Accurate environmental measurements in microbiology: Neutral Bioassay Co., Ltd. virus clearance process validation

In recent years, a wide range of biological products have been used to create new drugs and therapies. However, the production processes for biological products entail multiple risks, including viral contamination, so it's important to ensure safety and verify effectiveness. An independent third-party testing organization approved by China's Hangzhou Administration for Market Regulation, Neutral Bioassay Co., Ltd., specializes in virus clearance process validation and provides customers with effective validation at multiple stages of product development. Through close collaboration with Vaisala, Neutral Bioassay delivers environmental testing services up to or above industry standards with process validation services to pharmaceutical companies. The company offers process safety and effectiveness validation for virus clearance processes at both the process development and clinical trial stages.

Safeguarding Biopharmaceuticals

With the global increase in biological products and applications, many countries have strict regulatory overview for the safety of biopharmaceuticals, including the Investigational New Drug (IND) application and the Biologic License Application (BLA).

"Before biopharmaceuticals can enter clinical trials and be approved for market, it is necessary to conduct effective validation of virus clearance processes to demonstrate that the production process is capable of retaining and inactivating relevant viruses," said Shen Dejin, the head of Neutral Bioassay. "Neutral Bioassay is an independent third-party organization that provides process effectiveness validation services tailored to the needs of clients in the biopharmaceutical industry. We offer customized validation services for the IND and BLA stages, as well as provide bilingual reports and solutions for both domestic and foreign clients."

