Chemicals & Allied Products

Measuring liquid concentration or density in-line is important in the chemical industry as density variations have impact on both raw materials and finished products. Process safety is also mandatory, since hazardous chemicals represent a potential risk to people and the environment. While managing these challenges, chemical manufacturers strive to produce high-quality products that meet customers’ specifications. To achieve these goals, accurate process measurements, high process efficiency, low energy consumption, and state-of-the-art process control management are crucial.

In-line measurement of liquid concentration and density directly in chemical process

Vaisala Polaris process refractometer is designed to measure and indicate inline liquid concentration of almost any chemical or compound.

The refractometer can be installed cost-efficiently in the main processing line, bypass line or vessel to control the raw and in-process materials in order to extract their maximum value and achieve high quality end products. The performance of all types of chemical refining, manufacturing, and quality-control operations can be dramatically improved with Vaisala’s refractive index measurement technology – whether they are in continuous or batch processes.

Unlike intermittent sampling, continuous monitoring provides instant feedback on changes in the process, and this data can enable real-time and precise process control of the common chemical industry operations, e.g.

- Reactor, reaction degree, and endpoint determination

- Evaporation

- Dissolving tank or vessel

- Dilution, mixing or blending

- Solid-liquid extraction

- Absorbers and wet scrubbers

- Ion exchangers

- Distillation

- Interface detection and product identification of product-to-product interfaces in loading/ unloading

- Quality control

Using the Vaisala concentration measurement technique and its easy integration into plant engineering systems enables significant improvements in the plant capacity, the process safety or product yields.

All you need to know about liquid concentration and density measurements

In this eBook we review two most widely used methods of liquid concentration measurement, i.e. refractive index technology (refractometer) and density (Coriolis, ultrasonic, nuclear, and microwave).

Learn about the advantages and disadvantages of each technology.

Refractive index technique designed for harsh chemical environments and applications

Vaisala Polaris process refractometer offers accuracy, repeatability and reliability even in the most extreme environments that can be corrosive or abrasive, subject to chemically aggressive solutions, extreme temperatures, pressures, vibration or contamination, humidity and dust, or any combinations of these factors. It comes with Ex-certified product versions for hazardous areas.

- Designed to Pressure Equipment Directive PED 97/23/EC and ASME Section VIII Division 1 - Pressure Vessels

- Selection of different IP codes (IEC 60529) and NEMA ratings that withstand various harsh conditions and outside use.

- Special wetted parts materials ranging from stainless steel and higher alloys to PFCF or PTFE (Teflon®) for harsh environments and chemically aggressive process fluids.

- Intrinsically safe and hazardous area certification for hazardous areas

Webinar - Liquid Measurements in demanding chemical applications: Density Vs. Concentration

Density or refractive index, which measurement technology is right for your chemical process?

Bubbles, particles, scaling, and corrosion can compromise your concentration measurements. In this webinar you'll learn how to choose the best inline measurement technology for demanding chemical applications and why it matters for safety, quality, and efficiency.

Vaisala capabilities and services for the chemical industry applications

Vaisala is specialized in in-line process refractometers and optical process analyzers for refractive index-based concentration measurements. Vaisala instruments range from compact probe models for small pipeline and bypass lines to rugged heavy-duty long probe versions for large pipeline, vessel and reactor installations. When standard models are not sufficient to fulfil requirements, please consult the factory for engineered solutions, e.g. special wetted materials or custom mounting accessories and process connections.

Vaisala also provides full range of start-up, commissioning and technical support services to our customers. Our industry expertise includes supply of extensive vendor documentation that is tailored and applied to each contract and client specific data. Local authorized distributors have extensive applications knowledge and they can help to specify the correct instrument for each application requirements.

All you need to know about in-line liquid concentration and density measurement

Processing industries use liquid concentration or density as a key parameter for controlling and adjusting the process to ensure the desired output. This can be done using the refractometer technology or density meters. What are the operational and economic benefits of both techniques? This and other aspects on how to choose the right measurement technology for the most demanding processing applications will be discussed in the webinar.

