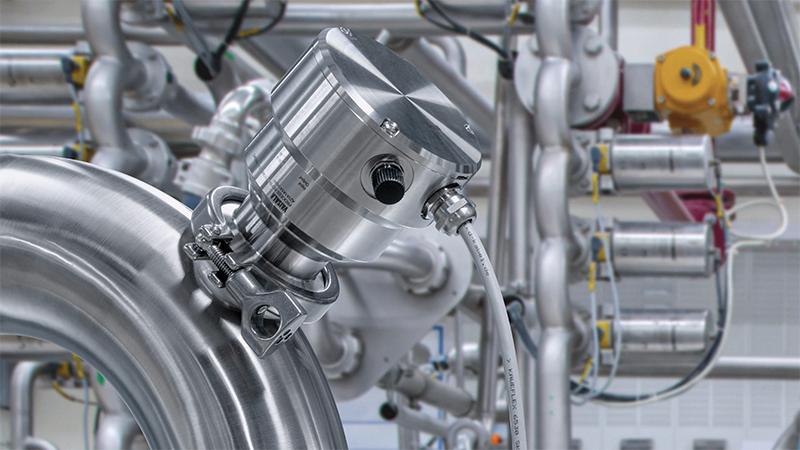

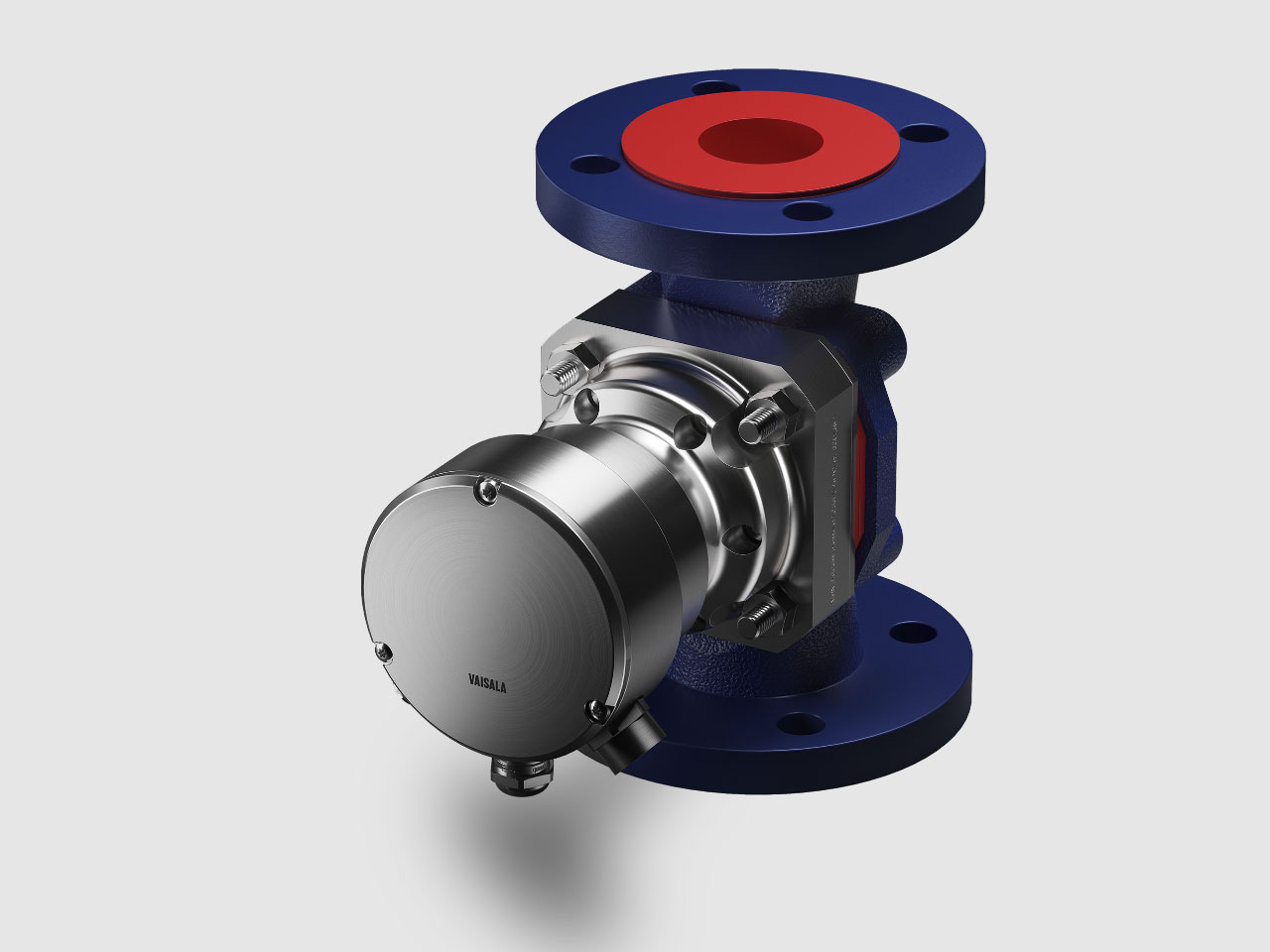

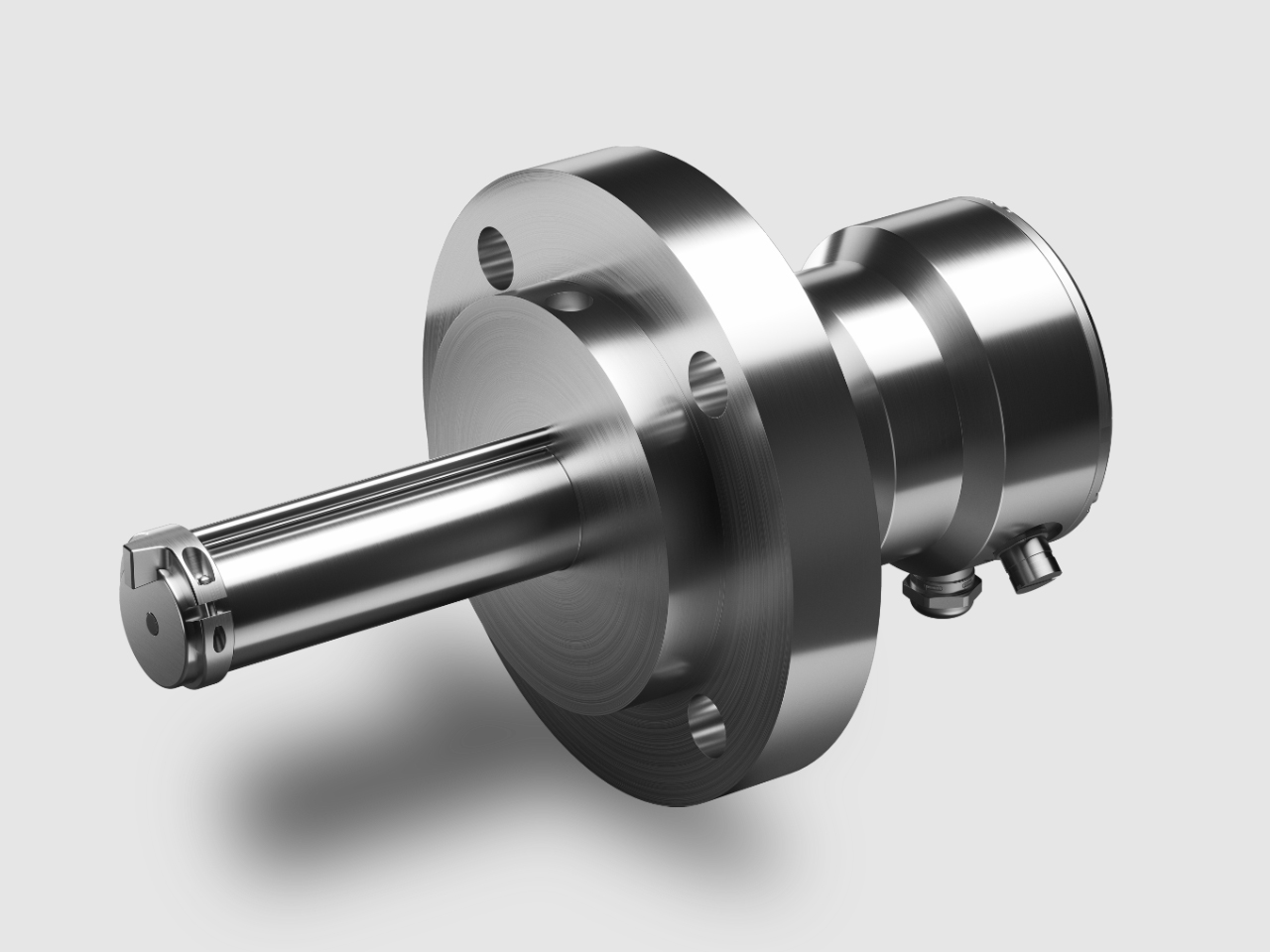

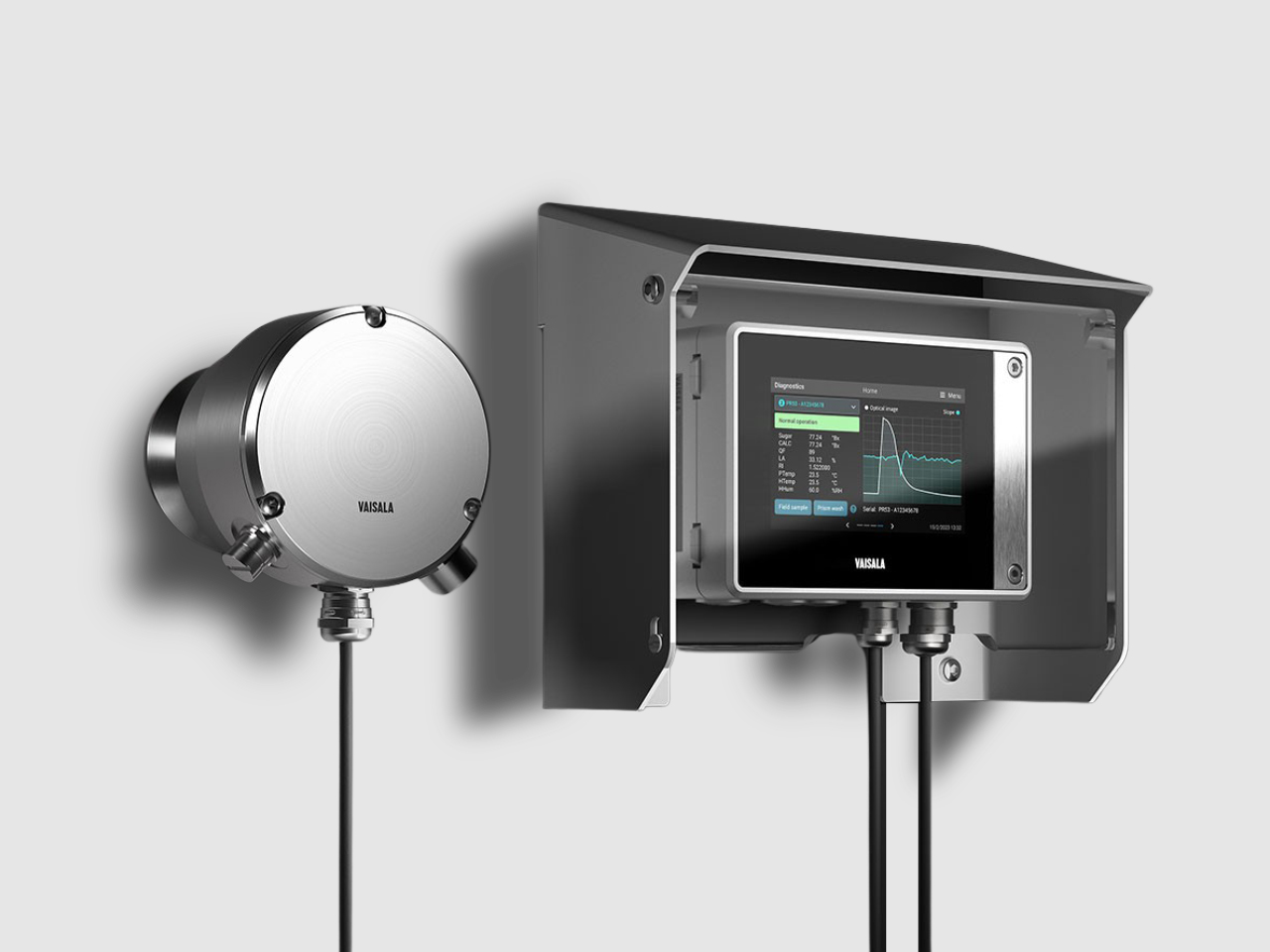

Mastering Sulfuric Acid Measurement: Successes in Oil & Gas Refinery Operations

In this webinar, Vaisala Industry Expert Kevin Green is joined by two experts from Elessent Clean Technologies . Together they discuss how sulfuric acid is used as a catalyst to facilitate the alkylation reaction.