Industrial companies are continuing to take action to minimize their carbon emissions. Many are reducing their use of fossil fuels and switching to clean renewable energy. But what is the role of compressed air in all this?

Compressed air is a utility that requires attention

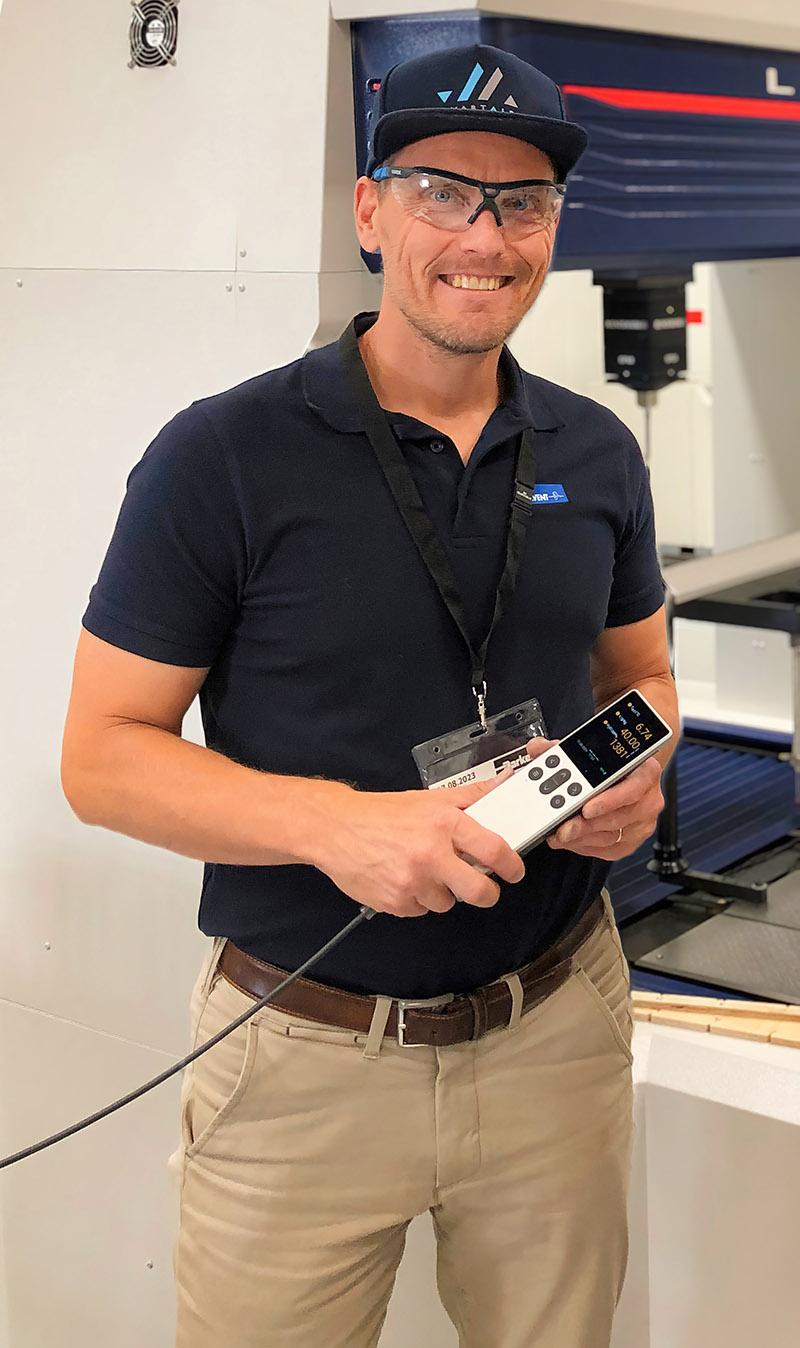

Sami Uusi-Erkkilä, CEO of SmartAir and Energy, points out that compressed air is an essential utility in the same way as electricity, steam, water, and other utilities are. However, it is often used wastefully without considering energy consumption or compressed air leaks.

“In many industrial surroundings, compressed air is often the second largest utility after electricity in terms of energy use. Therefore, the actions taken to minimize compressed air-related emissions really matter,” says Uusi-Erkkilä and continues: “Some of the key factors to consider are the sizing of the compressed air system, how much is invested in equipment quality, and how the system is maintained. Measurements, for example, play a key role in both the supply and demand side of compressed air.”

Uusi-Erkkilä also wants to draw attention to the important fact that an efficient system does not always lead to using less energy, meaning a more comprehensive approach is needed.

Developing compressed air as a utility

Antti Viitanen, Product Manager at Vaisala, agrees that you need to think about the whole production process in order to reduce fossil fuel-based energy use.

“You should start from the natural resources you are using. But if the energy source that powers your compressed air system cannot be changed to a clean alternative, you can still optimize factors related to the system life cycle”, he says.

Viitanen also lists some good questions to ask yourself about your compressed air system:

- How is the electricity that powers your compressed air system produced?

- Have you sized and planned the system properly for your needs?

- Have you selected quality compressors and dryers with integrated, high-quality dew point instruments?

- Are you operating the system at a suitable pressure level?

- Do you have a condition-based automated control system?

- Do you have a demand-oriented compressed air management system?

- Are you making data-driven decisions based on existing data?

- Are you identifying issues through regular follow-up?

- Can you recover and utilize the waste heat generated by the system?

- Do you maintain the system regularly?

- Have you trained your operators in how to operate the system safely and efficiently?

- Are you discussing further developments with your sustainability team?

Compressed air quality has multiple meanings even when it comes to moisture

Uusi-Erkkilä explains that there are different things to consider even when aiming to fix an isolated challenge such as the problem of moisture in compressed air:

“Most people working with compressed air acknowledge that moisture is harmful in a compressed air system. However, there are several reasons to dry the compressed air. Our thoughts are often about the equipment that uses compressed air and its functionality, but it is as important or even more important to be aware of how the compressed air treatment equipment functions. If there is a moisture-sensitive component or functionality in the location where the compressed air system is used, it is probably a quick fix with a small price to pay. But imagine a situation where the whole drying process of the compressed air treatment system runs with reduced power or is malfunctioning. This situation would affect all compressed air functions in the facility, whether it is a single compressed air pistol or an extremely sensitive compressed air measurement sensor. Depending on the industry and the size of the company, there may be tens or even hundreds of different compressed air consumers. This is why fixing the issues at the source is crucial.”

Uusi-Erkkilä sees that the green transition in compressed air means all activities aim at the systematic reduction of energy use, improving energy efficiency, and minimizing waste.

“Waste can mean a compressed air leakage, a malfunctioning drying system with excessive drying, or wasted opportunities in the compressed air training culture within the company. When selecting a solution, you should take care to choose a measurement instrument that is suitable for your process, whether it is an adsorption dryer or a compressed air system with spot-checking needs”, concludes Uusi-Erkkilä.

Dew point measurement is an essential part of the green transition in compressed air

Viitanen points out that dew point measurement is one of the main ways to save energy in compressed air systems and thus in important part of the green transition.

“Dew point measurement allows you to optimize the drying process of compressed air instead of over-drying it. An optimized process with integrated dew point instruments can lead to a significant reduction in annual costs. With a handheld dew point instrument, you can also perform daily checks on the compressed air moisture level in almost any part of the process line. This not only prevents water leaks but also allows you to take action before there is a negative impact on the quality of your final product.”