Applications in the chemical industry

Bulk and Fine Chemicals

More Bulk and Fine Chemicals

Chlor-Alkali Products

Polymers and Plastics

More Polymers and Plastics

Fertilizers and Explosives

Other Chemical and Allied Products

Effluents Treatment

Loading and Unloading Operations

Applications in the fiber and textile industries

Regenerated Cellulose Fibers

- The Lyocell Process (If you would like to receive the complete application note, please contact Vaisala).

- Cellulose Acetate Fiber Production

Synthetic Fibers

Textile Wet Processing

Liquid concentration measurement in chemical and textile fibers

This eBook can be interesting for chemical and textile fiber fabricators and processors. It provides insights on the most common fiber and textile processes, and explains the role of in-line instrumentation for automatic and precise control of raw materials and solvents in these processes. The process optimization benefits include but are not limited to energy and material savings. Discover more by downloading the eBook.

Applications in biofuels

Bioethanol Process

Biodiesel Process

Applications in other industries & operations

Automotive

Metalworking and Machining

Metal Mining and Refining

Elastomer and Polymer Products

Learning resources

Unlocking Efficiency: Refractive Index Insights for Chemical Industry

In this webinar Vaisala's Kevin Green is joined by Dave Lobach of Rocky Mountain Instrumentation, Inc. (RMI).

Learning agenda:

- How refractive index can optimize multiple chemical processes with accurate and low maintenance measurement

- Real-world applications in diverse industries, from oil refining to wastewater treatment

- Smart quality control, lower energy consumption, reduced waste, and enhanced efficiency

Mastering Sulfuric Acid Measurement: Successes in Oil & Gas Refinery Operations

In this webinar Vaisala's Regional Sales Manager Kevin Green welcomes two key players from the refining industry. Grant Ruediger and Cody Jensen of Elessent Clean Technologies describe how liquid measurement technology for sulfuric acid is helping to produce cleaner burning fuels, while saving costs and safeguarding refining operations.

Learning Agenda:

- Discover Alkylation Technology that utilizes sulfuric acid to convert low-value olefins to produce clean gasoline with superior blending properties.

- Explore various methods for measuring sulfuric acid, including inline refractometers, Coriolis meters, and titration sampling.

- Hear about successful industry use cases from the experts who implement and maintain these systems.

How a world-leading sulfuric acid producer ensures product quality with liquid concentration measurement

Boliden is one of the world’s leading producers of sulfuric acid (H2SO4), manufacturing around 1.7 million tons of high-quality product every year across four sites: Rönnskär in Sweden, Harjavalta and Kokkola in Finland, and Odda in Norway. The highly corrosive, colorless acid is a byproduct of zinc manufacturing and is used in the production of fertilizers and chemicals as well as by the pulp and paper and mining industries.

