The Ryoki Kogyo Co., Ltd. helps to create optimal living and working environments

Developing infection control measures

The Ryoki Kogyo Co., Ltd. has been around since 1930. Originally a manufacturer of refrigeration equipment, the company's core business today is the installation of air-conditioning and water supply/drainage systems in eastern Japan. Company's mission is to help create optimal living and working environments and contribute to the creation of a more sustainable society. They are especially focused on improvements in public health, safety, and comfort by improving the quality of the air people breathe.

ProOptiment is The Ryoki Kogyo's patented infection risk management system for living spaces. It is designed for public facilities, hospitals, educational institutions, and other locations where large numbers of people gather. By measuring CO₂ concentration, temperature, and humidity along with regional epidemiological data from the Internet, ProOptiment can quantify risk in terms of the likelihood of infection. ProOptiment monitors the atmospheric environment in real-time, automatically controlling air-conditioning/ventilation, air flow, and humidity according to the risk of infection. More details regarding ProOptiment can be found here (note – page is in Japanese)

ProOptiment was created with the medical field in mind. The aim was to reduce the workload of medical practitioners by quantifying the airborne infection risk in hospitals. With the outbreak of COVID-19, it soon became clear that only the most reliable infection prevention measures should be considered acceptable.

Today Ryoki Kogyo's objective is to reduce infection risk not only in the medical field but throughout society as a whole, by targeting public areas where large numbers of people gather. Their expectation is that statistical risk management will become more welcome as the world learns to live with the coronavirus. As this occurs, the infection risk indicators we provide will become more and more important.

What is the benefit of measuring CO₂ concentration for infection risk management?

Automatic control systems can be used to activate ventilator fans when a building becomes crowded. This can reduce the risk of infection in a crowded space. Such control systems have already been broadly adopted throughout Japan, relying on CO₂ concentration measurement as the control variable.

However, problems can occur when CO₂ concentration measurement is used as the sole basis for ventilation control. If community transmission is relatively low, then air-conditioning energy can be wasted due to the unnecessarily large intake of outside air.

It is simply too much to ask health care professionals to weigh the need for energy conservation against the risk of infection. ProOptiment removes the need for manual operation. By tying the operation of ventilators to infection risk rather than solely relying on measuring CO₂ concentration, ProOptiment allows you to control infection risk, reduce your workload, and improve your energy efficiency.

“Our main goals were to remove the burden on users, visualize the risk of infection, take preventive measures based on clear data, and achieve ventilation control linked to these measures”, says Masahiro Renda, Manager at Solutions Development Division, Ryoki Kogyo Co., Ltd.

ProOptiment uses Vaisala’s GMD20 series CO₂ transmitter, GMW80 series CO₂ humidity-temperature transmitters (GMW83DRP, HMS82), and the GMP252 CO₂ probe.

“The measuring instruments used in ProOptiment are modularized to ensure simple installation and replacement. This means that users can expect advantages such as stable supply and flexible after-sales service. We can also handle changes in use on-the-fly.” says Masahiro Renda. “When selecting CO₂ sensors, it’s necessary to carefully consider not only price range but also function and form" he continues. "For example, safety and comfort must also be demonstrated in places where large numbers of people gather, so the displays and range of color variations available have also become important selection criteria.”

Importance of CO₂ concentration measurement for calculating risk of infection

“The most important item when calculating risk of infection is indoor CO₂ concentration. However, it’s also very important to accurately ascertain the degree to which CO₂ concentration has increased by comparing with outdoor CO₂ concentration. Both factors directly affect the calculation and are essential items for the system itself, so we wanted to find CO₂ sensors with the highest precision possible.” says Masahiro Renda.

