Monitoring organics in food and beverage side-streams or wastewater streams

Introduction

The Food, Beverage and Brewing industries use high quantities of water and generate high-organic strength wastewater. Organic pollutants are problematic to the environment as their decomposition process consumes the oxygen contained in the receiving water. The oxygen in the water can be consumed at a greater rate than it can be replenished, causing oxygen depletion and severe consequences to the stream ecology.

Organic pollutants from the food and beverage industry include oils and fats, alcohol, proteins and carbohydrates.

Wastewater generated from the production needs to be monitored to ensure compliance with environmental regulations. Major pollutants are often defined by Chemical Oxygen Demand (COD) or Total Organic Carbon (TOC). Organics monitoring helps food and beverage facilities to detect quickly and accurately the carbon content in their wastewater streams. Excess organics can incur fines and penalties. In severe cases the plant can even be closed.

Application

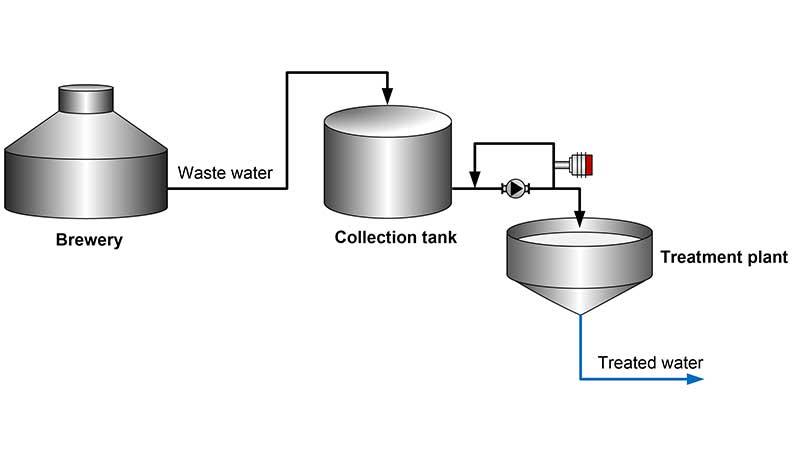

Food and beverage facilities, e.g. breweries, progressively try to minimize their environmental load by monitoring and treating their effluent before discharge. TOC and COD are the most common parameters used for water quality.

It is difficult to achieve an efficient operation of the wastewater plant because of the constant changes in the influent properties. To avoid these load shocks to the treatment plant, the effluents from the process are commonly stored in collection tanks.

At that point, the water is analyzed and treated according to its organic content. For example, water with a low COD content is sent to the treatment plant, while the water with a high COD is treated in a reactor first.

Traditional COD and TOC testing methods are off-line and time consuming, rendering them unsuitable for real-time control. While TOC can be measured on-line by conductivity and non-dispersive infrared (NDIR) based methods, these analyzers are expensive to maintain and calibrate, resulting in frequent breakdowns in their operation.

Food and beverage facilities require a reliable and inline measurement of organics content in the effluents. Real-time control and monitoring of the effluent provide the wastewater treatment plant with instant warning of exceptional loads and help to optimize its operation.

Typical end products

- alcohols

- proteins

- sugars

- fats

- beer

- other food and beverage products

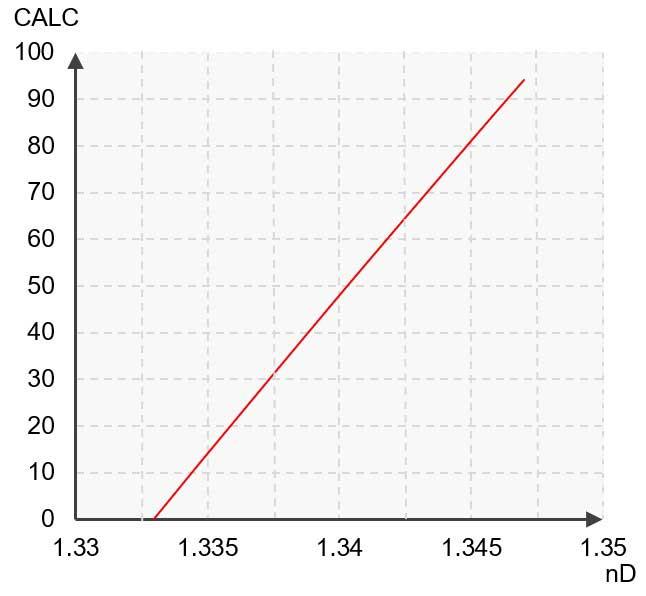

Chemical curve: R.I. per g/L COD at Ref. Temp. of 20˚C

Instrumentation and installation

Vaisala Polaris™ PR53 Process Refractometer provides reliable and continuous measurement to estimate the pollutant content in the water from the production facilities. The refractometer’s measurement is accurate and requires no recalibration.

The refractometer measures the refractive index of the effluents providing instant information on the amount of dissolved solids. The refractive index technique has proven to be a successful method for effluent monitoring as it has good correlation with COD and TOC values.

Typical measurement range is 0-10000 ppm (COD or TOC). The refractometer provides Ethernet and 4-20 mA output signals that can be connected to the process controller for real-time control. For instance, alarms can be set at 6500 ppm and the pump shutoff at 7500 ppm. The alarms are a reliable method for indicating a large amount of dissolved solids (high organics) to the treatment plant.

Similarly, the refractometer can be installed in the discharge lines within the production facilities. Water of suitable quality can be recycled to reduce costs and the demand of water supply. Moreover, the integration of continuous water quality monitoring in the production areas provides real-time alarm of product losses allowing quick corrective actions.

The refractometer is installed directly at the dispersing pipe’s outlet of the effluent sewer. The refractometer can read 0-1 % total dissolved solids that correlates with 0-10000 ppm TOC scale.

With the refractometer’s reliable and real-time measurement, the wastewater plant can adjust their operation for the incoming load, reduce the treatment cost, and increase their efficiency to meet the environmental regulations.

Vaisala Polaris process refractometers

The Vaisala Polaris PR53AC Sanitary Compact Process Refractometer (pictured) is for hygienic applications. Convenient installation directly to process lines with standard sanitary and Type N couplings, or with a sanitary flow cell. CIP and SIP cleaning.

The Polaris PR53GC Compact Process Refractometer is suitable for a wide range of industrial applications. Special alloy materials are available for demanding environments. Convenient installation with type L coupling. A selection of flow cells available.