How a world-leading sulfuric acid producer ensures product quality with Vaisala’s liquid concentration measurement technology

The client: Boliden

Vaisala technology: inline process refractometer

The challenge: to ensure high-grade sulfuric acid production at precise concentrations

Boliden is one of the world’s leading producers of sulfuric acid (H2SO4), manufacturing around 1.7 million tons of high-quality product every year across four sites: Rönnskär in Sweden, Harjavalta and Kokkola in Finland, and Odda in Norway. The highly corrosive, colorless acid is a byproduct of zinc manufacturing and is used in the production of fertilizers and chemicals as well as by the pulp and paper and mining industries. It is typically delivered to customers in commercial concentrations of between 93% and 98%. To achieve the precise concentrations required by different customers, Boliden dilutes pure sulfuric acid with water. To maintain high product quality for its customers, the company uses Vaisala’s reliable and accurate concentration measurement technology to control the acid dilution process.

The solution: robust and accurate inline measurement technology

During dilution, accurate concentration measurement is critical. The corrosive nature of the acid adds a further challenge for the chosen technology. Boliden relies on Vaisala’s highly robust process refractometer technology, which offers three key advantages for chemical production processes:

• it can tolerate highly corrosive conditions

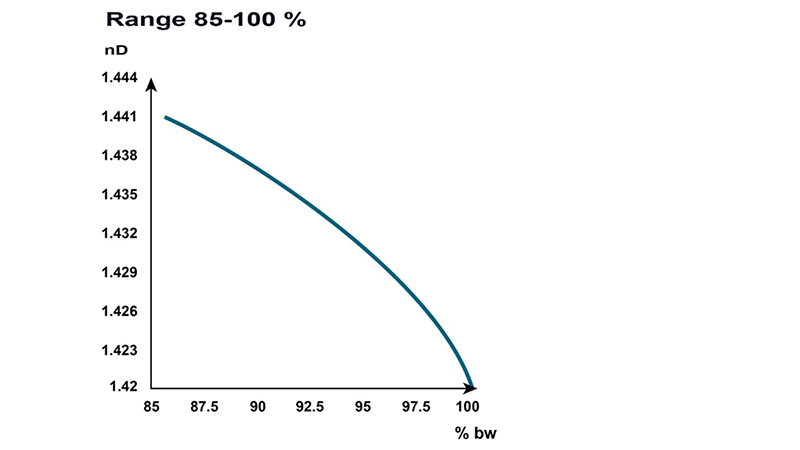

• it provides stable liquid concentration measurement across a wide measurement range (see the graph below)

• measurement accuracy is not affected by air bubbles, color, or changes in the flow rate of the solution being monitored

The Vaisala process refractometer provides more accurate and reliable sulfuric acid concentration measurement in the 85–100% range compared to a density meter. The density curve flattens out after 94%, meaning measurements at concentrations of 95% and above are not possible with a density meter.

Improved storage and transportation

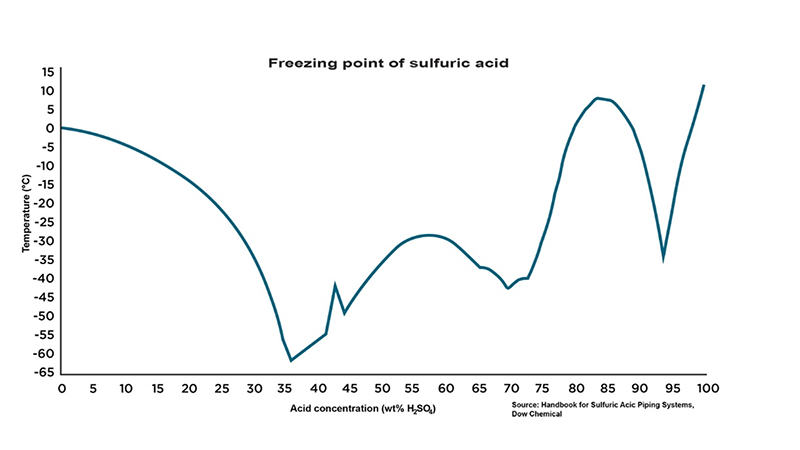

Dilution is also used to decrease the freezing point of the high-quality sulfuric acid produced by Boliden in order to make storage and transportation easier.

For example, the freezing point of highly concentrated (98%) sulfuric acid is +3 °C/ 37.4 °F. Diluting the acid down to 93–96% by weight reduces the freezing point to -20 °C/ -4 °F, making storing and transportation easier particularly in winter conditions. The figure below illustrates why it’s important to verify the exact concentration of the diluted sulfuric acid: once the acid concentration falls below 93%, the freezing point increases.

How dilution works

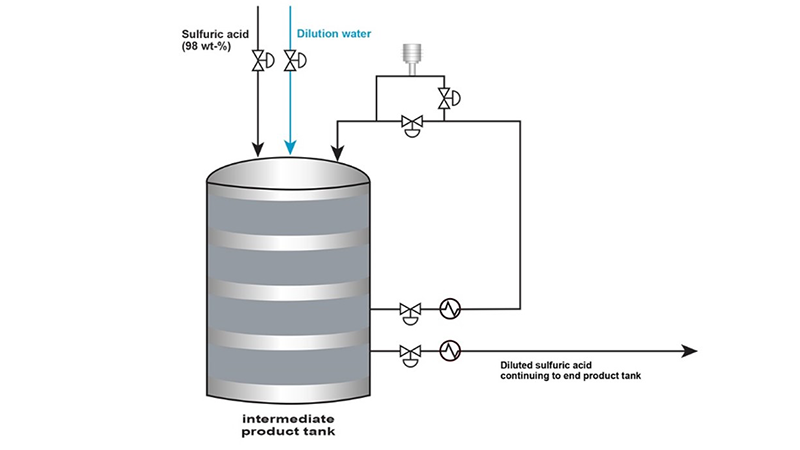

The concentrated acid and dilution water are pumped into an intermediate product tank which includes a circulation loop. The in-line Vaisala process refractometer installed in the loop accurately monitors the concentration of the solution to ensure the appropriate dilution level.

Figure: Sulfuric acid dilution process with Vaisala process refractometer installed in circulation loop. Dilution is a batch process.

Customized measurement solution developed through expert collaboration

The measurement solution for Boliden was delivered by Kontram, Vaisala’s distributor for in-line refractometers in Finland. The company specializes in automation and measurement solutions and provides application expertise and customer support to a variety of industrial customers with the support of the Vaisala process refractometer team.

To learn more about Vaisala process refractometer solutions for your specific application, visit the process refractometer page. To discuss your measurement needs, find your local Vaisala contact on our website or send us a contact request and one of our experts will get back to you.