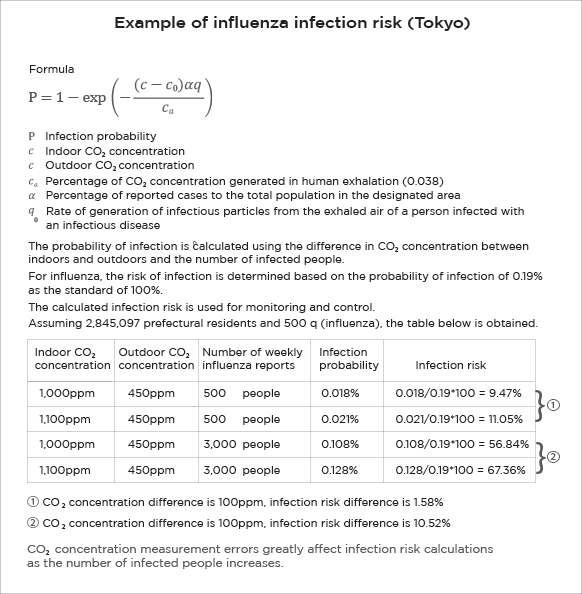

The following trial calculation shows the importance of precision in the data supplied by CO₂ sensors.

The likelihood of infection when indoor CO₂ concentration has changed from 1190ppm to 1290ppm increases by 2% when there are 500 infected persons present. The likelihood of infection increases by 10% when there are 3,000 infected persons. For example, in the case of influenza, the risk of infection of 0.19% will be converted at the alert level of 100% as default, where alerts/controls are performed.

(1) Air purifiers (multiple units installed) (2) UVC equipment (multiple units installed)

Risk of infection is calculated by means of two values: difference in CO2 between outside air and indoor air, and number of infected persons. An increase in the number of infected persons also changes the extent to which CO2 measurement error values are affected, so it is not possible to say how much effect there is across the board.

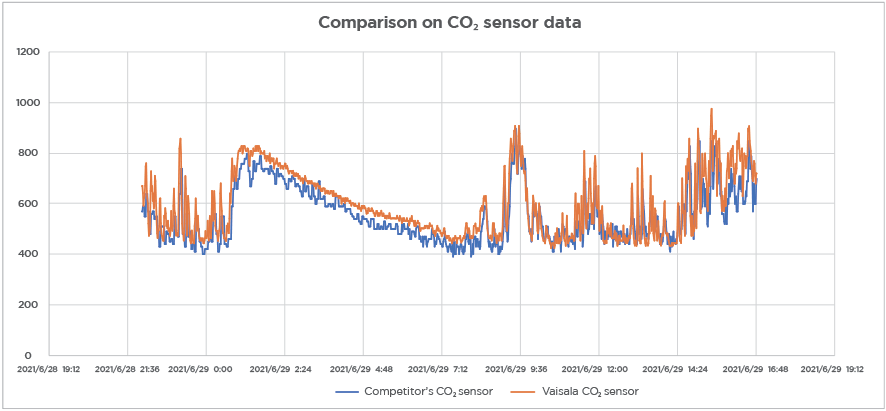

“There are many different CO₂ sensor manufacturers, and there are also devices sold as CO₂ sensors which also measure other gases. We had a bitter experience early on, when we were using another company’s CO₂ sensor that was unreliable and unable to perform calculations properly. We searched high and low for a CO₂ sensor that could provide accurate measurement using the nondispersive infrared (NDIR) method, and finally we arrived at the Vaisala CO₂ sensor, which is extremely high precision. I remember being amazed when I learned that it even has an automatic correction function. What's more, it comes with a 5-year warranty, so we can look forward to enjoying high-precision measurement for a very long time.” - Masahiro Renda

“Furthermore, being able to replace only the sensor when replacing a module is very convenient and provides the user with the major advantage of eliminating the need for maintenance”, Masahiro Renda concludes. Comparative testing was used to help us select a CO₂ sensor for use with ProOptiment. Comparing the CO₂ concentration measurement data clearly shows any differences in sensing precision. on with infection risk to make public spaces safer for everyone.

Patented technology for high-precision CO₂ measurements

Vaisala uses single light source, dual wavelength nondispersive infrared (NDIR) technology for measuring CO₂ concentration. The patented CARBOCAP® technology is used in all of Vaisala’s CO₂ sensors. The Vaisala CO₂ sensor also features an innovative micro-machined, electrically tunable Fabry-Perot Interferometer (FPI) filter. This filter makes it possible to select the wavelength to be measured. Wavelengths absorbed by CO₂ can be selected for measuring CO₂ concentration, and wavelengths not absorbed by CO₂ can be selected for standard measuring. With this filter, any CO₂ concentration measurement error caused by light source deterioration or light path contamination is corrected. This makes it possible to eliminate the causes of general measurement value drift that occur in other manufacturers’ NDIR sensors.

