Real-time chemical identification and interface detection in loading and unloading operations

How to perform custody transfer accurately and reliably?

In loading and discharge of chemicals, it is important to eliminate product transmix, ensure safe handling of multiple chemicals, and reduce the costly waiting time associated with the product transfer to receiving tanks. Chemical industry products are mainly used by other industries, such as semiconductor and pharma industries, which have strict quality and purity specifications. How chemical plants and petroleum refineries can optimize these operations and deliver the highest quality chemicals using Refractive Index technology?

In this blog, we analyze three customer cases and review how the customers were able to benefit from the technology.

The importance of chemical analysis for reliable custody transfer

Chemical analysis is essential for companies that deal with liquid chemicals production and logistics operations, such as chemical plants, petroleum refineries, and fuel terminals to name a few. They need to ensure cost-efficient production of basic, commodity, fine, and specialty chemicals while safeguarding high product quality and minimal environmental impact.

Product identification often relies on manual sampling and laboratory analysis. This method can however lead to time delays, product quality variations, and product waste. Another deployed method is density measurement. When handling such chemicals as acids (acetic, citric, hydrochloric HCl, nitric HNO3, sulphuric H2SO4, etc.), alcohols, glycols, hydrogen peroxide H2O2, sodium hydroxide NaOH (caustic soda), solvents, and urea, density measurement often fails to deliver accurate measurement, requires repeatable recalibration and so appears to be expensive and unreliable.

In-line process refractometer with the accuracy of nD +/- 0.0002 and automatic temperature compensation enables fully automated product identification. Real-time chemical identification and interface detection are required to safely handle the unloading of multiple liquid bulk chemicals from trucks, rail, or cargo supply lines to receiving tanks. Due to real-time identification, one can eliminate human error, improve process safety and reduce costly waiting time.

How the leading chemicals producers and oil refineries benefit from the Refractive Index measurement

Each chemical has a distinctive Refractive Index (nD) value. The in-line process refractometer identifies the chemicals based on their fingerprint repeatably, accurately, and continuously. Discover more from the brochure.

Chemical interface detection for quick handling of multiple chemicals

“By replacing the laboratory measurement with the in-line refractometer for product interface detection,

we were able to save 600 ton of product annually”, - customer.

