Inline dry solids content measurement in chemical recovery process

Vaisala provides in-line dry solids content and density measurement technology for black liquor and green liquor at the kraft chemical (sulfate) and chemi-mechanical pulp production processes. Vaisala Polaris PR53SD Process Refractometers and digital divert control systems are used in the energy recovery from black liquor recovery boiler to accurately measure solids of the black liquor and green liquor. The key purpose of our technology is to significantly improve energy and materials recovery and utilization.

Optimizing energy-intensive operations

The kraft recovery process has three main functions: minimizing the environmental impact of water material (black liquor) from the pulping process, recycling pulping chemicals, NaOH and H2S, and co-generating steam and power.

We provide retractable Vaisala Polaris PR53SD Process Refractometers for measuring dry solids, liquid density, concentration and Total Titrable Alkali (TTA) in chemical recovery process to optimize energy-intensive operations. As a result, the capacity of the evaporators can be increased, and the quality of white liquor can be improved by controlling continuously the TTA of the green liquor in the causticizing process. Furthermore, recovery boiler safety can be increased using a Digital divert control system in feeding black liquor solids to recovery boiler burners.

Typical applications in pulp mill unit operations

Black liquor to evaporators

The concentration of feed liquor from washers to evaporation can be kept constant by controlling the mixing liquor with the Process refractometer, thus allowing the capacity of the evaporators to be maximized. Using the refractometer in the intermediate stage the profitability can be increased in the form of minimized steam consumption

Green liquor TTA in causticizing

The quality of white liquor can be improved by controlling continuously the TTA of the green liquor in the causticizing process. Green liquor total titratable alkali (TTA) content can be controlled by addition of weak wash liquor dilution. TTA has a good correlation with Refractive Index nD, which provides an accurate measurement for the green liquor.