Chemicals & Allied Products related products

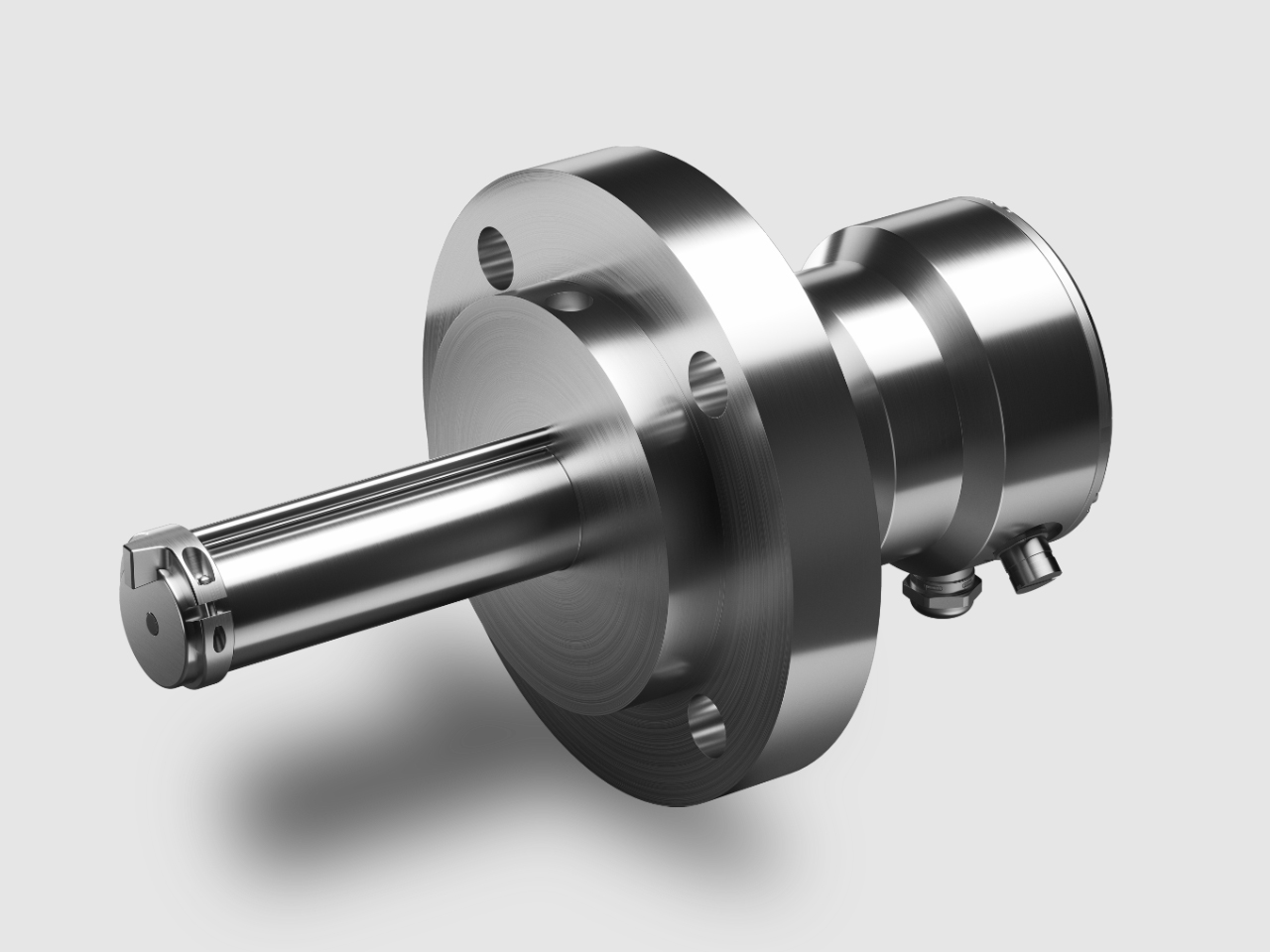

Vaisala Polaris™ PR53GP and GPEX Probe Process Refractometers for ordinary and explosive areas

Vaisala Polaris™ PR53GC and GCEX Compact Process Refractometers for ordinary and explosive areas

