Cold/Hot Spots: How Many Probes Are Really Needed for Stability Chamber Monitoring?

- Read more about Cold/Hot Spots: How Many Probes Are Really Needed for Stability Chamber Monitoring?

- 8 comments

We recently received a question about placing temperature and humidity probes for monitoring stability chambers, based on where the hot and cold spots are found.

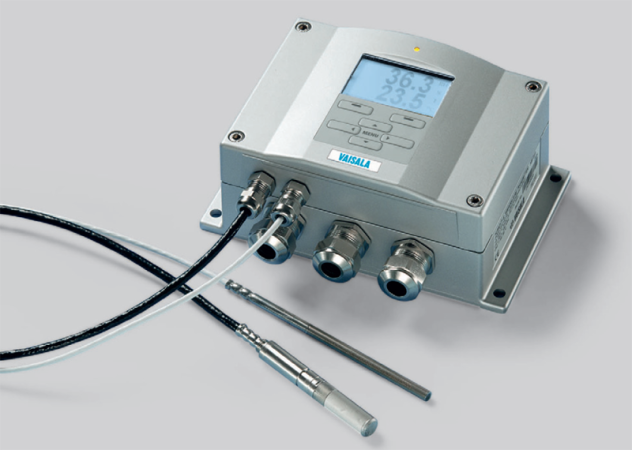

To learn more about our newest solution for environmental monitoring, our product manager's email below, or visit our viewLinc page.

Stability Chamber Monitoring Probes

Hi Paul,

I'm a Senior Validation Engineer at a global medical company specializing in eye care products. I learn a lot from Vaisala's webinars, so thank you!

I have a question about stability chambers…We have many stability chambers that have both temperature and RH specs, typically ±2° C and ±5%RH. We do empty-chamber mapping as part of OQ and full-load mapping as part of PQ. My question is this: If the highest temperature, highest RH, lowest temperature and lowest RH are in four different places, do we then need to monitor with four probes?

Then (even worse) what if some of these locations are different under full vs empty load? Do we then need even more probes for monitoring? If yes, we could conceivably end up with eight probes for monitoring. A couple of our chambers have only two monitoring probes in place, so our concern is that they don't account for the highest and lowest parameters. Any help you can provide is appreciated!

J

Paul answers:

Dear J,

I'm very pleased to hear you have found our webinars useful! We hope you make use of our archived webinars.

Your question is a common one. Unfortunately, the scenario you have described is not well addressed in guidance documents. My hope and expectation is that we will start to see more formal answers for this question.

Before I answer, I want to acknowledge that the ways we typically analyze our mapping data creates a monitoring perspective that I consider to be an artifact of mapping, and not necessarily representative of our goals in monitoring.

To ensure I'm not being vague… let me try to explain further. We analyze our mapping data as efficiently as possible, finding the maximum and minimum values during the mapping, and noting where they occurred. This focus on the maximum and minimum values comes with the unspoken understanding that every other measurement at every other location would therefore be between these two identified max/min values. Every measurement in the mapping is still important, as each one serves to demonstrate that our chamber has the ability to maintain the required uniformity. However, we focus on the maximum and the minimum, the legendary hot and cold spots, mainly as an artifact of our analysis.

The question that I want to ask is: Are the hot spot and the cold spots actually important? Or is our focus on them only the result of the way we analyze mapping data with statistics? Why is it that we are effectively ignoring the other 99.99% of the data that says the equipment is performing as expected?

Of the hot and cold spots are important, but that's only if they are out of specification, or close to the limits. But are they important when they are in spec? I simply think that our analysis technique makes us focus on them, giving them greater weight than they may deserve.

To further explore this idea, I searched through the available guidance. I found no guidance that stipulates anything like this: "After mapping, place a monitoring probe at the hot spot and another at the cold spot." What the majority of guidance says is something linguistically similar, but categorically different.

Guidance tends to say something more like this: "After mapping, place monitoring probes in a way that takes into account the results of your mapping, including any hot and cold spots."

The words used barely differ, but the difference is big.

Further, looking at 20 years of pharmaceutical experience, almost every controlled environment I have seen has the monitoring probe in a location that makes logistical sense – protected enough so the probe isn't damaged, and on a wall or column to ensure it can be mounted to prevent movement. In very few instances I have seen monitoring probes placed at the actual hot or cold spot, which is often within the storage area to be used. Placing a monitoring sensor in the working spaces causes some problems: the probe either gets damaged, moved, or hidden in product which dampens its ability to respond to changes in air temperature.

