Learn more about refractive index in solvent swap processes

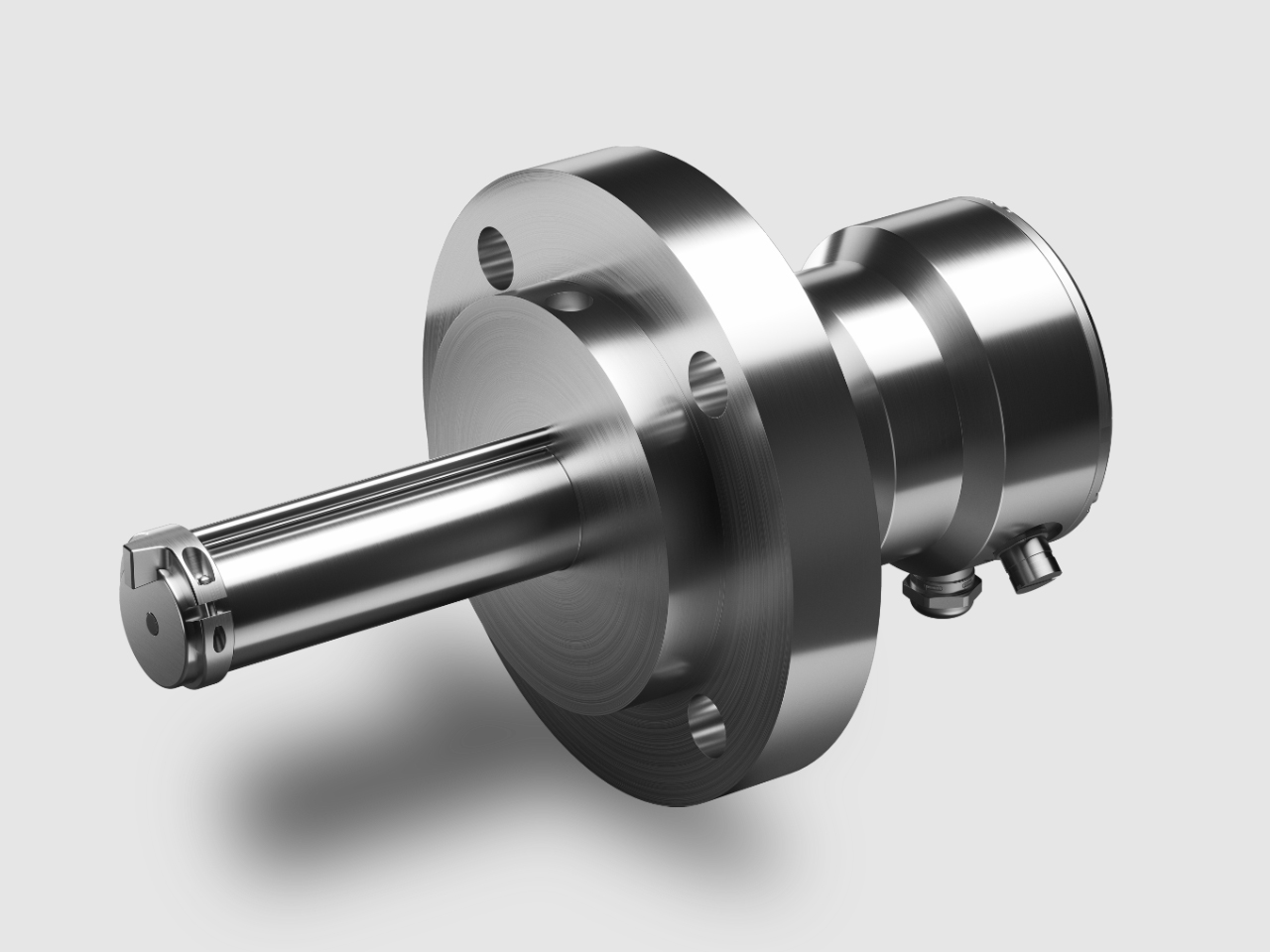

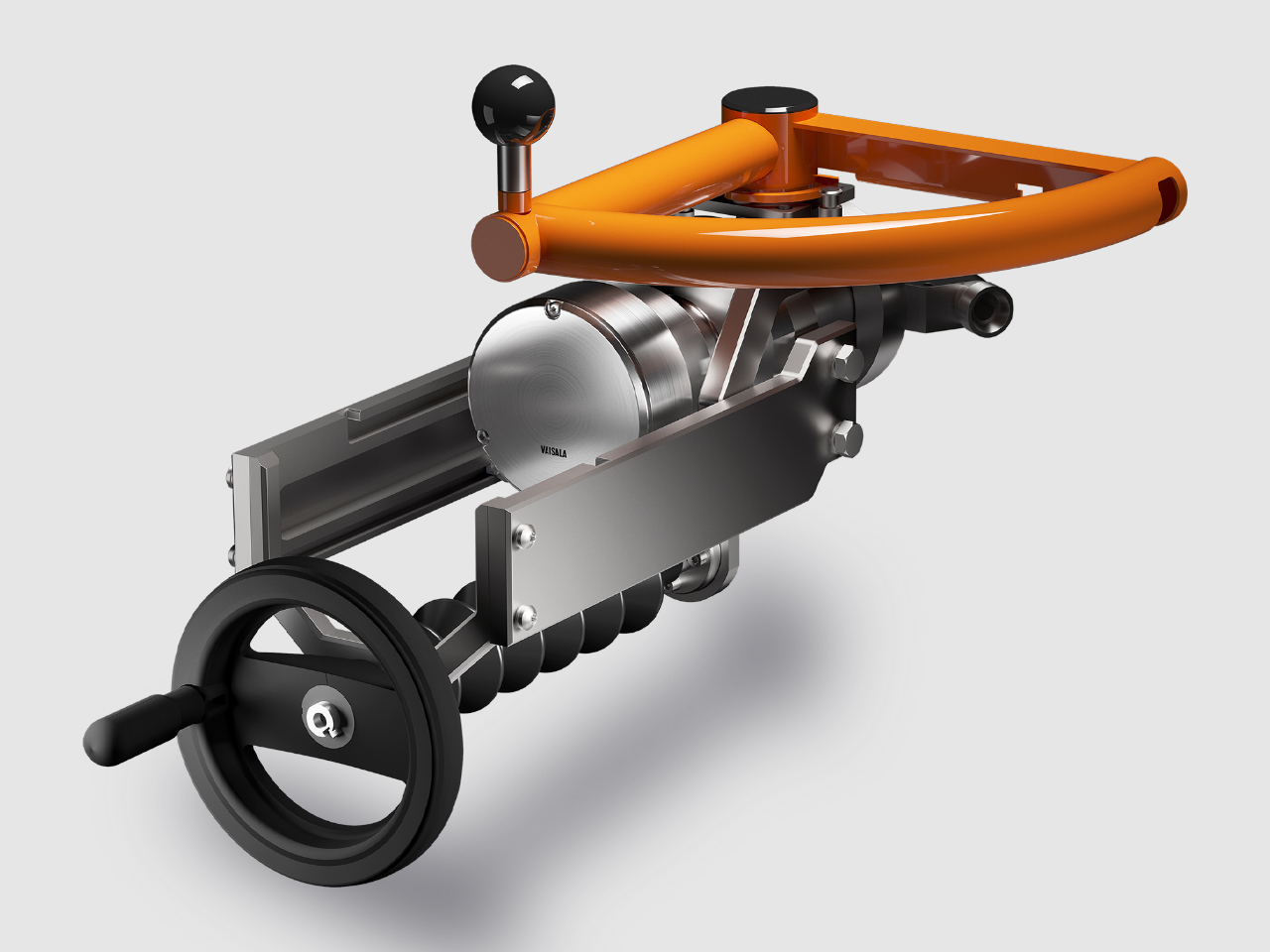