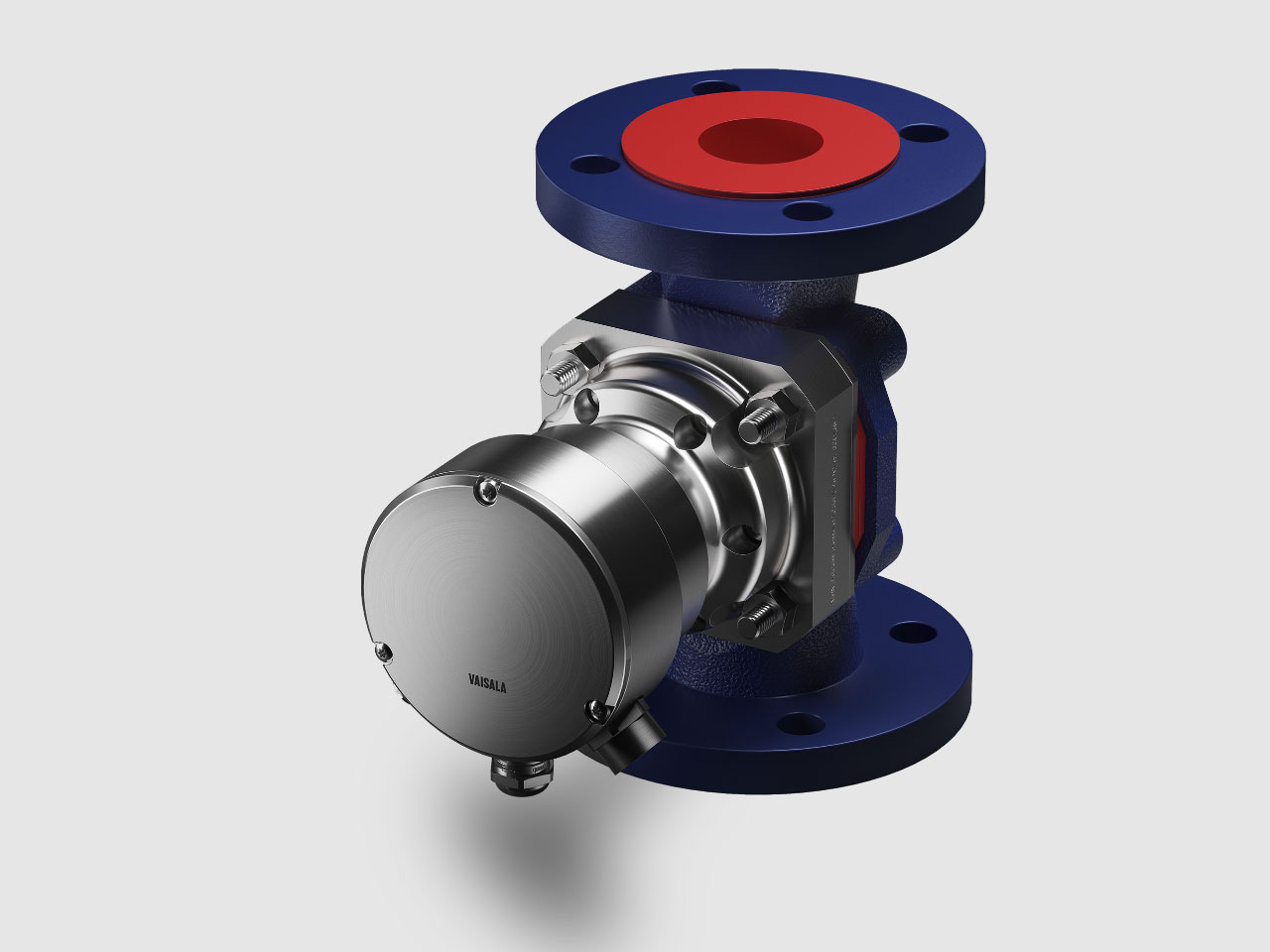

Vaisala Polaris™ PR53W Valve-Body Process Refractometers for ordinary and explosive areas

Vaisala Polaris™ PR53M and MEX PTFE-Body Process Refractometers for ordinary and explosive areas

Nesteiden pitoisuuksien mittaaminen

Vaisala tarjoaa laajan valikoiman räätälöityjä tuotteita eri alojen nestemittaustarpeisiin.

Lue lisää refraktometriteknologiasta ja sen käyttökohteista ja tutustu tuotemateriaalikirjastoomme.

Eikö sovellustasi ole luettelossa?

Tässä on listattu vain joitakin esimerkkejä refraktometrin käyttösovelluksista. Luvassa on satapäin lisää!

Sovellusasiantuntijamme auttavat sinua. Kerro lisätietoja täyttämällä lomake tai ota meihin yhteyttä.