How real-time compressed air dew point monitoring improves quality, efficiency, and reliability for Walki

For Finnish material conversion specialist Walki Oy Valkeakoski (Walki), compressed air is the lifeblood of their production processes. A continuous monitoring system based on Vaisala’s world-leading humidity measurement transmitters – and delivered by integrator SmartAir and Energy Oy (SmartAir) – is helping Walki to improve quality, efficiency, and reliability.

Walki produces consumer and industrial packaging materials as well as engineered materials for the construction industry. The company is part of Japan-based Oji Holdings, one of the world’s largest paper and packaging producers. Its plant in Valkeakoski, southern Finland, is one of 16 operated by the company.

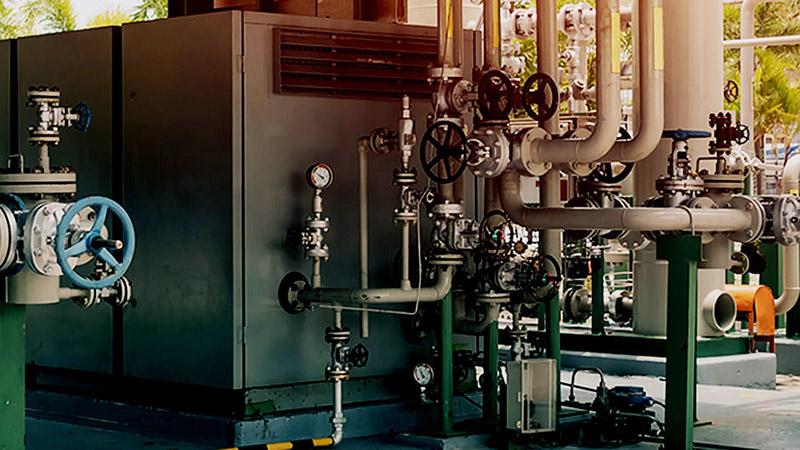

Walki production facilities in Valkeakoski. Image credit: Walki.

Compressed air plays a critical role in virtually every part of the plant’s five production lines and the compressed air used must always be of the highest quality. Walki's production requires consistently dry and clean compressed air, so moisture control is essential for quality and equipment durability.

Lack of situational awareness with spot checking

Previously, Walki had been relying on spot checking using the Vaisala Indigo80 handheld indicator to check values at different points in the compressed air production and distribution system. These checks were performed by experts from SmartAir, a leading Finnish provider of modern, ecological, and energy-efficient compressed-air engineering.

“Although spot checking with the Indigo80 was giving staff at Walki reliable dew point measurements, the data only provided a snapshot of the situation at that moment in time. Without continuous monitoring, there was a lack of situational awareness – with no way to track the dew point in real time, analyze data for trends, or respond quickly to potential problems,” says Sami Uusi-Erkkilä, CEO of SmartAir.

Another challenge was the significant variation in dew point values seen at different measurement points. Some of these variations could be attributed to environmental conditions, which add an extra layer of complexity. Part of the compressed air network piping runs outside the plant, meaning temperature fluctuations can affect dew point readings, especially during cold winter periods.

From periodic spot checking to real-time continuous monitoring

To address these challenges, Walki turned to SmartAir to design and implement a continuous monitoring system – PVS SmartAir – for the compressed air network at Valkeakoski. The system is based on Vaisala’s DMT143 miniature dew point transmitter, which is designed specifically for use in compressed air dryers and other similar applications.

“The DMT143 has a wide measurement range and is an extremely robust product with a long calibration interval,” says Juhani Lehto, Product Manager at Vaisala. “Most importantly for Walki’s application, it has an extremely fast response time, which is critical in continuous monitoring systems. It can also recover quickly from condensing conditions because of the built-in probe warming functionality.”

The PVS SmartAir continuous monitoring system measures dew point at two different places in the compressed air network using DMT143 transmitters:

