Compressed air control can dramatically cut your operating costs

Compressed air is a vital resource in a variety of different application environments, from manufacturing plants to medical facilities. But without proper moisture control enabled by appropriate measurement instruments, manufacturing compressed air and maintaining its quality can result in excessive energy costs.

Don’t forget to optimize your drying process

One of the largest drivers of energy costs in compressed air systems is drying, so optimizing this process can lead to significant cost savings. Over-drying the air will mean higher energy bills, while under-drying can result in problems that are expensive to fix. Condensation of humidity in the compressor and compressed air pipelines can cause machinery breakdowns and contamination of the air; it can also lead to freezing or blockages.

How dew point measurement can cut your energy consumption

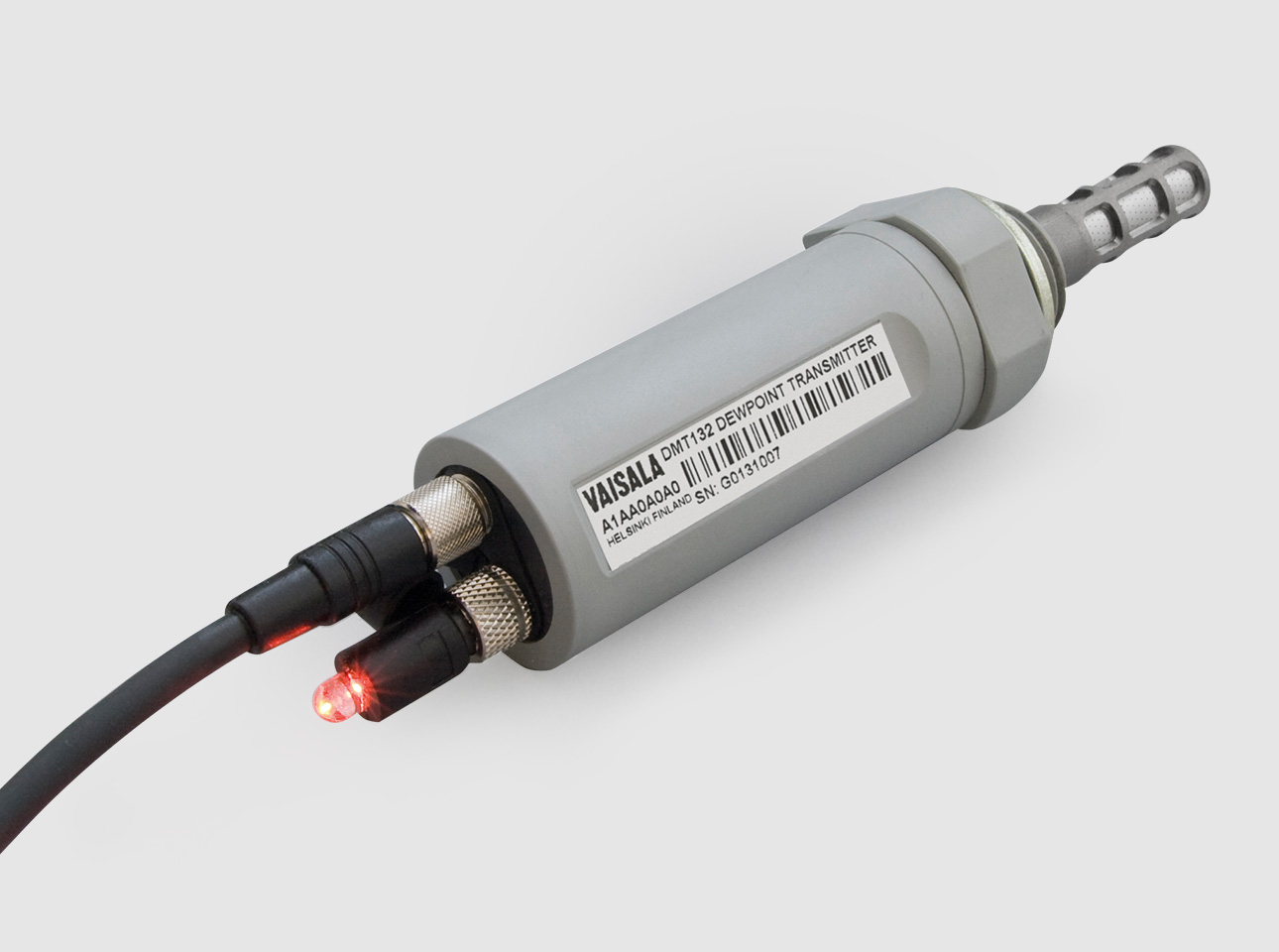

Dew point measurement is the key to optimizing your drying process. Dew point is the temperature where water vapor condenses into dew or frost. When the amount of water vapor increases, condensation occurs when saturation pressure is reached. Air compression increases vapor pressure proportionally and the dew point temperature rises. By installing a small measurement probe in your system you can monitor the dew point temperature and take control of your drying process. Add a hand-held dew point instrument and you will also be able to keep track of the humidity levels in your compressed air lines with regular spot-checks.

Getting started with compressed air moisture control

The first thing to do is to look for a high-quality dew point measurement instrument from a trusted supplier who can serve your needs locally. A high-quality instrument is one that can tolerate moisture well, recover quickly from wet conditions, and provide a fast measurement response time for better process control. The technology behind the instrument is another important consideration. Vaisala dew point sensors, which use patented DRYCAP® technology, are manufactured in our state-of-the-art cleanroom to ensure accurate and stable long-term measurement. We also offer specific options for different dew point temperatures to ensure the best possible accuracy as well as different options for managing your instrument life cycle. We continuously develop our instrumentation ecosystem, which includes several measurement parameters, so that our customers can benefit from modularity and plug-and-play features.

Download our Compressed Air eGuide to save energy when using compressed air

Add new comment