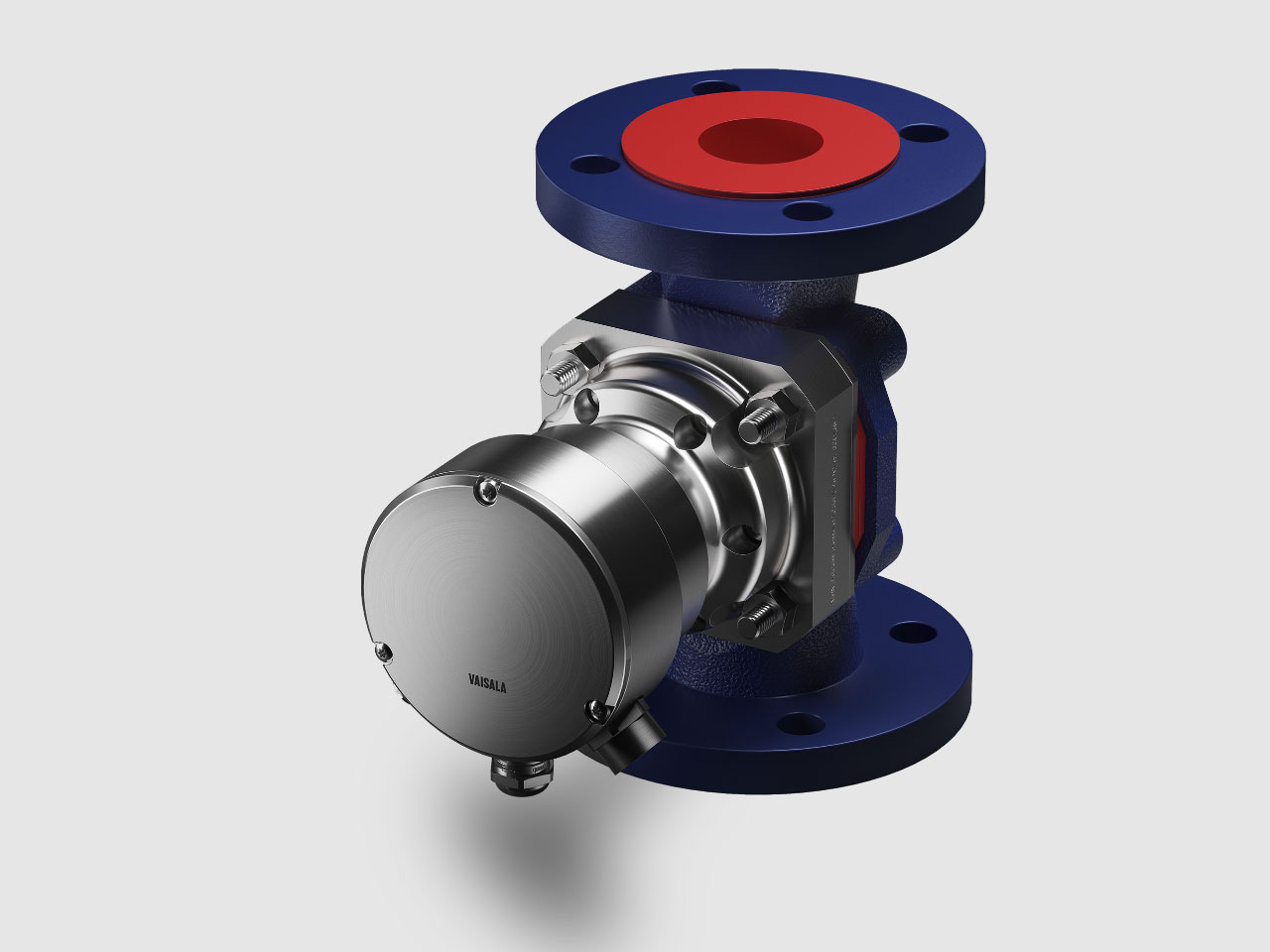

Download our application note on how to use refractive index measurements to optimize and troubleshoot solvent swap processes. The note gives an overview of refractive index technology and includes recommended installation points for best performance.