Semiconductor manufacturing

Top-notch silicon chips are made using sophisticated machines, processes, and knowledge. And behind successful processes are high-performing monitoring and measurement instrumentation.

Each silicon chip deserves to work as intended, and when created, using just the right amount of material, energy, and other resources.

Guarantee success with quality measurements

From wet to dry and back

From semiconductor wafer manufacturing, and microelectronics fabrication to packaging semiconductors, equip your critical processing steps with trusted and reliable measurements for stable quality, high yield, predictability, and cost-efficiency.

Our offering covers instruments measuring humidity, dew point, temperature, pressure, and wet chemistries’ concentrations. Each product produces precise data on the manufacturing environment, and provides superior accuracy, long-term stability, and rapid response time for process optimization, increased yield, safety and best-performing chips.

For these reasons, Vaisala is the preferred measurement partner for semiconductor manufacturers and MEMS foundries, semiconductor equipment manufacturers and OEMs, fab operators, and material suppliers.

From the front-end to back-end and all the way to the customer, we've got you.

Technology comparison

Review how Vaisala's dew point probe compares to CRDS' (Cavity Ring-Down Spectrometer)

and Chilled mirror transmitters in the most demanding operating environments, such as

rechargeable battery and semiconductor manufacturing.

| Vaisala’s dew point probe | CRDS | Chilled mirror transmitter | |

| Td measurement range* | -80 °C…+20 °C | -100 °C…-50 °C | -70 °C…+20 °C |

| In-situ measurement | Yes | No, requires sampling and a large pressure difference | No, requires sampling |

| Td accuracy in laboratory conditions* | +/-2 °C | +/-0.2 °C | +/-0.2 °C |

| Pressure range* | 1…50 bar | 1…5 bar | ~ 1 bar only |

| Dependency of atmospheric conditions | Not dependent | Dependent. Stable atmospheric conditions required. Sampling might generate errors in non-laboratory environment. | Dependent. Minimum dew point will raise if the ambient temperature increases. Sampling might generate errors in non-laboratory environment. |

| Response time* | Minutes | Tens of minutes | Hours |

| Sensitivity | High | Low (cannot detect quick changes, averaging measurement) | Low (cannot detect quick changes, averaging measurement) |

| Size | Small and light. Fits easily to multiple locations | Mid size, about 10 kg | From big and heavy to mid size |

| Operator to provide regular service | Not required | Not required | Required |

| Components requiring service | Not required | Not required, if in clean environment | Required (e.g., Peltier) |

| Local calibration/ support available | Yes | Unlikely | Unlikely |

| Dependency of background gases | Minor | Potentially strong | Potentially crucial |

* Typical values in battery and semiconductor manufacturing

WHY VAISALA

Designed for semiconductor manufacturing

Vaisala's comprehensive offering with just the right parameters provides stable measurements in semiconductor manufacturing.

Measurement accuracy designed in the product

Select products surrounded by an ecosystem of support, with optimized cost of ownership and with minimum lifecycle costs.

Avoid risks - select reliable products from wet to dry

Vaisala's products cover the whole measurement range, and everything you need from wet to dry, including products for specific applications.

Tailored products - Engineer-to-Order

Did you know that our products can be customized for a specific application or installation position?

Nothing gives us more joy than to solve difficult measurement problems, together with you. Contact us! We are here to help.

We walk the walk

Vaisala produces sensor chips for Vaisala products, and for R&D use in our own in-house cleanroom. We know what it takes to produce world-class quality.

In addition, Vaisala is committed to supporting our products throughout their entire lifecycle, and our expert services and support are located near you, wherever you are.

Semiconductor manufacturing applications

Environmental measurements in cleanroom, HVAC

Humidity control through air conditioning system, HVAC

Humidity levels can also impact the semiconductor manufacturing process. Excessive humidity can lead to condensation on sensitive equipment, potentially causing defects in the semiconductor devices. Precision air conditioning systems help to control humidity levels and act as a preventative tool.

Efficient room-wide monitoring for maximum process efficiency

By placing the probes strategically and at adequate intervals, the dry room or cleanroom can be monitored efficiently, ensuring comprehensive control of your entire room, whatever the size.

The DMP1 is optimal for maintaining process reliability and correct dryness levels in battery and semiconductor manufacturing with Indigo300.

Wafer cleaning with the help of durable products

Wafer cleaning is a critical process in semiconductor manufacturing for removing contaminants, particles, and residues from the surface of silicon wafers. This process ensures the reliability and functionality of integrated circuits (ICs) and other semiconductor devices.

Extra durability

Cleaning agents can include acids, various solvents, and water, and these residues might be present, thus requiring extra durability from measurement probes.

Vaisala offers corrosive resistant probes also without metal wetted parts, specially tailored for the wafer cleaning process, tolerating both high humidity and harsh chemicals.

It is important to ensure chip dryness after cleaning to prevent contamination and particle adhesion.

Temperature control for zero variations in the wafer patterns

Quality measurement probes in steppers offer stable temperature measurements and safeguard wafers from having variations in dimensions of the patterns induced by temperature fluctuations. Wrong dimensions on wafer patterns adversely affect the overall quality and performance of the semiconductor devices.

Humidity control for optics stability

The wafer stepper relies on precise optics to project and transfer patterns onto the wafer. Any variations in temperature or other environmental conditions can affect the stability and accuracy of these optics.

Barometric pressure control for accurate lithography, and process stability

Measuring barometric pressure is a must for optical precision and accuracy of the lithography process as barometric pressure directly influences the refractive index of air, which in turn affects the optics of the wafer stepper and the wavelength of lithography light.

