The recharging economy is here

How environmental test chambers from Guangdong LIK Industry, supported by Vaisala’s sensors, are transforming battery manufacturing

Globally, battery manufacturing is surging, creating demand for a range of related technologies, including high-quality environmental test chambers.

Industrial scale battery manufacturing is done in almost cleanroom-level environments where ambient conditions must be consistently stable and under control, with an ultra-low humidity environment maintained for safety, yield, and efficiency. Humidity control extends throughout the manufacturing chain, and with the ever-increasing complexity and scale of industrial production, the failure of just one component due to environmental factors related to temperature or humidity may cause an entire production system to malfunction. For this reason, many high-precision industrial products must undergo increasingly strict and detailed environmental adaptability tests before entering the market.

In response to this rapidly growing need, Guangdong LIK Industry has developed a range of environmental test chambers for battery manufacturing that rely on Vaisala’s high-precision sensors. These test chambers are already being used by China’s national inspection center as well as by large enterprises both within China and internationally.

General Manager of Guangdong LIK Industry, Dr. Wang Jiangang, explains, “The environmental adaptability of high-precision products is increasingly important from an efficiency and cost perspective. Currently, our test chambers mainly serve three sectors: new energy vehicles, battery protection circuit boards (PCBs), and academic research environmental test equipment.”

More accurate testing is key to future success

With the rapid advance of electric vehicle technology, the need for testing the environmental adaptability of various vehicle components such as batteries has also increased quickly. In particular, both temperature and humidity have a significant impact on the deterioration of an automotive part, which means that accurately predicting how their performance is affected by these variables is especially important. Dr. Wang points out, “Currently, our competitors can only provide measurement chambers with a temperature range from -80℃ to +200℃. Thanks to our joint efforts with Vaisala we can provide accurate temperature control from -250℃ to +200℃, and this wider range solves major challenges related to refrigerant carbonization, insulation layers, and controlling linear logic.”

Regarding the future development of test chambers, Dr. Wang believes they will gradually evolve toward unmanned operation, as well as toward increased miniaturization and energy conservation.

While many of their competitors still use energy-consuming hot and cold hedging for temperature regulation, Guangdong LIK Industry has made several advances that support energy conservation. For example, when heating, their solution is to set the refrigeration module to zero output, and when cooling, they stop the heating module directly.

Dr. Wang explains, “This method of saving energy, seems simple, yet we required the support of Vaisala’s high-precision measurement products to collect accurate temperature and humidity readings. The higher precision the collected signal has, the less fluctuation there is of the data – and the more stable the controlled output is. The result is lower energy consumption.”

Changing the world – together with Vaisala

Since the start of their cooperation in 2013, Guangdong LIK Industry has built a close and highly beneficial relationship with Vaisala. As Dr. Wang explains, “During these past 15 years we have had consistently clear and focused communication and cooperation with Vaisala regarding both product application and technology innovation.”