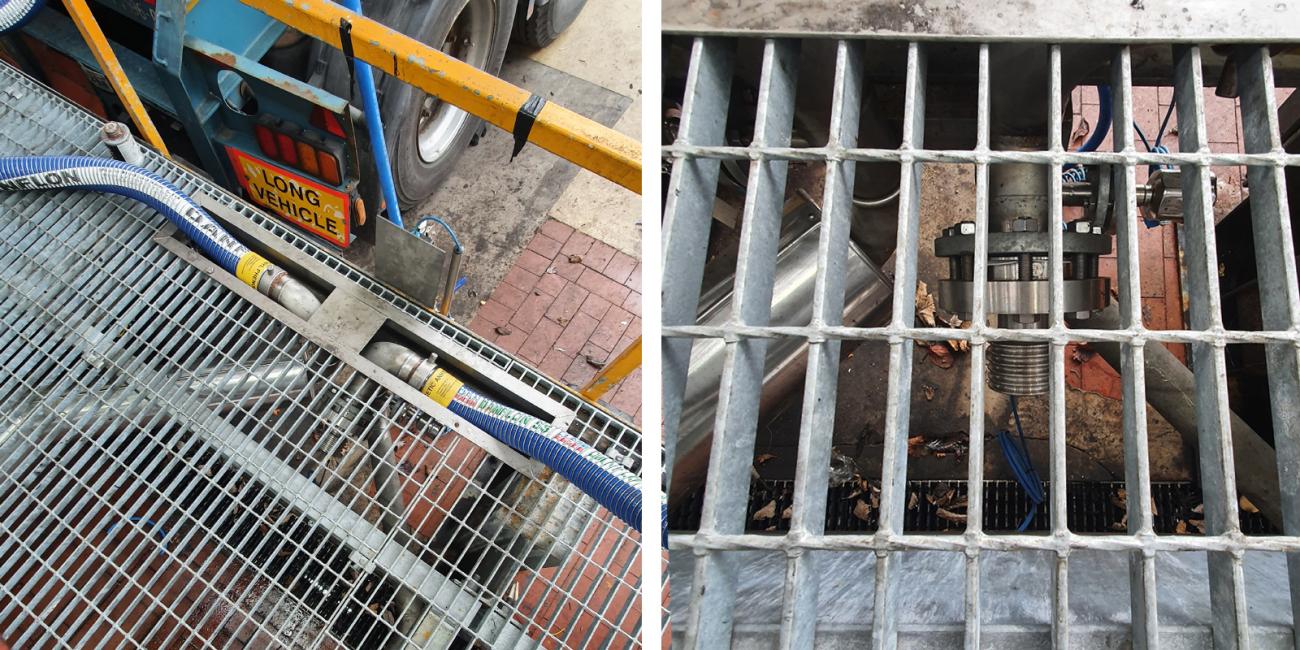

A German multinational chemical company receives multiple chemicals as raw materials for production in its plants. When different chemicals are loaded and discharged from trucks or rail cars to storage tanks at multiple unloading stations, fast and reliable interface detection is necessary for custody transfer, product identification, and safe unloading operation.

The customer’s target was to replace the laborious and unreliable laboratory sampling for four unloading lines with automated chemical control which bases on in-line measurement. They utilized Vaisala’s process refractometer to streamline the loading and unloading operations.

The refractometer provides temperature compensated output and can be set in customer’s preferred scale, e.g. refractive index nD at 20 °C, concentration %-bw or other. With the easy installation of the refractometer in the process line, the customer was able to improve the efficiency of its unloading operations and ensure that the correct chemical within specifications is stored in the right tank.

Ethanol detection in water

A large UK-based petroleum refiner and producer of renewable fuels use storage tanks for various products, for example, ethanol. A process requirement was to detect ethanol in rainwater to determine environmental acceptance before the water was discharged to the watercourse.

At the fuel terminal around the storage tanks, a sump collects rainwater and chemicals in case of leakage. In the existing ethanol storage installation, the currently used density meters had caused false alarms. Also, due to unreliable density meter measurement, the refiner suspected that there may have been possible suspended solids in the surface water.

For two new ethanol storage tanks the customer installed Vaisala’s in-line process refractometer. False alarms have been avoided since refractometers were installed before pumping away rainwater, also ensuring a reliable measurement for regulatory compliance.

Chemical identification at filling line by lubricants producer

“Already during the first weeks after installing the refractometer in the filling line,

we achieved savings by decreasing product waste by 30%", - customer.

A Swiss oil blending and manufacturing company produce a different kind of special oils and lubricants for various industries and applications worldwide. In order to increase production and reduce product waste, the customer decided to raise the level of automation in the filling line. They were using manual sampling and laboratory refractometers to detect interfaces between different products, which is time-consuming and requires manpower, causing also human errors they wanted to minimize.

Once Vaisala’s in-line process refractometer was installed in the filling line to replace laborious manual sampling and laboratory analysis, the customer was reporting considerable savings in the wasted product already during the first weeks. In addition to an immediate return on investment, product quality variations due to laboratory sampling were eliminated and product specifications could be assured.

Vaisala Polaris™ Process Refractometer: the most reliable and accurate watchdog for chemicals

Vaisala’s process refractometer is a perfect match for various industrial applications, in particular, for the chemical industry’s needs because

- its liquid concentration measurement is accurate on a full measurement range of nD = 1.3200...1.5300 corresponding to 0-100 % by weight

- it requires no regular maintenance or recalibration

- it allows for horizontal or vertical installation without by-pass arrangements.

The in-line refractometer measurement of the true dissolved solids is not influenced by undissolved solids or bubbles in the liquid. The refractometer has increased safety and intrinsically safe certification. Special wetted parts to fit demanding chemical processes are available.

Download the application note on chemical interface detection and product identification process to learn the details.