Hydrogen peroxide vapor probes and analog connectivity

View video in full screen mode.

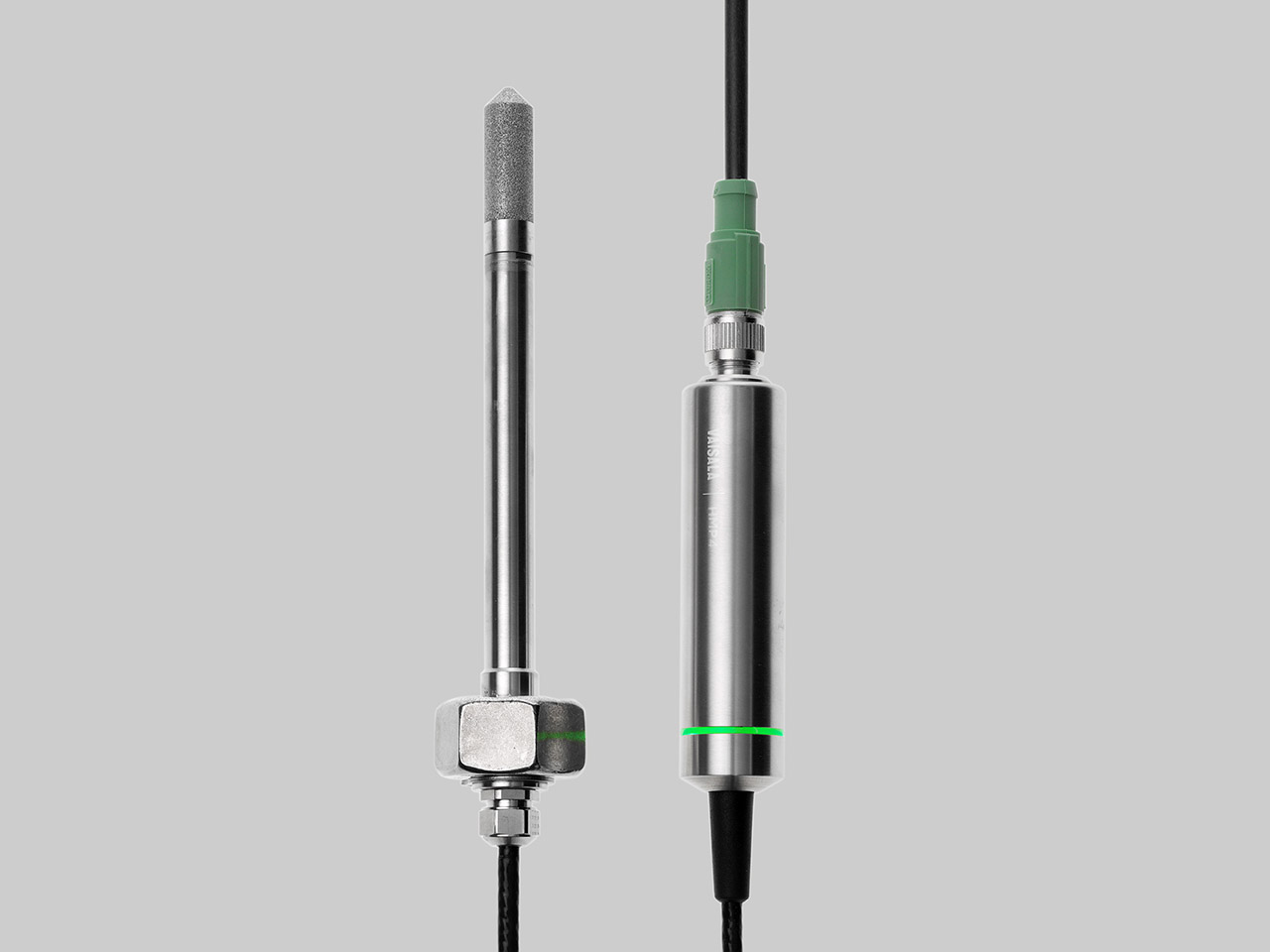

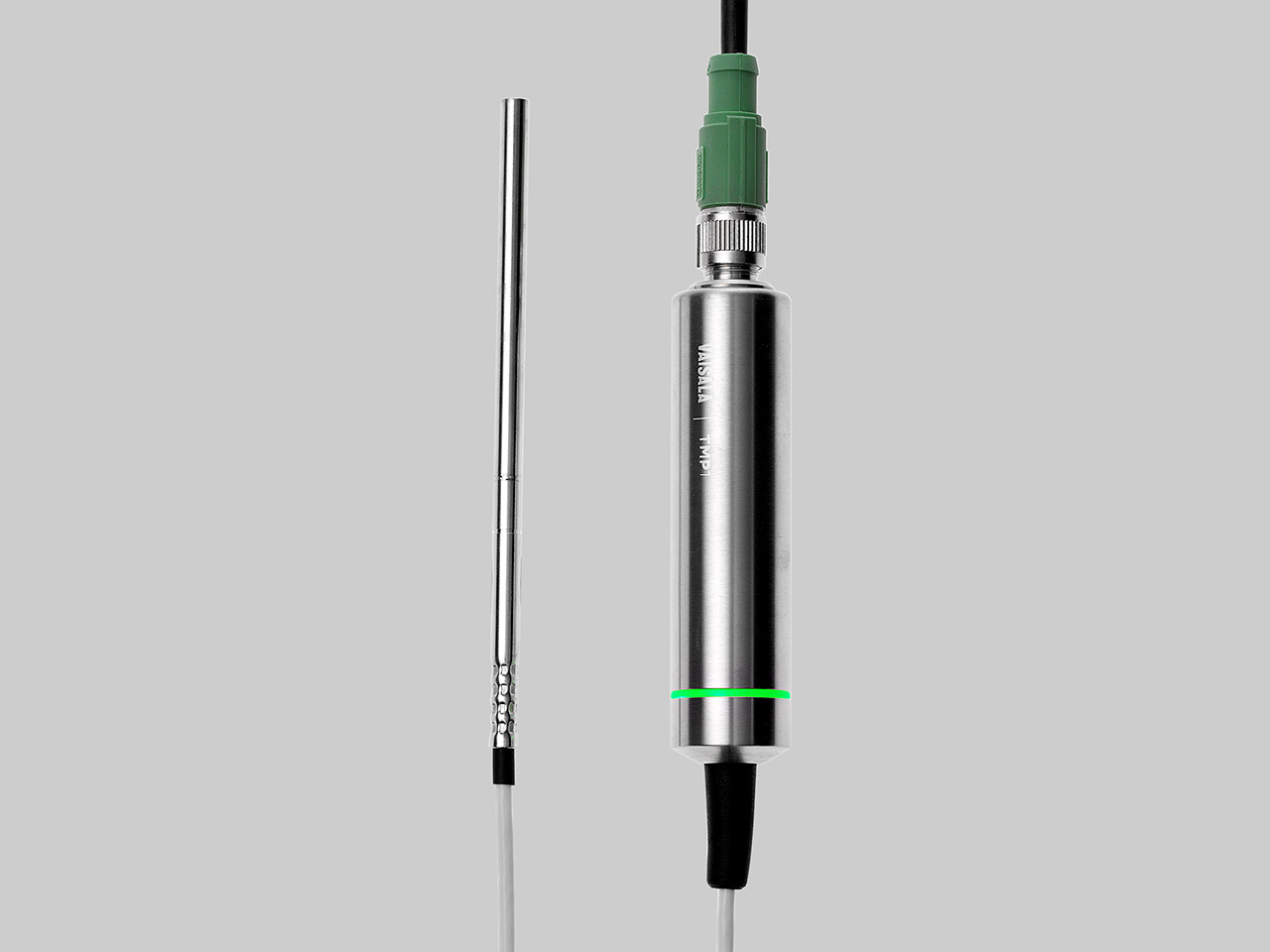

I have here an HPP270 probe for measuring vaporized hydrogen peroxide in bio-decontamination processes. It measures vH2O2 concentration and humidity as relative saturation. There are fundamentally two different ways to connect this probe to your control or data acquisition system. You can connect it as a standalone probe or use a Vaisala host device (Indigo transmitters), which provides additional features.

