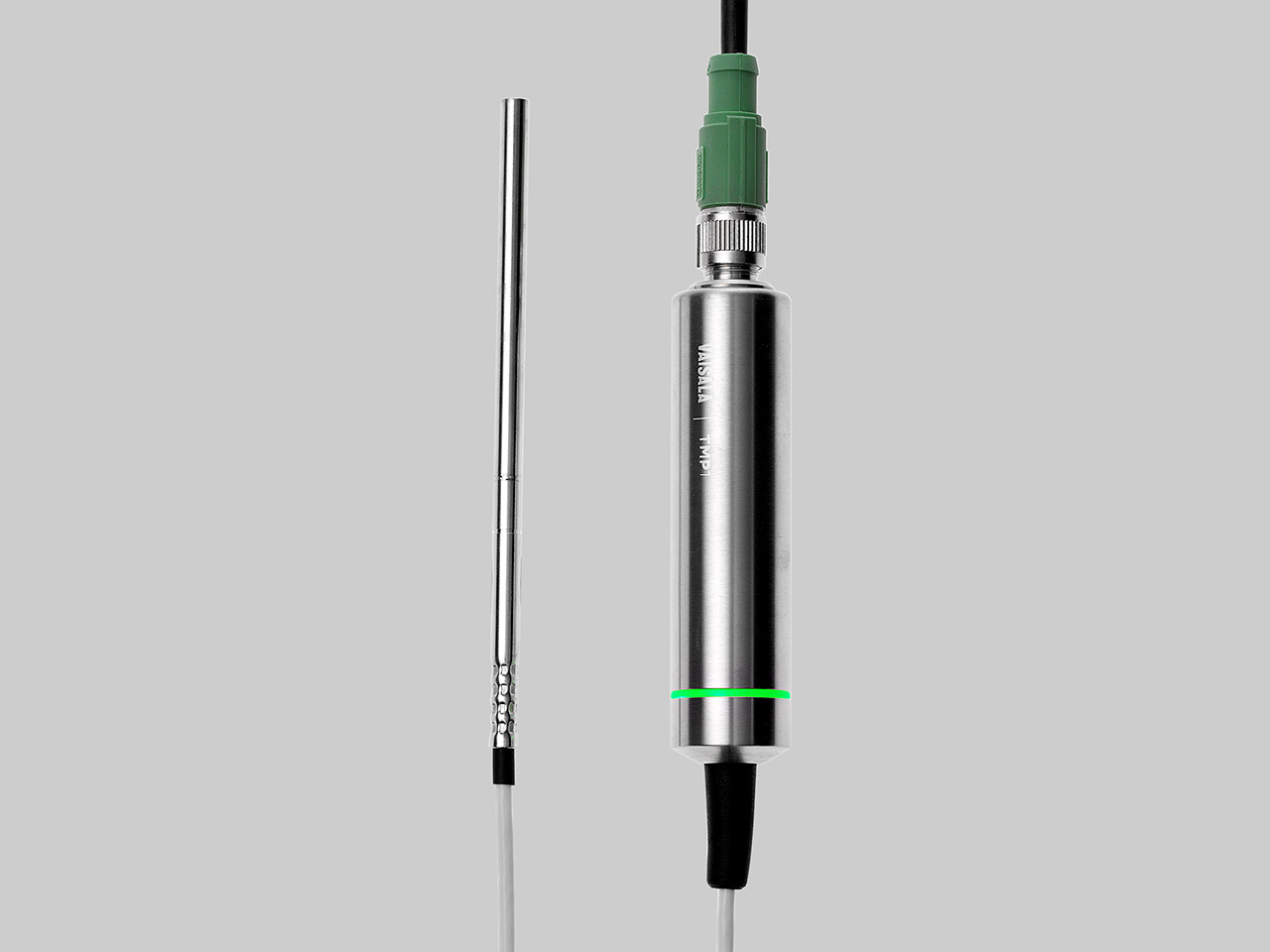

The Indigo520 transmitter collects data from a Vaisala HMP7 humidity probe, which utilizes heating technology, and is specifically designed for high-humidity applications. Combined with a TMP1 temperature probe, the system provides stable and reliable relative humidity measurements in the final kiln.

The Indigo520 is compatible with Vaisala’s comprehensive range of Indigo compatible smart probes for humidity, temperature, dew point, carbon dioxide, vaporized hydrogen peroxide, and moisture in oil measurements. It can accommodate two detachable measurement probes simultaneously, measuring the same, or different, parameters at the same time. The transmitter has an IP66- and NEMA 4 -rated robust metal enclosure, and a touchscreen display made of hardened glass. This local display provides onsite staff with quick and easy access to live data, and by connecting the transmitter to the control system, Tony and his team are able to view readings wherever they are and at any time of day or night.

Download the complete customer story or Contact us for more information.