Most people compromise by choosing a sensible monitoring location on the wall of the chamber, but calculate offsets to virtually monitor the hot and cold spot. This sounds like a sound approach on the surface, but this approach presents challenges. You end up with the logistical nightmare of managing a multitude of specialized offset alarms, and the math to determine the measurement process uncertainty is beyond the training of most non-metrologists.

So, we have an interesting conundrum. Guidance appears to tell us the hot and cold spots are important. In practice, almost no one monitors their exact hot and cold spots. And those that attempt to do so run into serious logistical issues.

My approach has always tended to be pragmatic. Map the chamber. If it passes the mapping, (empty, loaded etc.) then it is validated. The chamber will continue to be validated so long as the set-point is maintained, so long as PMs are regularly performed, so long as annual calibrations are performed. Then I make sure the probe, usually a single probe (unless the space exceeds 20 cubic meters) is in a safe, sensible location, representative of product storage, out of direct airflow from the heating/cooling system, and where the impact of door openings can be sensed, but without causing nuisance alarms.

Because the chamber is validated, I can rely on my monitoring sensor to tell me when something is catastrophically wrong – door left open, compressor failed, power lost, etc. Because I validated the chamber I am not worried that one part of it will be out-of-spec by 0.5C for 15 minutes. If my chamber barely passed validation and I am so worried that it will not maintain temperature uniformity that I feel the need to monitor the hot/cold spots with multiple probes, then I probably need a new chamber.

Because the chamber is validated, I can rely on my monitoring sensor to tell me when something is catastrophically wrong – door left open, compressor failed, power lost, etc. Because I validated the chamber I am not worried that one part of it will be out-of-spec by 0.5C for 15 minutes. If my chamber barely passed validation and I am so worried that it will not maintain temperature uniformity that I feel the need to monitor the hot/cold spots with multiple probes, then I probably need a new chamber.

In some sense, a multitude of monitoring probes starts to look like trying to test quality into the product, which is known to be an inefficient way to ensure quality. The more practical approach is to design a process that inherently ensures quality. In this case, it might simply be tighter limits during validation, or purchasing a higher performance chamber that can maintain a tighter temperature and %RH uniformity. If you need a multitude of probes, it might be a sign that you need to improve the quality inherent in your process.

If your product is particularly expensive, or it is particularly sensitive to small temperature changes, that shifts the risk equation and you might consider an additional probe, or monitoring product temperature instead of air temperature, as a way to gain additional confidence in your environment. But for a "normal" product, especially a product in final packaging, more than one probe may be unnecessary.

Thank you again for asking; your question is both timely and relevant because the need for adequate mapping and monitoring has increased due to the expansion Good Distribution Practices.

Sr. Regulatory Compliance Expert / Validation Program Manager

Paul Daniel

Comment

Paul Daniel

You are asking a question that does not have a clear answer from the available guidance and regulations. The best you can do is make a choice that is logical, and document that rationale.

The identification of hot spots and colds spots is a by-product of our statistical analysis of mapping data. If we simply figure the overall max and the overall min, and verify it is within our acceptance criteria or specification, we have just found the simplest path of data analysis. And along the way, we identified the hot and cold spots. But does this really mean that the hot spots and cold spots are important? Or are they just a by-product of how we analyze the data?

Personally, I think hot/cold spots do not matter if the overall max and min are within specification. In this case we have just proven by qualification study that the particular chamber can operate as intended - end of story. I think monitoring probes are there to detect catastrophes and disasters, things like doors left open, failed compressors, power outages, etc. If not what are they there for? To tell us what is going on with the product? Impossible. There is no way one or two probes can accurately predict what is going on inside the dynamic environment of a chamber, so we can't rely on them for data about what the product has experienced. we only know that there has been a problem. I think this position is supported by actual industry practice, where there is historically only one probe in small chambers, and that probe is almost always located in the same place (side wall, same side as the door handle, middle height, about 20 to 30 cm from the front)

I just said "I think..." a lot. Does it matter what I think? Does it matter when some guidance says to pick a monitoring location based on (not "at") the location of the not and cold spots? Does it matter when a guidance says to actually place a probe at the hot spot and one at the cold spot? This you will have to decide for yourself. Just because something is in a guidance doesn't mean it is the best idea for your situation.

This is what we know:

*We should definitely re-qualify and re-map periodically based on risk.