Learn more about Indigo transmitters in this blog: “Do I need an Indigo transmitter or just an Indigo probe?”

Please leave any questions you have in the fields below

Vaporized Hydrogen Peroxide, Humidity and Temperature Measurement HPP270 Series

The Vaisala PEROXCAP® Hydrogen Peroxide, Humidity, and Temperature Probe HPP270 series probes are designed for demanding hydrogen peroxide bio-decontamination.

Indigo200 Series Transmitters for Vaisala smart probes

Vaisala Indigo200 series transmitters are host devices for displaying measurement values from Vaisala's Smart Humidity, Temperature, Dew Point, Moisture in Oil, CO2 and H2O2 Probes.

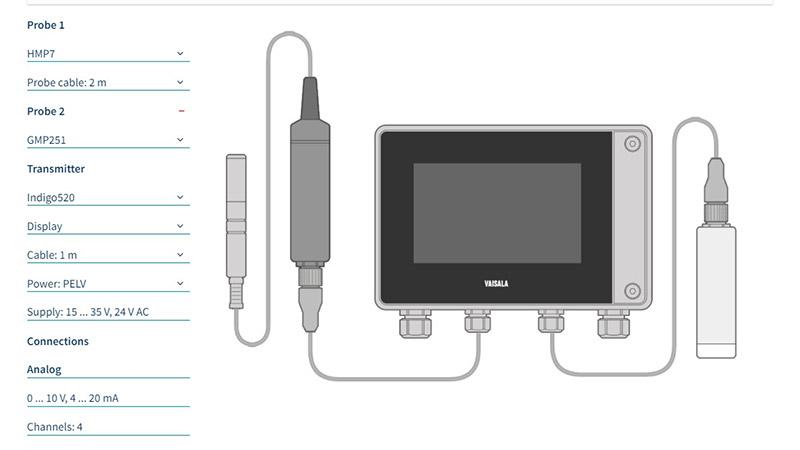

Indigo500 Series Transmitters

The Vaisala Indigo500 series transmitters are host devices for Vaisala Indigo-compatible, stand-alone smart probes. The Indigo500 series include multi-functional Indigo520 transmitter and Indigo510 transmitter with basic features.

Monitoring & controlling with smart vH2O2 sensor technology

Comment

Muhammad Saeed Gohar

Janice Bennett-Livingston

Thank you for your question!

I have passed your enquiry along to our sales team. A Vaisala representative will reach out to you by email.

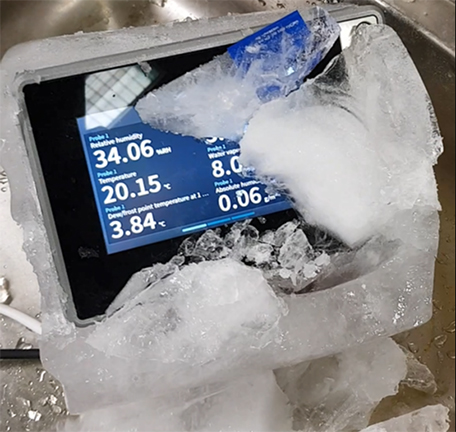

Even though the Indigo probes can be used as a standalone measuring instruments, using them together with an Indigo transmitter is highly recommended. For example, having a local display in the transmitter is useful, when something isn’t clear or there’s a problem, or when performing maintenance work in the field. Hidden costs may decrease considerably. For example, data from probes is shown on the transmitter display, allowing users to view what is going on.

Even though the Indigo probes can be used as a standalone measuring instruments, using them together with an Indigo transmitter is highly recommended. For example, having a local display in the transmitter is useful, when something isn’t clear or there’s a problem, or when performing maintenance work in the field. Hidden costs may decrease considerably. For example, data from probes is shown on the transmitter display, allowing users to view what is going on.