Wastewater and effluent monitoring

Wastewater treatment is essential in the food & beverage, sugar, chemical, and pulp & paper industries to protect the environment, meet regulatory requirements, and maintain efficient manufacturing. Side-streams and effluents from production processes must be carefully monitored to ensure compliance and avoid costly penalties or environmental harm.

Reliable monitoring also helps optimize treatment processes and reduce operational costs.

The Vaisala Polaris™ inline process refractometer enables continuous, real-time monitoring of dissolved solids in wastewater streams by measuring the refractive index of effluents. This immediate insight allows industries to detect elevated levels of dissolved contaminants as soon as they occur, supporting early intervention and prevention of process upsets or abnormal contaminant levels. With instant data, operators can take immediate action—such as diverting or treating waste before it reaches municipal systems - helping ensure compliance with environmental regulations and discharge permits. Installed directly in pipelines, it delivers real-time data enabling rapid response to changing contaminant levels.

Challenges

Wastewater treatment processes face multiple challenges that affect compliance, operating costs, and long-term sustainability.

Permit compliance risks

Insufficient monitoring can cause effluent to exceed discharge limits, leading to fines or surcharges.

Hidden losses and unstable flows

Undetected product leaks and fluctuating streams drive up costs, waste, and energy use

Manual sampling delays

Intermittent or delayed lab results mean problems are often discovered too late for proactive intervention

Maintenance and downtime

Inadequate monitoring can lead to equipment fouling, higher sludge volumes, and unpredictable operations

Vaisala Solution: Vaisala Polaris™ process refractometers

Vaisala Polaris™ process refractometers deliver continuous, real-time inline measurement of dissolved solids in wastewater streams. Installed directly in process lines, they provide reliable data unaffected by bubbles and suspended solids. Proven in demanding food, beverage, and industrial wastewater environments, refractometer’s reliable and real-time measurement allows wastewater plants to adjust their operation for the incoming load, reduce treatment costs, and increase their efficiency.

Liquid concentration measurement

Vaisala offers a wide range of products tailored to the liquid measuring needs of different industries.

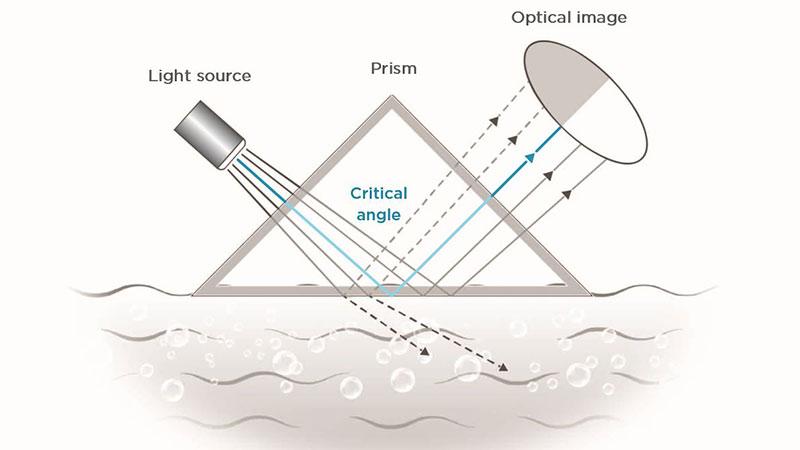

The refractometer operates on the principle of critical angle measurement. Inside the refractometer, there is a light source, a prism, and an image detector.

Discover more about the refractometer technology and its applications, and visit the library of product-related assets.

Benefits

With Vaisala’s real-time measurement, operators gain multiple benefits that improve efficiency, reliability, and compliance.

Ensure compliance

Keep effluent quality within permit limits and avoid penalties

Cut operating costs

Reduce chemical dosing, aeration time, and overall energy consumption

Improve process stability

Optimize treatment despite fluctuating organic loads and inflows

Support sustainability

Minimize sludge, waste, and environmental footprint

Trusted reliability

Robust design ensures long-term, low-maintenance operation

Applications

Vaisala refractometers support wastewater monitoring in:

Sugars and Sweeteners

Side-stream treatments

Food and beverage

Side-streams and wastewater treatment

Effluent and water treatment

General industrial applications

Oil refining & Petrochemicals

Effluents treatment

Vaisala Polaris

With real-time monitoring, wastewater treatment becomes more predictable, compliant, and cost-effective.

Resources

More about Evaporation process optimization

Learn how inline concentration measurement enhances efficiency in upstream evaporation processes across industries such as food & beverage, pulp & paper, and chemical manufacturing.