“If you have CO₂ sensors both indoors and outdoors, you can be assured of more accurate calculations. Some users find it difficult to install CO₂ sensors outdoors, but measurement error can occur when measuring only indoors, so we recommend sensing both indoors and outdoors”, says Masahiro Renda, Manager at Solutions Development Division, Ryoki Kogyo Co., Ltd.

Field tests in CO₂ concentration measurement were conducted at multiple medical facilities over a period of more than one year. After application there were no periodic or sudden problems, nor any cases of measurement value drift. At one medical facility, the use of a heat exchange ventilation system reduced the risk of infection by 30% without having a negative impact on air conditioning or heating performance. At the same time, an 87% energy savings was achieved in relation to the increased ventilation.

Using humidity measurement technology to supplement human intuition

ProOptiment also has a built-in function that measures the Predicted Mean Vote (PMV) from temperature and humidity in addition to measuring CO₂ concentration. PMV is an essential indicator in the area of air-conditioning, as it essentially displays heat comfort. Normally, humans are said to be less sensitive to humidity than they are to heat, so many people are unable to connect their discomfort and latent health issues to changes in humidity even if there is in fact a relationship between them. Therefore, human intuition can be supplemented by using humidity measurement technology.

“I think there are also cases where automatic control can help people who are unable to convey the fact that they are feeling discomfort, such as patients in medical facilities. Also, since the calculation methods are different for people who are moving and people who are standing still, parameters can be changed even within the same facility according to different purposes, such as waiting rooms where many people are seated and recreational facilities where people are moving more”, says Yasuo Takano, Leader at Solutions Development Division, Ryoki Kogyo Co., Ltd.

“It is also possible to take preventive measures by configuring installation with stricter standards than the automatic controls, such as for immunodeficient patients who are at high risk from infectious diseases. Visual alerts can also be left as-is while configuring only the controls ahead of time. Control systems can be changed for each pathogen and customized for each facility.”

- Yasuo Takano, Leader at Solutions Development Division, Ryoki Kogyo Co., Ltd.

With flexible configuration options such as these, ProOptiment is very user-friendly. Vaisala provides a wide range of products for measuring CO₂ concentration, temperature, and humidity, including installable sensors for Indoor Air Quality (IAQ) that can measure the three elements in a single unit and high-precision modular CO₂ sensors that can be installed anywhere.

A new concept in automatic control systems

“HVAC is the main focus of our business, so we already had our own concept of IoT using sensors. In recent years, we have had a significant increase in opportunities to use sensing data. Looking ahead, I think there will be many more situations where sensing data is used in all areas of society”, says Masahiro Renda. “We see a future in which remote monitoring [using sensing data] becomes an essential technology for the resolution of social issues such as being carbon neutral, energy conservation, labor shortages, and predictive maintenance”, continues Yasuo Takano.

To achieve efficient, smart management using this kind of system, CO₂ sensors must be selected on the basis of adequate understanding of CO₂ sensor types and characteristics, such as how data is collected by facilities, the best places in a facility to install each type of CO₂ sensor, and how to wire the installation. Vaisala has an extensive lineup of high-precision CO₂ concentration measurement sensors that are easy to install and can be used as system modules.

Among other things, a cutting-edge smart management system should be able to collect facility and operational status data and to implement control remotely. Versatile application including remote operation of unmanned facilities and issuing control orders to factory lighting and air-conditioning systems will lead to even more efficient energy-saving initiatives and the improvement of working environments. Also, the resolution of issues such as public health, labor shortages, environmental measures and security will greatly expand the potential of our social life. Vaisala’s goal is to continue to be a reliable partner for system development companies, jointly developing value for the future. Ryoki Kogyo's ProOptiment infection risk management system achieves this goal by measuring CO₂ concentration in conjunction with infection risk to make public spaces safer for everyone.

Are you interested to know more about Vaisala's HVAC solutions? Read next how Infosys monitors indoor air quality with Vaisala's HVAC sensors or browse our HVAC measurement page to discover more interesting topics.