- Immediately after the adsorption dryer in the plant’s compressor station

- At the end point of the compressed air network after the production lines

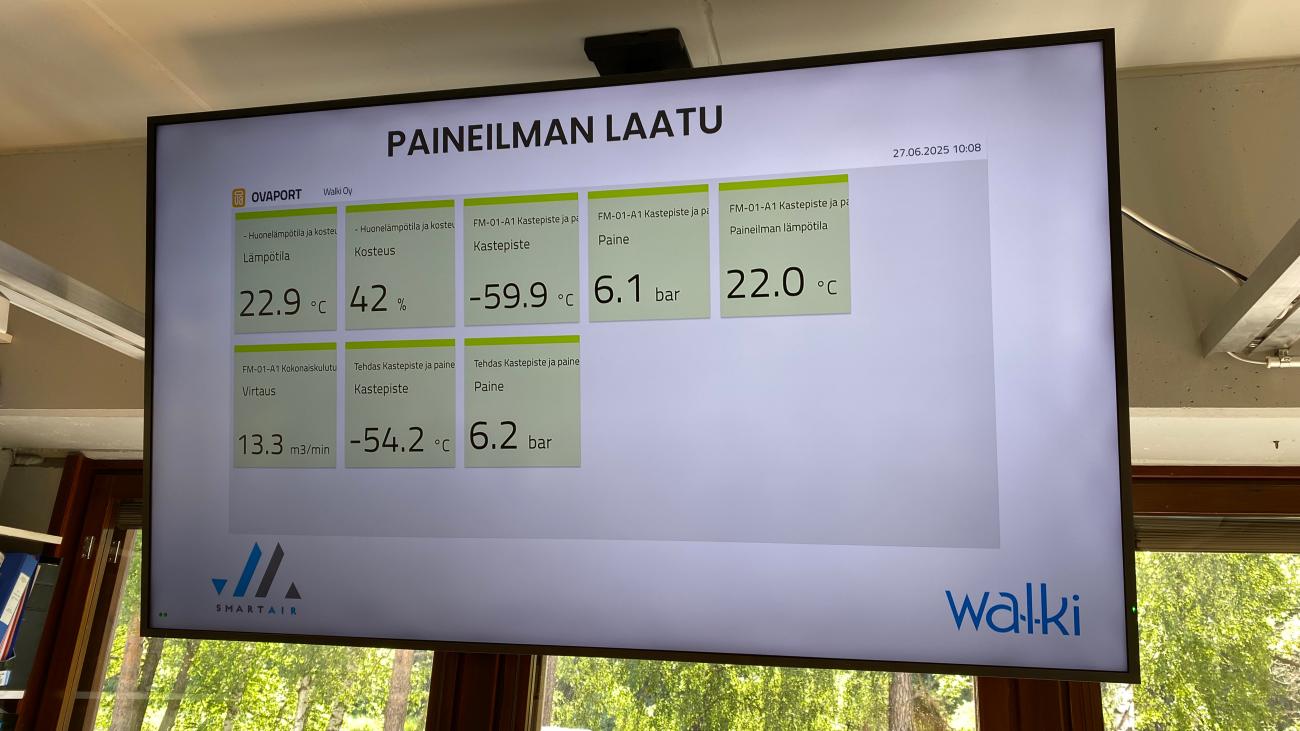

The system also measures compressed air pressure, flow rate, volume, temperature, and the ambient temperature, with all the measurement data is integrated into one interface. Measurement values are shown on a display in the maintenance office and are color coded to make it easy to spot anomalies. Green indicates that the values are within set limits, while red indicates a potential problem.

“This real-time data gives staff at Walki far better situational awareness and means they can act immediately should an alarm be triggered,” Uusi-Erkkilä says. “They can also access all measurement data remotely via a mobile app or browser-based application, which is particularly helpful in a plant that operates 24/7.”

The system can also provide reassurance that everything is working as it should, even if there are minor temporary variations in dew point measurement data. As an example, SmartAir was able to show that small, regular spikes in the values could be attributed to switching from one desiccant tower to the other in the compressor station.

Fast response to problem situations

The continuous monitoring system has proved its worth to Walki on several occasions, notably during a dryer malfunction in the summer of 2024. The malfunction caused a rise in moisture levels, and readings from the DMT143 transmitters provided an accurate picture of the situation.

The system triggered an automatic alarm when the dew point in the compressed air network reached -25°C. The displays in the control room gave a visual indication of the problem, and key personnel were automatically alerted by email. The ability to react rapidly to the problem allowed Walki to prevent the issue from negatively impacting their production processes.

Monitoring the quality of compressed air at Walki in Valkeakoski. Image credit: Sami Uusi-Erkkilä.

Reliable data protects production quality and efficiency

Walki has been very satisfied with the positive impact that the PVS SmartAir system investment has had on their daily operations and long-term performance.

They benefit from:

- Less uncertainty and faster decision-making with access to reliable dew point data around the clock.

- Improved production consistency and quality with fewer shutdowns, more reliable equipment performance and better product quality.

- Better maintenance execution and investment planning with accurate long-term data that is easy to share among relevant personnel.

- Potential cost savings through optimized dryer operations.

A constantly evolving system

The PVS SmartAir system provides a solid platform to expand continuous monitoring across the plant. Compressor room temperature monitoring has been included alongside dew point monitoring, and even more measurement points will be included in the future.

The system provides Walki with a real-time picture of both compressed air consumption and quality. Plant operators can now see how much compressed air energy each machine line consumes and can optimize processes to reduce compressed air consumption. For example, the company has been able to reduce compressed air consumption of various blowing operations on the production lines by throttling the blowing flow or by adding a logic-controlled valve.

“Real-time monitoring through the PVS SmartAir system provides us with critical and timely information about potential deviations,” says Mikko Nurminen, Plant Service Manager at Walki. “With this information, we can take preventive action and avoid production downtime caused by interruptions in the supply of compressed air.”

In future, the system will be enhanced with the addition of particle measurement. This will allow Walki to verify the quality of the compressed air according to the ISO 8573 international standard, which specifies purity classes of compressed air with respect to particles, water, and oil.

Main image from left: Mikko Nurminen and Petri Parikka. Photo by: Sami Uusi-Erkkilä, SmartAir.