Evaporation process optimization

Evaporation is a core unit operation used in many industries to concentrate liquids by removing water or other solvents through heating. It’s widely applied in chemical production, food and beverage processing, sugar and pulp industry, pharmaceuticals, and wastewater treatment – but it is also one of the most energy-intensive unit operations.

Integrating Vaisala Polaris™ inline process refractometers into your evaporation process delivers operational advantages and cost savings through improved energy efficiency, consistent product quality, and process stability.

Challenges

High energy consumption

Evaporation is one of the most energy-intensive unit operations in industry, and inefficient concentration control leads to unnecessary steam consumption and higher operating costs

Risk of fouling, crystallization, or off-spec products

Even small concentration deviations can cause scaling, crystallization, or off-spec products, resulting in costly downtime and reduced production.

Fluctuating feed concentrations and process instability

Inconsistent feed composition and flow rates make stable evaporation difficult to maintain.

Need for reliable measurements in demanding conditions

Processes must meet strict food safety or chemical durability requirements, often under harsh temperature and cleaning cycles.

Vaisala Solution: Vaisala Polaris™ process refractometers

Vaisala Polaris™ process refractometers provide continuous, real-time in-line concentration measurement (Brix, dry solids, or TDS). Installed directly in evaporator inlets, outlets, or intermediate stages, they deliver accurate readings unaffected by bubbles, crystals, or undissolved solids. With options for sanitary, chemical, and heavy-duty environments, they fit a wide range of applications — from food, beverage, sugar, and dairy to chemicals and wastewater.

Liquid concentration measurement with refractive index

Vaisala offers a wide range of products tailored to the liquid measuring needs of different industries.

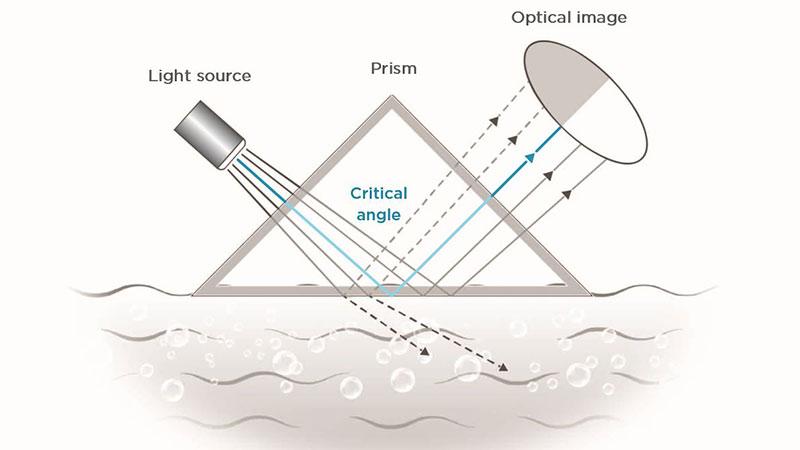

The refractometer operates on the principle of critical angle measurement. Inside the refractometer, there is a light source, a prism, and an image detector.

Learn more about the refractometer technology and its applications, and explore the library of product-related assets.

Benefits

Consistent product quality

Maintain exact concentration targets to ensure downstream processes run smoothly and final products meet specifications.

Lower energy use

Optimize steam and feed flow for efficient, sustainable operations that reduce operating costs.

Maximized yield

Safely push evaporators closer to their capacity limits without risking fouling, product loss, or downtime.

Process reliability

Real-time, accurate data enables automatic control and stable operation even with fluctuating feed conditions.

Applications

Vaisala refractometers support evaporation control in:

Food & Beverage

Juices & coffee and tea processing

Fruit & Vegetable processing

Food Ingredients, Additives and Flavors

Dairy Products

Sugar & Sweeteners

Pulp & Paper

Kraft (Sulfate) Pulp Process

- Black liquor evaporation (Kraft (Sulfate) Pulp: Evaporation)

Chemical & Biochemical Manufacturing

Common chemicals

Fibers & Plastics

Biochemicals

Environmental & Wastewater Treatment

Industrial Wastewater

Vaisala Polaris

With real-time concentration control, evaporation processes become more predictable, efficient, and profitable.