Total Organic Carbon (TOC) monitoring and control in wastewater streams

Introduction

The sugar and sweetener plants are required to monitor and control the organic load in effluent streams. Excess organics, e.g. alcohols and sugars, in various wastewater streams can incur fines and penalties. In severe cases the plant can even be closed.

Before treatment and recycling, the quality of the water must be defined. Traditional methods are Total Organic Carbon (TOC) and Chemical Oxygen Demand (COD) tests.

Refractive index has proven to be a very successful measurement method for organics monitoring in these effluent streams, as the TOC level is typically high (up to 10000 PPM).

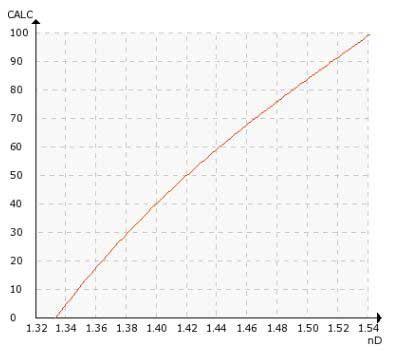

Chemical curve: R.I. per BRIX at Ref. Temp. of 20˚C

Application

In sugar and sweeteners processing plants, effluent streams containing sugar, or sweet water streams, are generated in different plant processes, such as ion exchange columns regeneration. The environmental load from the mills is reduced with water treatment and by recycling the used water whenever possible.

Wastewater treatment plants need to know the incoming TOC to keep the treatment process in proper operation and compliant. TOC monitoring is particularly important to warn the treatment plant about excess organic concentration.

TOC has traditionally been measured both on- and off-line. Conductivity and non-dispersive infrared (NDIR) are the two common detection methods used in on-line TOC analyzers. However, these analyzers are expensive to maintain and calibrate and are susceptible to frequent breakdowns in their operation.

Laboratory off-line sampling and testing is used to confirm the TOC analyzer readings. Although these tests are accurate, potential TOC load shocks may get missed if sampling and analysis are not performed often enough.

To control the effluent effectively and provide the wastewater treatment plant with warning of exceptional loads, the measuring instrument used must be reliable and in operation at all times.

Typical end products

- alcohols

- proteins

- sugars

- fats, etc.

in various effluent streams in the corn sweetener and beer brewing industries.

Instrumentation and installation

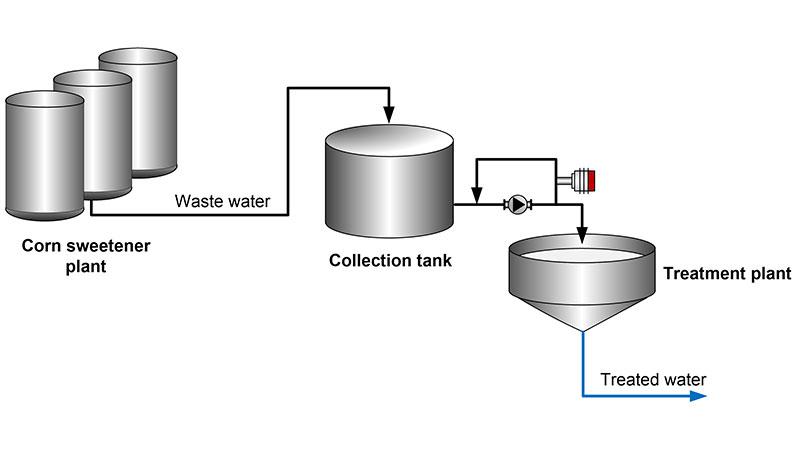

Vaisala Polaris™ PR53 Process Refractometer provides in-line and real-time indication of TOC content in wastewater by means of dissolved solids measurement. The refractometer is installed before the sewage proceeds to the treatment plant to inform the incoming TOC level and keep the treatment process in proper operation and compliance.

The process refractometer acts as a watchdog to provide reliable alarms for high-levels of incoming dissolved solids, which is an indication of high organics concentration. The refractometer’s output signal can be used to create alarm and control strategies to improve the operation of the wastewater plant. For instance, alarms can be set at 6500 PPM and the pump shut-off point at 7500 PPM.

The output signal from the refractometer can also be used to detect water of sufficient quality for re-use in the process. Recycling water will reduce the volume of waste and the environmental impact of the mill to a great extent.

The refractometer PR-53 provides in-line measurement of the effluent sewer at its dispersing outlet to the treatment plant. The refractometer can read 0-1 % total dissolved solids that correlate with 0-10000 ppm in TOC scale.

Vaisala Polaris Compact Process Refractometers

The Polaris PR53GC Compact Process Refractometer (pictured) is suitable for a wide range of industrial applications. Special alloy materials are available for demanding environments. Convenient installation with Type L coupling. A selection of flow cells available.

The Vaisala Polaris PR53AC Sanitary Compact Process Refractometer is for hygienic applications. Convenient installation directly to process lines with standard sanitary and Type N couplings, or with a sanitary flow cell. The product is also compatible with clean-in-place (CIP) and sanitation-in-place (SIP) systems.

User Interface

Vaisala Polaris process refractometers are compatible with the Indigo platform, offering plug-and-play connectivity, user-friendly interfaces and service and configuration tools. The Indigo520 transmitter adds a physical user interface, data logging, advanced diagnostics, automatic wash control, and access to measurement settings and parameters.

Measurement range

Refractive Index (nD) 1.3200 – 1.5300, corresponding to 0-100 Brix.