Dew Point Probe DMP6

for in-line measurement in very high temperature applications <350 °C

Vaisala DRYCAP® Dew Point and Temperature Probe DMP6 is designed for in-line humidity measurement in industrial drying applications with very high temperatures and a wide dew point range. A high temperature tolerance is achieved using a passive cooling set that conducts heat away from the probe and reduces the temperature to within the optimal range for the sensor.

DRYCAP®

DMP6 incorporates the Vaisala DRYCAP® sensor, which is accurate, reliable, and stable. The sensor is condensation-resistant and immune to particulate contamination, oil vapor, and most chemicals. Sensor warming minimizes the risk of condensation accumulating on the sensor. If the DRYCAP® sensor does get wet, it dries rapidly and recovers its swift response time. In low-humidity conditions the sensor will auto-calibrate to ensure accurate measurement.

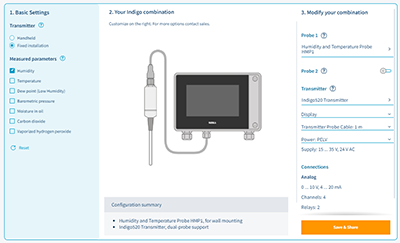

DMP6 is part of the Indigo family and is compatible with Indigo500, Indigo300 and Indigo200 series transmitters. It can be used with the Vaisala Insight PC software for data visualization, easy probe configuration, and self-calibration.

Features

- In-line measurement for humidity at temperatures up to +350 °C (+662 °F)

- Dew point measurement range -25 … +100 °C (-13 … +212 °F) Td

- Dew point measurement accuracy up to ±2 °C (±3.6 °F)

- Sensor purge provides superior chemical resistance

- Withstands condensation, oils, dust and most chemicals

- Modbus RTU over RS-485 for flexible connectivity

- Compatible with Indigo series transmitters

- Includes traceable three-point calibration certificate

- Long (two-year) calibration interval for easy maintenance

Key benefits

Measure dew point directly in very hot processes

DMP6 is built for in-line dew point measurement in very hot processes, between 100...350 °C (+662 °F). Best measurement performance is achieved at process temperatures between 100 °C and 350 °C. The cooling system has no moving parts, and requires no additional power or cooling utilities, so there is no risk of sensor damage due to mechanical cooling failure.

The installation is simple, as the probe can be directly placed in the process. With in-line measurement, there is no need for a sampling system or sample line trace heating.

Vaisala DRYCAP® Sensor for accurate and reliable measurements

The Vaisala DRYCAP® sensor is accurate, reliable and stable. It is condensation-resistant and is immune to particulate contamination, oil vapor, and most chemicals. Sensor warming minimizes the risk of condensation accumulating on the sensor. If the DRYCAP® sensor does get wet, it will rapidly dry and recover from getting wet. Due to the unique auto-calibration functionality accurate and stable measurement is ensured.

The chemical purge involves periodic heating of the sensor to remove harmful chemicals. In environments with high concentrations of chemicals and cleaning agents, it helps to maintain measurement accuracy between calibration intervals.

Use standalone or with an Indigo Transmitter

The DMP6 is part of the Vaisala Indigo family, so it can also be used with the Vaisala Indigo series transmitters. The transmitters offer various additional benefits such as display for data visualization, easy access to probe configuration, as well as more extensive options for automation system connectivity, supply voltage and wiring.

Built-in Modbus RTU over RS-485 output means that the DMP6 can be used as a standalone device, and can be easily integrated into third party systems.

Whether using the DMP6 standalone or with an Indigo transmitter, it can be connected to the Vaisala Insight PC software for easy field calibration, probe configuration and device analytics.

Indigo Selector

Discover your ideal Indigo compatible probe and transmitter combinations with the Indigo Selector tool.

Product documentation

More downloads

Product Resources

How accurate humidity measurement is helping Bühler’s customers bake more efficiently and consistently

Read how Bühler uses the DMP6 dew point measurement probe along with Indigo500 series transmitters to improve their baking ovens.