*We will determine hot and cold spots (as an analysis by-product) each time we do this.

*We may see hot and cold spot locations changing from year to year. (If all measurements are otherwise in spec, I don't see why it matters.)

If you think it matters, you may need to explain it. But if it is in spec, I would simply explain use the spec as the acceptable limit of variation and say "It doesn't matter".

*If you base your SOP for monitoring probe location on the hot spot or cold spot location, then you may have created a problem for yourself. This seems like a good reason to change that policy.

Another pathway in this is to talk to the chamber manufacturer. These guys are required by law in some countries to map their units extensively, with the expectation that all units of the same model number will behave the same. And it is in their best interests to map as a good mapping tells them the best place to put their control probes and monitoring probes. They will likely share their data with you privately to help you answer this question.

I hope this helps!

Bhavna Aggarwal

Paul Daniel

Technically, the answer is “Yes”. But it takes more work than just adding a “no loading zone” sign. And it may create more problems than it solves.

First, doing this will absolutely get the attention of an auditor. So, you want to make sure you do it right. Don’t rely on a sign, because people don’t pay attention to signs. You need to put a physical cage in place that prevents people from using the space, but is of a design that will not block airflow.

But how big do you make this cage? Since you only have one location that was out of spec, you really don’t know how big the “no loading zone” should be. The only safe way to define this space it to extend it all the way to the sensors that were within specification. This will take up about a third of the available space in your chamber, if you mapped with 9 sensors. If you want the “no loading zone" cage to be smaller, you will need to do some additional mapping to prove the remaining available storage space is viable and is in specification.

This spot that is out of specification could be a sign that the unit needs repair or is too old. It may be a better pathway to do some maintenance on the chamber and tuning of the control system, and try to improve the performance of the chamber. You might even want to consider replacing the unit if you can’t improve the performance, especially if it is a critical piece of equipment, such as a stability chamber.

I would even support placing sensors in a temperature buffering material before I would support taking a section of it out of service as a “no loading zone”. This can be a workable solution if your have known product volumes stored in the chamber, such that you can simulate smaller volumes with a buffered sensor. While I would rather not attract the attention of an auditor, I would rather defend a temperature buffering approach, than try and explain my rationale for the borders of a “no loading zone”.

In summary, yes you can mark an area as “do not use” or “no loading zone”, but you must be able to force people not to use it (e.g. by using a cage, not just a sign), and you will have to justify the boundaries of your cage with some additional mapping. While it may solve your mapping problem, it brings bigger problems because of the loss of storage area, the increased mapping effort, and the increased audit attention.

I hope this helps!

Hemant Kumar G

I Have a doubt that how many probes should be used for a walk in chamber of volume 19280 litres?

Paula Daniel

Thanks for the question.

Your chamber has a volume of 19.28 cubic meters. Thankfully, this falls just under 20 cubic meters. This means you can use the guidelines presented in the ISPE’s Good Practice Guides on Cold Chain Management, and Controlled Temperature Chambers Mapping and Monitoring. In these guidance documents, they recommend starting with 15 sensors. One in each corner (8 probes), one in the geometric center (1 probe), and one in the center of each plane or side of the chamber (6 more probes). In addition to these 15 probes, you would want to add a few extra at points of interest, such as the controller probe, display probe, or monitoring probe.

As an alternative, you could follow the guidance of the WHO. They will tell you to put a stack of three (low, middle, and high) in each corner (12 probes to start), and then a distribution of additional sensors in high-risk areas – by the door, near the output of the HVAC system, on other shelves within the space. This will end up being close to 20 probes.

So, either by following the methodologies of either the ISPE or the WHO, you will need between 15 and 20 sensors to properly map a room or chamber of just under 20 cubic meters of volume.

Please be sure to document your probe locations and your rationale for your choices.

Best Regards,

Paul Daniel

Sr. GxP Regulatory Expert

renuka

I Have a doubt that how many probes should be used for a walk in stability chamber of volume 3000 litres? and how can we identify the hot spot and cold spot?

Paul Daniel

Best Regards,

Paul Daniel

i do read your blog for many queries that arise during work course.

they are very helpful. Thank you! :-)

i have a question...during area or controlled chamber tempertaure mapping studies.

is it a right practice to determine hot and cold zones during requalification (every year) temperature mapping for placing a continous monitoring probe?

what if these hot/cold spots change every year?

if the chamber already has more than one monitoring inbuilt sensor installed inside...periodic requalification is required?!