Blog

An in-depth look at Vaisala’s hydrogen peroxide sensor technology

Webinar: humidity measurement in H2O2 bio-decontamination – relative saturation as the key

Join us for a 1-hour training with Vaisala's industry experts Piritta Maunu and Sanna Lehtinen. Piritta and Sanna will cover the key aspects of measuring humidity in Hydrogen Peroxide bio-decontamination. The focus of this webinar will be the crucial role of the Relative Saturation parameter when monitoring vaporized hydrogen peroxide processes.

PEROXCAP measurement values, chemical purge, and function

What is the lowest ppm that the HPP270 series probes can measure?

The measurement range is from 0 to 2000 ppm ±10 ppm or ±5% of the reading (whichever is greater) at 25 °C. The accuracy specifications are stated from 10 ppm onwards. The HPP270 series probes (HPP271 and HPP272) are not intended for safety level ppm measurements.

Does the probe withstand condensation?

The probe must always be powered on when there is H2O2 in the probe’s environment. When powered on, the PEROXCAP sensor is heated, which permits using the probe in condensing H2O2 conditions, maintains measurement performance, and lengthens the probe’s lifetime. If the probe is exposed to H2O2 while powered off, the sensor may dysfunction and not recover. As a worst case scenario, the probe is left for a day under higher temperature, with H2O2 in high concentration, under near condensing conditions, the probe would not survive. Refer to the product specifications for HPP270 series, under “Operating Environments.”

Can the probe measure liquid H2O2?

No, the HPP270 series probes are for vaporized hydrogen peroxide measurement.

Can the probe measure liquid H2O2?

No, the HPP270 series probes are for vaporized hydrogen peroxide measurement.

Does the probe withstand peracetic acid or acetic acid blends?

Vaporized peracetic acid is a very oxidizing agent so the PEROXCAP sensor will not survive in that environment.

Does the probe withstand silver ion blends?

It is not recommended to use the probe with silver ion blends since the silver particles can block the porous filter and therefore deteriorate gas exchange to HUMICAP sensors within the filter.

My customer has H2O2 vapor sterilization under vacuum. Can we use this probe in a vacuum?

The probe is not designed to be used in vacuum conditions.

Can I use this probe in over / under pressure?

The probe is designed for normal atmospheric pressure only.

Are Relative Humidity and Relative Saturation measured directly from the sensor?

Relative Humidity is directly measured and Relative Saturation is calculated. (Learn more about these values in this webinar.)

Relative Humidity is directly measured and Relative Saturation is calculated. (Learn more about these values in this webinar.)

Which parameters does the HPP271 and HPP272 output?

The HPP272 outputs H2O2 concentration (ppm), temperature and humidity (Relative Saturation and Relative Humidity); The HPP271 outputs H2O2 ppm by volume and H2O ppm by volume.

The HPP272 outputs H2O2 concentration (ppm), temperature and humidity (Relative Saturation and Relative Humidity); The HPP271 outputs H2O2 ppm by volume and H2O ppm by volume.

Why is the absolute hydrogen peroxide unit in mg/m³ and not mg/L?

We have chosen the International System of Units (SI) mg/m3 , whereas mg/L is not an SI unit.

How do I convert mg/L to mg/m³

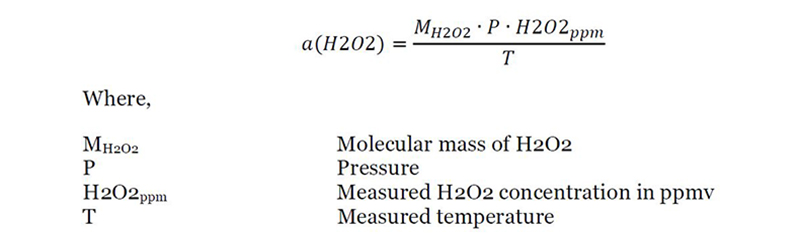

Absolute H2O2 mg/m3 (milligrams per cubic meter) can be converted into mg/L (milligrams per liter) by using this formula:

Absolute H2O2 mg/m3 (milligrams per cubic meter) can be converted into mg/L (milligrams per liter) by using this formula:

Why does the HPP271 only output H2O2 ppm and not Relative Humidity and Relative Saturation?

The HPP271 sensor contains a PEROXCAP sensor with two composite HUMICAP sensors. The PEROXCAP sensor is warmed in order to provide stable, accurate and repeatable measurement in highly condensing environments. Both Relative Humidity and Relative Saturation are temperature-dependent parameters. Because the sensor is warmed, you need to have an additional temperature sensor if you require an accurate temperature measurement. HPP271 does not have this additional temperature sensor.

The HPP271 sensor contains a PEROXCAP sensor with two composite HUMICAP sensors. The PEROXCAP sensor is warmed in order to provide stable, accurate and repeatable measurement in highly condensing environments. Both Relative Humidity and Relative Saturation are temperature-dependent parameters. Because the sensor is warmed, you need to have an additional temperature sensor if you require an accurate temperature measurement. HPP271 does not have this additional temperature sensor.