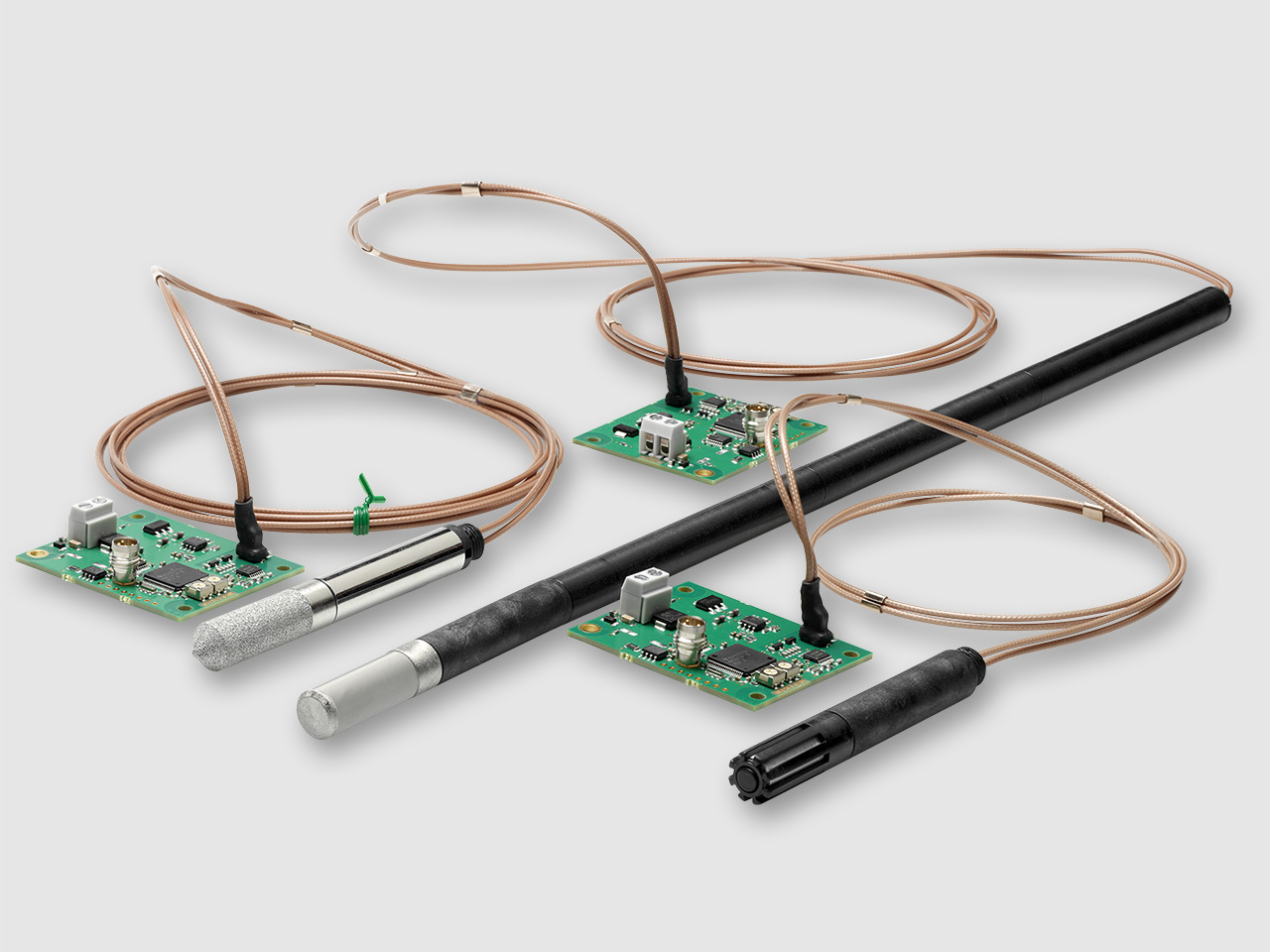

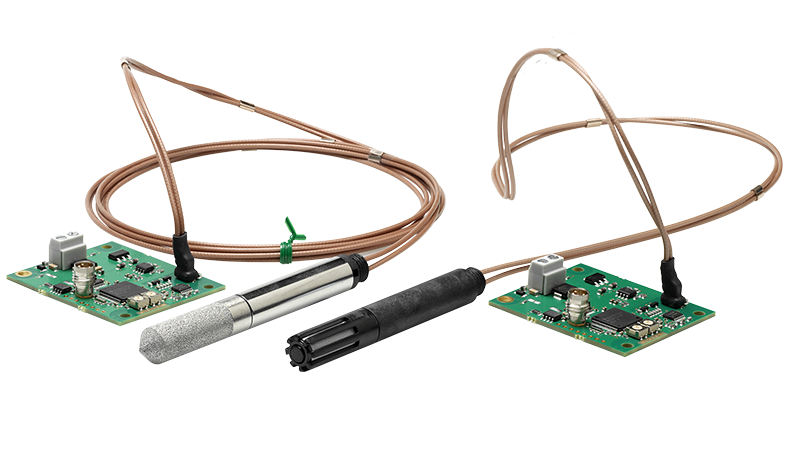

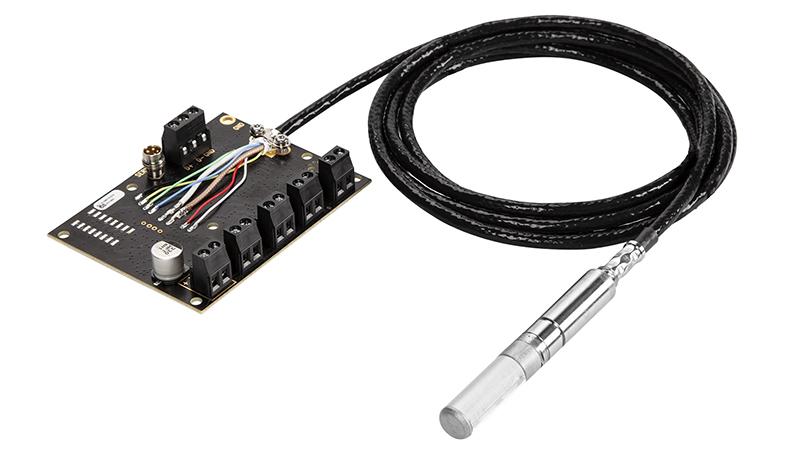

Guangdong LIK Industry primarily uses two Vaisala products in its test chambers. The Vaisala HMM100 is an open architecture humidity module that can be integrated into their test chamber and is equipped with Vaisala's HUMICAP® 180R sensors, which deliver ideal measurement accuracy. The HMM100 requires very little maintenance, and is easy to install and calibrate.

Vaisala’s HMM170 temperature and humidity module is especially well-suited for Guangdong LIK Industry’s test chamber for products that are resistant to harsh environments. It has a higher humidity tolerance and a wider temperature measurement range, and is capable of accurately measuring and outputting parameters across multiple dimensions. Equipped with a Vaisala HUMICAP R2 sensor that provides greater corrosion resistance. It can be used in vacuum environments and pressurized chambers, and can even measure water levels in oil.

As producers increasingly demand greater accuracy and usability, there will be more and more customers eager to update their measurement equipment. As Dr. Wang insightfully puts it, “Together with Vaisala, our common target and mission is to change the world with innovation, and improve quality through the focused application of better technology.”