Case

Easy and accurate validation system ensures competitive advantages to mapping service provider

Since 1988, Performance Validation (PV) has provided validation, commissioning, and quality services to pharmaceutical, biotechnology and medical device manufacturing and distribution. For over 30 years, the company has operated under its mission to provide peace of mind for their clients in life science industries.

PV provides a full suite of Commissioning, Qualification, and Validation (CQV) services, including:

- Validation Master Plan (verification, commissioning, validation, project plan)

- Risk Management as per ISPE guidelines, GAMP5, and ICH Q9

- Requirements and specifications development

- Design and enhanced design review

- Vendor management including audits, assessment, and testing

- Change and configuration management prior to system turnover and acceptance

- Testing: Commissioning and Qualification, Verification, Validation, or other testing activities (FAT/SAT)

- Formal release/turnover activities and system acceptance

- Periodic Review (e.g., annual audit) of the qualified systems

Neil Enlow is a Principal Engineer with Performance Validation and Manager of PV’s temperature mapping service group. Mr. Enlow has worked for PV for almost 20 years and has a background in project management and specialties in equipment, utility, and facility CQV; Temperature Mapping and Steam in Place (SIP) validation.

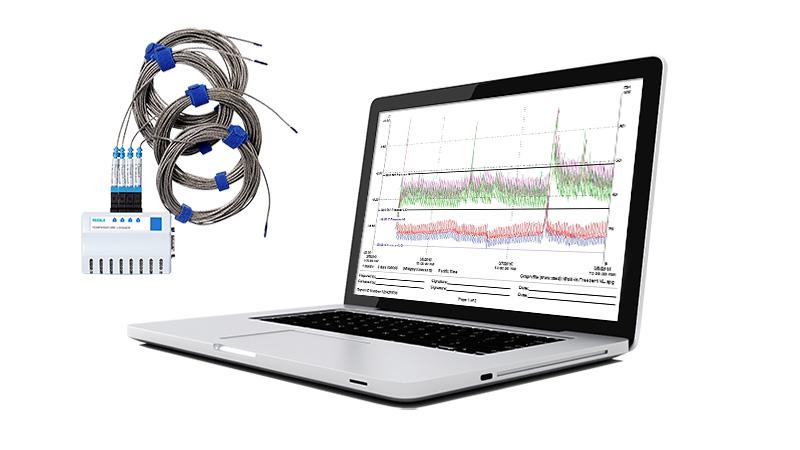

Mr. Enlow recalls that when he began working with PV, the company already preferentially used Vaisala data loggers for thermal validation projects. “We use a lot of the DL1000 temperature and DL2000 temperature and humidity data loggers for controlled temperature storage mapping,” says Mr. Enlow. “For cold temperature validations (e.g. freezers and ultra low freezers) we use the DL1416 data loggers that have four channels, each utilizing 25 ft. external wired probes.”

User-friendly and designed for life science

One of the Vaisala validation system features that has made PV a long-term user is the vLog software that is used to download and analyze the DL-series data loggers. “The vLog software is extremely easy to use,” says Mr. Enlow. “Based on other systems we’ve used in the past, vLog is comparatively user friendly and much simpler than any of the other systems we’ve tried. The batch setup feature is a huge time saver when using a large number of loggers and the graphs and reports are easily configurable to meet our needs.”

The vLog software creates electronic records of temperature, humidity, and other conditions and is 21 CFR part 11 compliant. PV has validated the vLog software and data loggers as a hybrid system, where the graphs and reports are created then printed and signed by users and reviewers to be included as part of the hard copy validation record.

The software allows users to generate secure files and audit trail reports that ensure data logger files maintained electronically have not been altered or modified in any way. The software can output both graphs and tabular reports that are secure and traceable. In vLog, traceability of electronic data is achieved using administrative options (security levels), the Audit Trail report, and data logger File ID Numbers. These features ensure users cannot accidentally use the wrong data logger files in graphs and reports.

Robust, accurate data loggers

Along with user-friendly software, the DL-series loggers are dependable and robust. To reduce cost, PV is able to remotely complete many large warehouse temperature mapping projects where sensors are shipped back and forth all over the country. Validating large environments like warehouses often entails placing data loggers in all sorts of different locations at varying heights, with surrounding warehouse operations in progress. The loggers have held up well to repeated use in these types of environments.

“The vLog system is not the lowest priced system on the market,” says Mr. Enlow. “But if you take into account the life of the sensors, the lifetime system cost is excellent. Certainly, there are the costs of the loggers and annual calibrations, which requires a sizeable up-front investment. But, those costs stretched out over the life of the system are more than reasonable compared to almost any other system we have looked at. The usability of the system and accuracy of the measurements make using the vLog system a no brainer for us.”

Over at least two decades, the features of the vLog validation system and the reliability of the DL-series data loggers has made the system a worthwhile investment. “That’s why we keep buying more,” says Mr. Enlow. “And every time we add more Vaisala data loggers to our inventory, we end up using them. If we look at the system in terms of profitability, they more than pay for themselves.”

Serving pharmaceutical customers’ needs

PV has their DL-series data logger inventory calibrated at Vaisala’s calibration laboratory located in Woburn, Massachusetts. “From the standpoint of measurement accuracy, the Vaisala data loggers are typically better than the other devices we might use, or see other people using in the industry,” says Mr. Enlow. “In all instances, the accuracy of the data loggers meets our clients’ needs. We don’t see many calibration failures.

“We recently had one large pharmaceutical customer who had experienced some issues with a non-Vaisala thermal validation system. The company had concerns with the accuracy of the devices and quality of the calibrations and documentation. They made an internal decision to use only Vaisala data loggers for thermal validation.”

PV maintains a large inventory of Vaisala DL-series data loggers and is a long-term user of the vLog software, so this requirement from the pharmaceutical firm was not difficult to fulfill. “With our extensive Vaisala data logger inventory, we were happy to be in a position to serve their needs, even for larger projects. There are other service providers working with this pharmaceutical firm, so it’s nice to have a competitive advantage in this area,” says Mr. Enlow.

“Over a 12-month period we could typically use a given DL-series logger for at least a dozen different projects for various clients in different locations and applications throughout the country. Depending on the year, we might do up to 20 or more validation projects between annual calibrations. Despite heavy usage, we rarely see temperature sensor failures.”

- Neil Enlow, Performance Validation

PV also offers short-term rental of the vLog system and data loggers for do-it-yourself customers. PV maintains the validation and calibration of the system so customers can supplement an existing inventory of loggers, or use vLog as a stand-alone system quickly and directly from PV. “We have a large inventory of loggers and no experience or training is needed, so most customers can simply follow our SOP for using the vLog system.”