High fiber quality and improved production capacity of Lyocell production process

Regenerated cellulose fibers, or rayon fibers are made by chemical modification of the cellulose in wood pulp and dissolving it in a solution into fine fibers.

Typical rayon fibers are viscose, cellulose acetate and Lyocell fibers.

Lyocell is often used in industrial applications due to its smoothness and good wet-strength.

How is Lyocell produced?

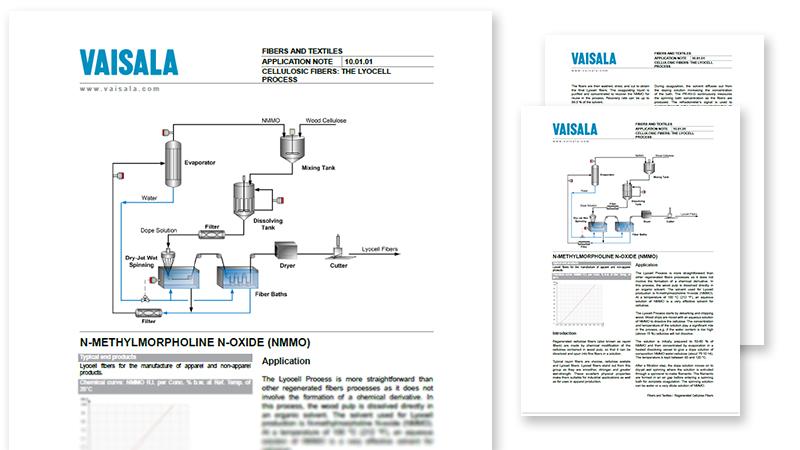

Lyocell is produced by dissolving wood pulp in an organic solvent such as N-methylmorpholine N-oxide (NMMO). The concentration and temperature of the solution play a significant role in the process, e.g. if the water content is too high (above 15%) cellulose will not dissolve. The solution is initially prepared to 50-60% of NMMO and then concentrated by evaporation in a heated dissolving vessel to obtain a dope solution with NMMO:water:cellulose (about 76:10:14) composition.

After filtration, the dope solution moves on to dry-jet wet spinning where the solution is extruded through a spinneret to make filaments. The fibers are then washed, dried, and cut to obtain the final Lyocell fibers.

The Vaisala PolarisTM process refractometer continuously monitors the concentration of the dope solution and the solvent at various stages of the Lyocell production process. This guarantees maximum productivity and high fiber quality.

Learn the details of the Lyocell production process from the application note.

Download the application note in PDF by filling the form.

Go back to all Chemicals & Allied Products applications

You can modify your preference settings or unsubscribe at any time here