Black liquor to recovery boiler

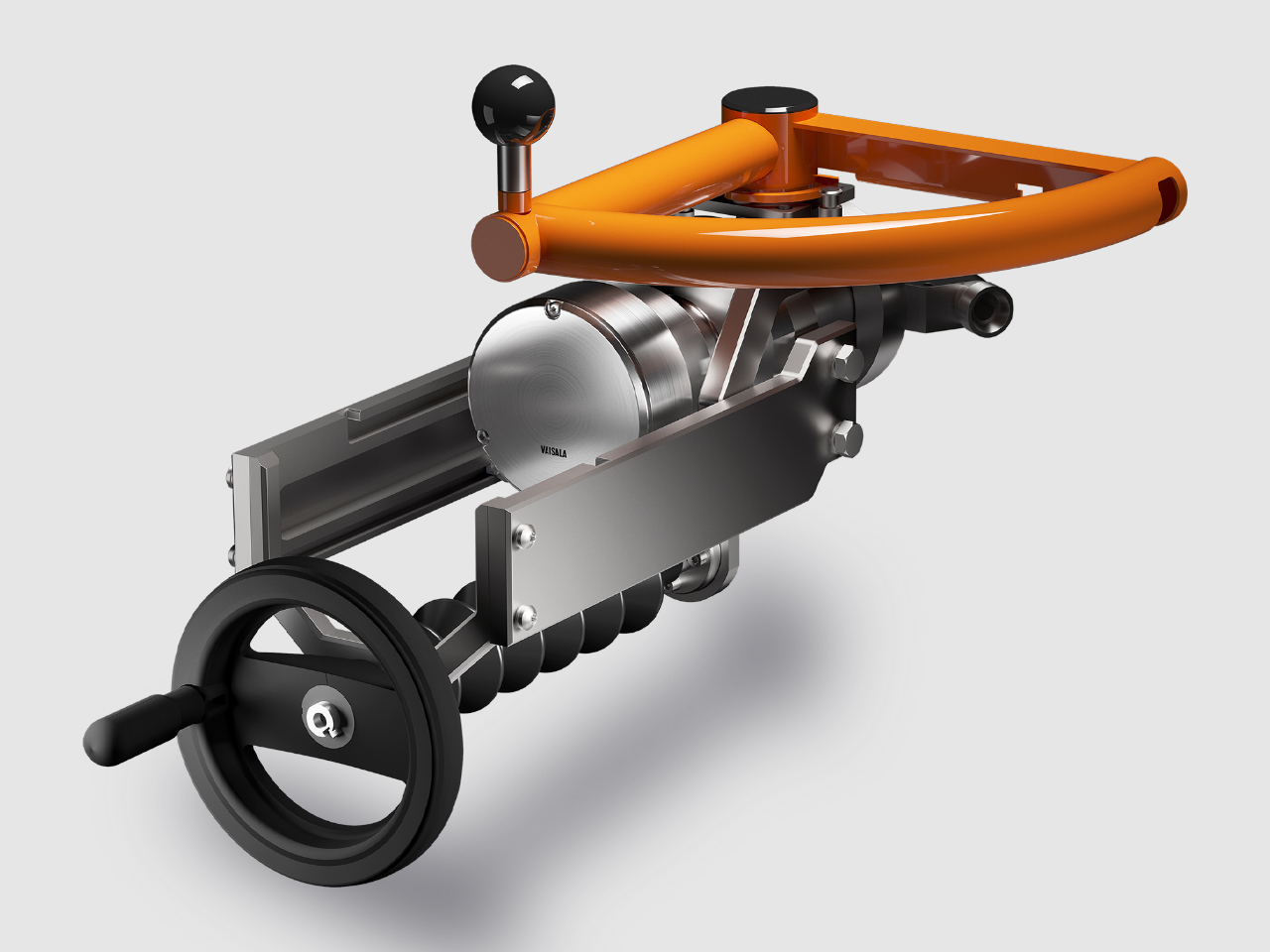

Feeding low concentrations of black liquor solids to a kraft chemical recovery boiler burner can cause a steam explosion. The Digital Divert Control system measures black liquor in to prevent dangerously low black liquor concentrations from reaching the boiler.

Applications in the pulp and paper processing

Kraft (Sulfate) Pulp Process

Sulfite Pulp Process

Paper Sizing Process

Can't find your application?

Only some examples of our refractometer applications are listed here. There are still hundreds more!

Our application experts will help you. Tell us a bit more by filling the form or contact us.

Chemical recovery process related products

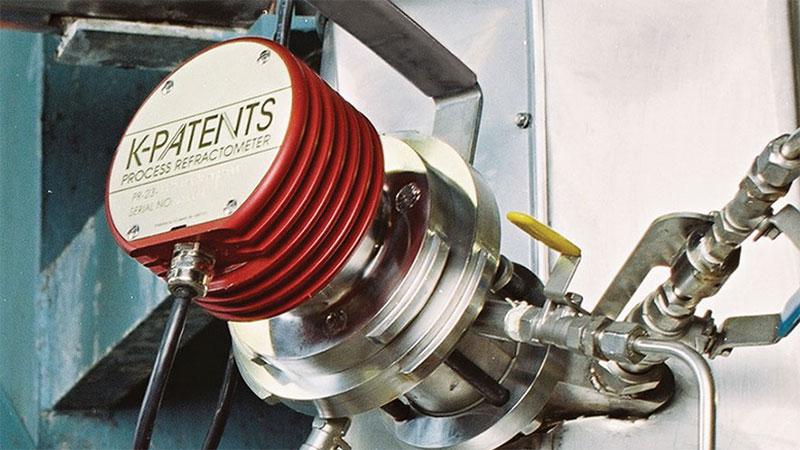

Vaisala Polaris™ PR53SD Process Refractometer

Vaisala K-PATENTS® Digital Divert Control System DD-23

Related resources

Liquid concentration measurement

Vaisala offers a wide range of products tailored to liquid measuring needs of different industries.

Learn more about the refractometer technology and its applications, and visit the library of product related assets.