Mapping validation studies are essential—but can be time-consuming. What if you could use those same sensors for more than just a one-time study?

In this eye-opening webinar, we explore the concept of continuous mapping—leaving high-density sensor deployments in place after validation to gain ongoing visibility into your environment.

You’ll learn how continuous mapping can:

- Reveal long-term trends and seasonal excursions that periodic studies might miss

- Strengthen data integrity, even if a sensor fails or loses connection

- Enhance environmental control and operational confidence

But what about cost?

We compare the actual expenses of continuous versus intermittent mapping strategies—and the findings may surprise you. If you're responsible for GxP compliance, warehouse monitoring, or environmental validation, this session offers valuable insights into optimizing both performance and budget.

Watch now to discover:

- Whether continuous mapping is truly cost prohibitive

- How to increase the value of your mapping studies

- Why better data could mean fewer compliance headaches

You can modify your preference settings or unsubscribe at any time here

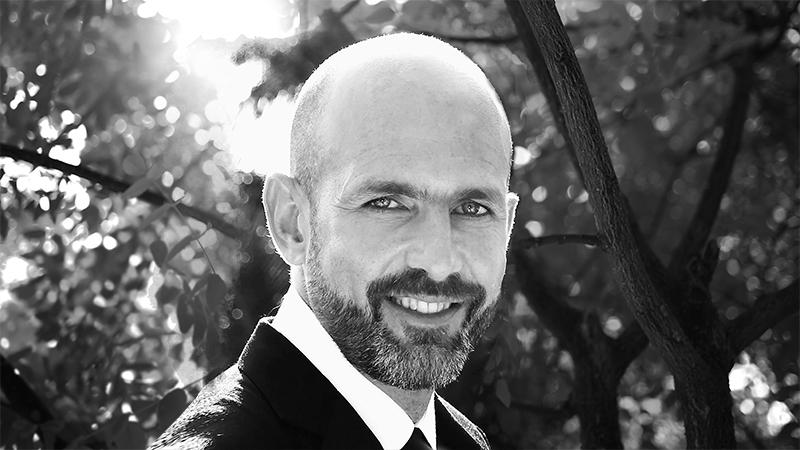

Webinar speaker

Paul Daniel, Vaisala

Paul Daniel is the Senior GxP Regulatory Expert at Vaisala. He has worked in the GMP-regulated industries for over 20 years helping manufacturers apply good manufacturing practices in a wide range of qualification projects. His specialties include mapping, monitoring, and computerized systems.

At Vaisala, Paul oversees and guides the validation program for the Vaisala viewLinc environmental monitoring system. He serves as a customer advocate to ensure the viewLinc environmental monitoring system matches the demanding requirements of life science and regulated applications.

Paul also shares his GMP experience through regular blog contributions, webinars, and seminars around the world. Paul’s expertise in the demanding GxP world is applicable to any industry where measurement is critical to product quality. Paul is a graduate of University of California, Berkeley, with a bachelor's degree in biology.

Your guide to Better Warehouse Mapping

Designed for regulated storage environments, this white paper provides step-by-step guidance for qualifying a warehouse in alignment with Good Distribution Practice (GDP) requirements. Backed by over 20 years of experience, it outlines how to plan and execute temperature mapping studies that withstand regulatory scrutiny—while improving efficiency and data integrity.

Contact our Validation Mapping Team

Get all your questions answered!