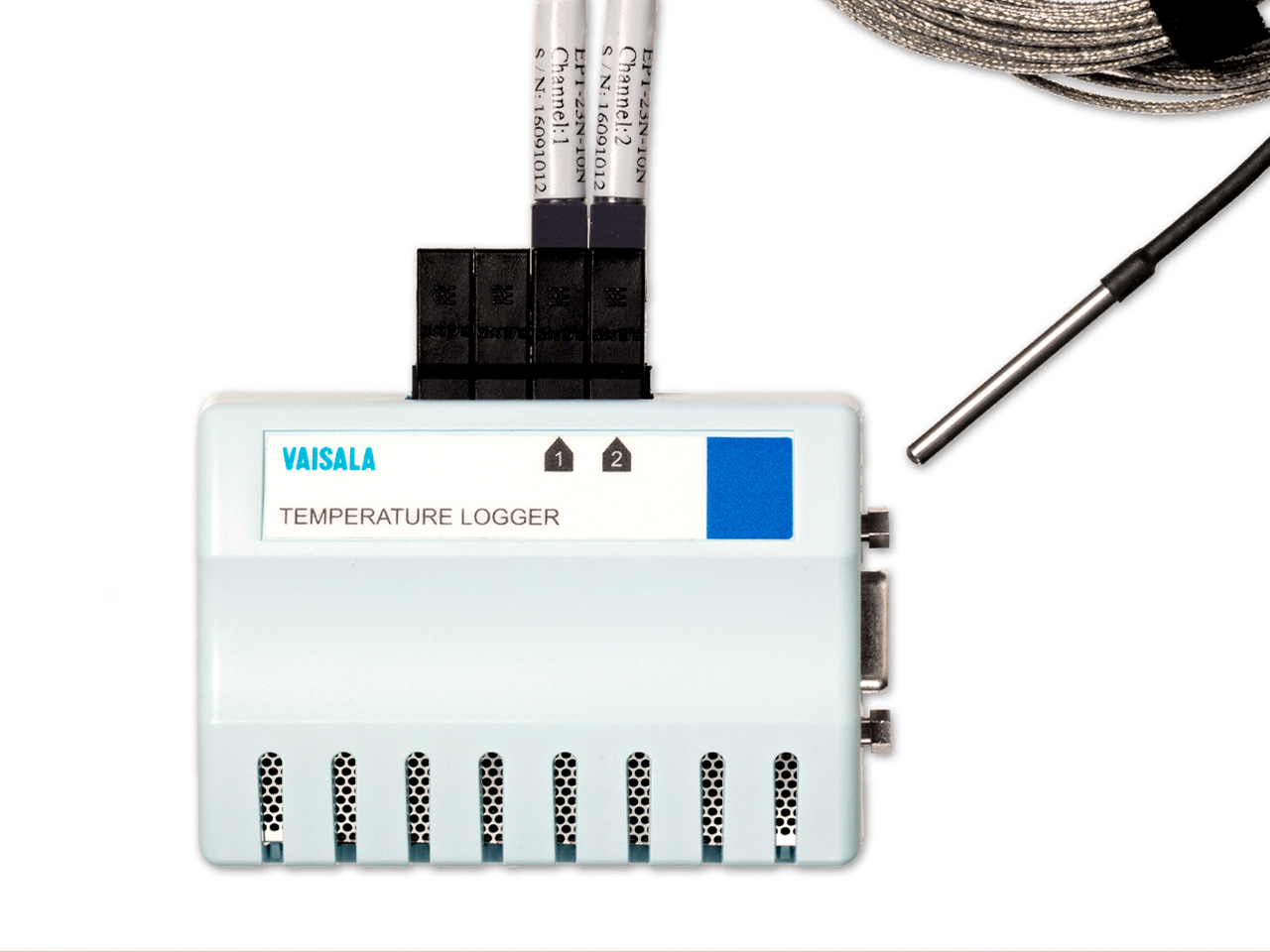

To meet stringent requirements for product safety, Neutral Bioassay helps their customers take preventive measures and ensure the necessary conditions for validation processes. This work helps meet higher industry standards and mitigating risks. In April 2020, Neutral Bioassay invested over 50 million yuan to establish a high-standard BSL-2+ laboratory in accordance with the Architectural and Technical code for Biosafety Laboratories (GB 50346-2004). The new laboratory comprises a cell laboratory, a virus laboratory, a multi-functional laboratory, a molecular biology laboratory, and other functional units. The facility is equipped with more than two hundred internationally validated mainstream testing instruments as well as the Vaisala viewLinc Continuous Monitoring System (CMS), which enables real-time online monitoring of the laboratory environment conditions.

Having obtained certification from CMA (China Metrology Accreditation) and accreditation from CNAS (China National Accreditation Service for Conformity Assessment), Neutral Bioassay can simultaneously support multiple independent validation projects. These accreditations have enabled significant growth for Neutral Bioassay, which has produced revenues of approximately twenty million yuan since 2022.

Integrated Continuous Monitoring for Demanding Environments

The biopharmaceutical industry has many special requirements for safety. As an important service provider in the industry, Neutral Bioassay must maintain high quality standards. For environmental monitoring they choose Vaisala hardware and software because these solutions not only meet industry standards in measurement accuracy, but also go beyond Neutral Bioassay's own high standards.

"We have strict requirements for temperature, humidity, and carbon dioxide measurement accuracy for high testing standards and smooth completion of experiments," said Mr. Shen, who has been impressed with the measurement accuracy of Vaisala products. "Vaisala’s various parameter probes deliver satisfactory accuracy, which is up to and even above various industry standards."

The viewLinc Continuous Monitoring System can be integrated with a wide variety of data loggers, probes, transmitters, and Modbus devices to monitor multiple parameters, such as temperature, relative humidity, carbon dioxide, and differential pressure. When viewLinc is used with Vaisala's intelligent humidity and temperature probe HMP3, the temperature accuracy can be ±0.1°C (0.18°F), and the relative humidity (RH) accuracy 0.8% RH. When the system is used with the carbon dioxide transmitter GMD110, the measurement accuracy can be ±40 ppm (parts per million). Furthermore, with the help of viewLinc, users can easily measure the parameters at thousands of monitoring points, which offers more possibilities for Neutral Bioassay's expansion.

According to Mr. Shen, apart from the high accuracy, data integrity is also one of the main reasons why Neutral Bioassay choose Vaisala. "During two years of use, Vaisala's system performance has been stable and it records data effectively, even in the event of a power outage."

Ease-of-use ensures operational excellence

The viewLinc software takes the practical needs of users into account. The system scales easily, from a single device to thousands. All data and alarm records are automatically stored on the viewLinc system server.

"Vaisala’s products have highly open functionality, and a feature user-friendly interface, easy access to data, and user-centric design," said Mr. Shen.

As the software component of the Vaisala environmental monitoring system, viewLinc provides alarms, real-time trend data, and reports that aid in compliance with GxP regulations. Mr. Shen has worked with other monitoring systems. "Compared with the competitors, Vaisala's products have higher accuracy and sensitivity, lower requirements for power supply and better stability, and do not require manual assistance for logging."

Rapid Response & Service Beyond Expectations

"As early as in 2015, when we were exploring other third-party testing organizations, we heard about Vaisala for the first time and gained some basic knowledge about their products." Five years later, when Shen Dejin's team were establishing their own process validation laboratory, Vaisala was the first choice for a continuous monitoring system. In 2021, Neutral Bioassay finalized their plans for the installation of the viewLinc CMS.

"Regarding professionalism and timeliness, the Vaisala team provided us with service that exceeded expectations and was almost impeccable," said Mr. Shen. "From the initial introduction of their services and device configuration to the subsequent updates on the order status, both parties engaged in effective communication."

Vaisala’s service technicians provided timely assistance and training. During the system expansion stage, Vaisala technicians ensured a smooth and efficient installation and validation process. In the end, Vaisala completed the installation and commissioning in a shorter time than expected.

As biopharmaceutical production processes become increasingly complex, audit requirements are also becoming more stringent. Mr. Shen notes that with increasing regulatory requirements, Neutral Bioassay will continue to depend on Vaisala systems and services. Driven by both technology and industry best practices, both companies will face opportunities together to continue to provide high-quality biopharmaceuticals.