How is the HPP272 ppm H2O calculated - on a “wet” or “dry” basis?

H2O ppm is calculated on a “wet” basis.

H2O ppm is calculated on a “wet” basis.

What kind of heating functions does the sensor have?

When powered on, the PEROXCAP sensor is heated (i.e. only the sensor chip under the filter cap is heated, not the probe itself). This prevents condensation from forming on the sensor and provides reliable measurement even in environments where humidity is near saturation. Heating also helps to maintain measurement performance and lengthens the probe's lifetime. The chemical purge heats the sensor at certain intervals. Heating results in rapid evaporation of the chemical contaminants that have been absorbed into the polymer. Chemical purge thus cleans the sensor internally, improving its stability and accuracy. More on this function below...

Which parameters are shown on the Indigo200 series displays when the HPP272 probe is connected?

The display will always default to H2O2 ppm, Relative Saturation and Temperature. The Indigo201’s analog outputs 1 and 2 follow the HPP272 analog outputs when first connected to Indigo201. After that, the user may change the analog outputs and display settings. These will remain even if you detach the probe and reconnect it. Note, only the Temperature value is displayed for the first 8.5 minutes during start-up.

The display will always default to H2O2 ppm, Relative Saturation and Temperature. The Indigo201’s analog outputs 1 and 2 follow the HPP272 analog outputs when first connected to Indigo201. After that, the user may change the analog outputs and display settings. These will remain even if you detach the probe and reconnect it. Note, only the Temperature value is displayed for the first 8.5 minutes during start-up.

What is a Chemical Purge?

The sensor is rapidly heated during chemical purge by forcing a current through the temperature element of the sensor. This rapid heating results in evaporation of chemical contaminants that may have been absorbed into the polymer. Chemical purge thus cleans the sensor, improving its stability and accuracy. A chemical purge cycle takes a few minutes to complete, including heating and equilibrating stages. When the sensor temperature has re-stabilized to the condition prior to the purge, the sensor continues in its normal measurement mode. The value output of the transmitter is locked during chemical purge.

When does chemical purge occur?

The purge (interval purge) is automatically performed at probe start-up and set intervals. The default chemical purge interval is 24 hours, or configurable between 1 hour to 1 week using Vaisala Insight software, Modbus, or Indigo200 transmitters. However, the chemical purge is postponed by 30 minutes if H2O2 is present or Relative Humidity is unstable.

The purge (interval purge) is automatically performed at probe start-up and set intervals. The default chemical purge interval is 24 hours, or configurable between 1 hour to 1 week using Vaisala Insight software, Modbus, or Indigo200 transmitters. However, the chemical purge is postponed by 30 minutes if H2O2 is present or Relative Humidity is unstable.

You can also trigger a purge manually with Modbus (in digital mode) or pin #5 on the M12 connector (in analog mode). The interval purge is postponed by its set value every time you trigger the purge.

Can I disable the chemical purge at start-up or during the bio-decontamination cycle?

No, the chemical purge is essential for the long-term performance and accuracy of the probe in demanding H2O2 environments. Chemical purge is needed at probe start-up to maintain sensor stability. During the purge, H2O2 and H2O measurements are not available.

No, the chemical purge is essential for the long-term performance and accuracy of the probe in demanding H2O2 environments. Chemical purge is needed at probe start-up to maintain sensor stability. During the purge, H2O2 and H2O measurements are not available.

How often is chemical purge recommended?

It is not the frequency of purge processes that is important, but how long the probe is within an environment with H2O2 present. Purge is recommended at least every 24 hours of powered-on time, even if the probe has not been continuously exposed to H2O2. If triggered purge is used, we recommend to implement the purge just before the bio-decontamination cycle.

Note, that it takes approximately 9 minutes to return to accurate readings after a purge. The maximum interval is weekly. Chemical purge is needed to maintain the stability of the measurement and if chemical purge is not performed, the measurement will drift.

Which measurement is available during a chemical purge?

During the purge, only temperature measurement is available (HPP272). During interval and manually triggered purges, the value output is frozen to show the last measured value before the purge began.

Can I do an on-site calibration and adjustment?

You can calibrate and adjust the probe directly in H2O2 vapor with Insight PC software (Insight 1.0.1.107 onwards). Note that calibration in H2O2 vapor is a highly advanced procedure that can be performed reliably only by using another Vaisala HPP270 series probe as a reference instrument and successfully creating matching measurement conditions for both the reference probe and the probe that is being adjusted.You can perform an on-site calibration and adjustment with any RH calibrator, for example: HMK15, or with Insight PC software (Insight 1.0.1.107 onwards).

How can we adjust H2O2 measurement with RH?

The PEROXCAP sensor comprises two HUMICAP humidity sensors that are used to calculate the H2O2 measurement. Because the H2O2 measurement is based on humidity calculations, you can use humidity references to adjust the underlying humidity measurement. Improving the accuracy of the underlying humidity measurement also improves the accuracy of the derived H2O2 measurement.

Add new comment