Focus and depth control

Prevent defocused images by measuring and controlling barometric pressure with fast and accurate measurement instruments.

Wafer stepper in photolithography

Wafer stepper in photolithography is another critical processing step in the production of integrated circuits (ICs) and other semiconductor devices. In this step, a light pattern is projected onto a silicon wafer coated with photosensitive material (photoresist), thereby etching the desired pattern onto the wafer. As a result, some photolithography areas may have humidity tolerances as tight as ±1%.

Maintain chip prober machine ice-free with humidity control

The wafer probing machines identify defective wafers by testing chips. Tests are performed in cold temperatures, up to -40 Celsius ( -40 Fahrenheit) to ensure the chip works in extreme temperatures, for example, if later intended to be used in a vehicle.

The test environment must be kept dry, with the dew point temperature under -40 so that there is no ice deposition on the chip, which would later, when transferred to room temperature, turn to water and collect impurities on the chip.

Vaisala offers accurate dew point probes for the chip prober machines.

Keep ultra-pure gases ultra-pure

Protect expensive process gases from being contaminated by humidity. Gas quality significantly affects chip quality, as even trace impurities can lead to defects or failures. Moisture can react with certain materials or introduce defects during processes like oxidation.

A rapidly reacting probe will detect any moisture quickly and alert when reaching the set limit.

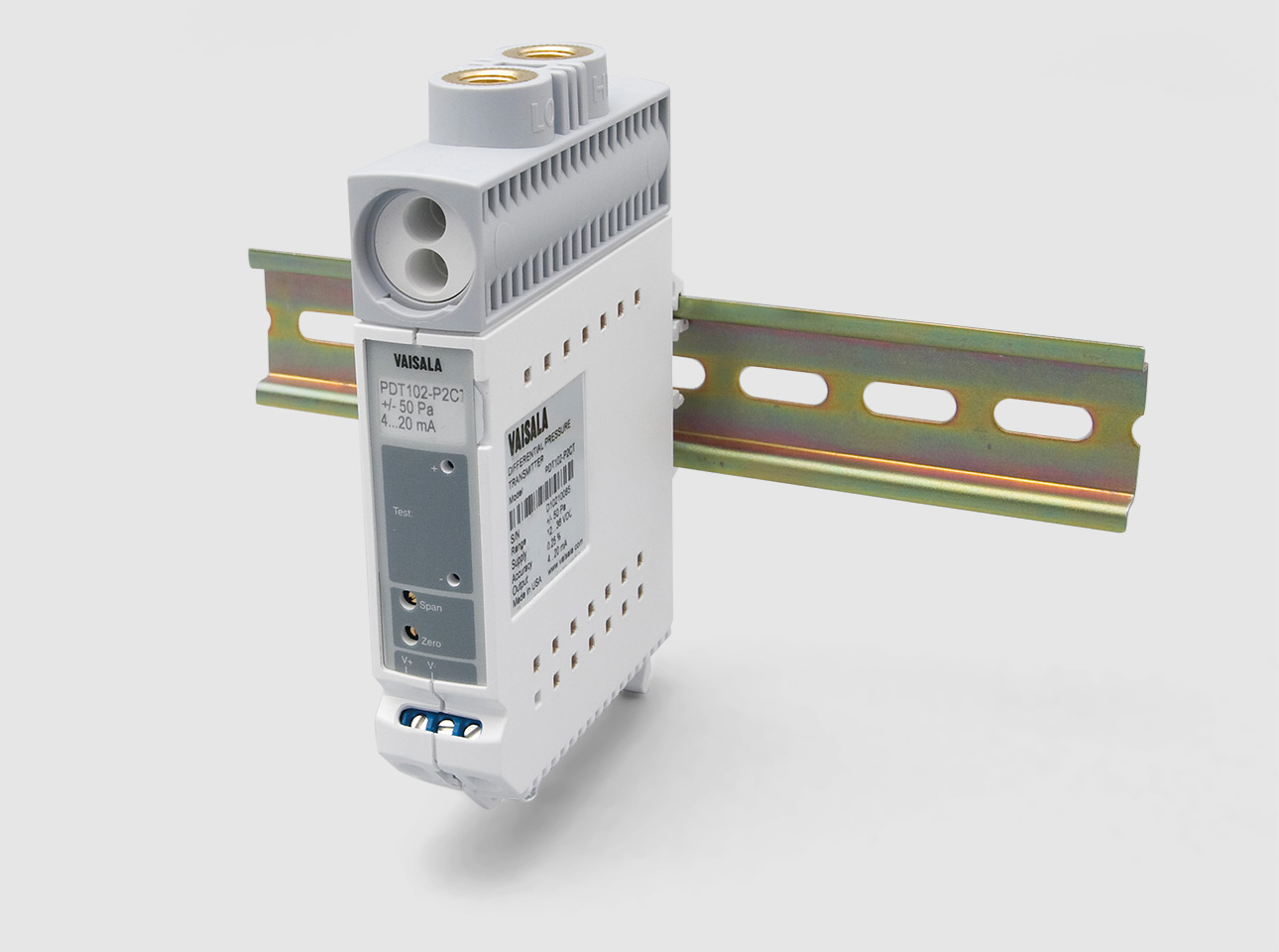

Secure differential pressure in a cleanroom

Easily keep the cleanroom differential pressure at ISO 14644 standards with our sensitive probes. With Vaisala's modular Indigo system, you can connect your differential pressure and humidity measurement probes to the same Indigo transmitter.

Get to know our differential pressure probes PDT101 and PDT102.

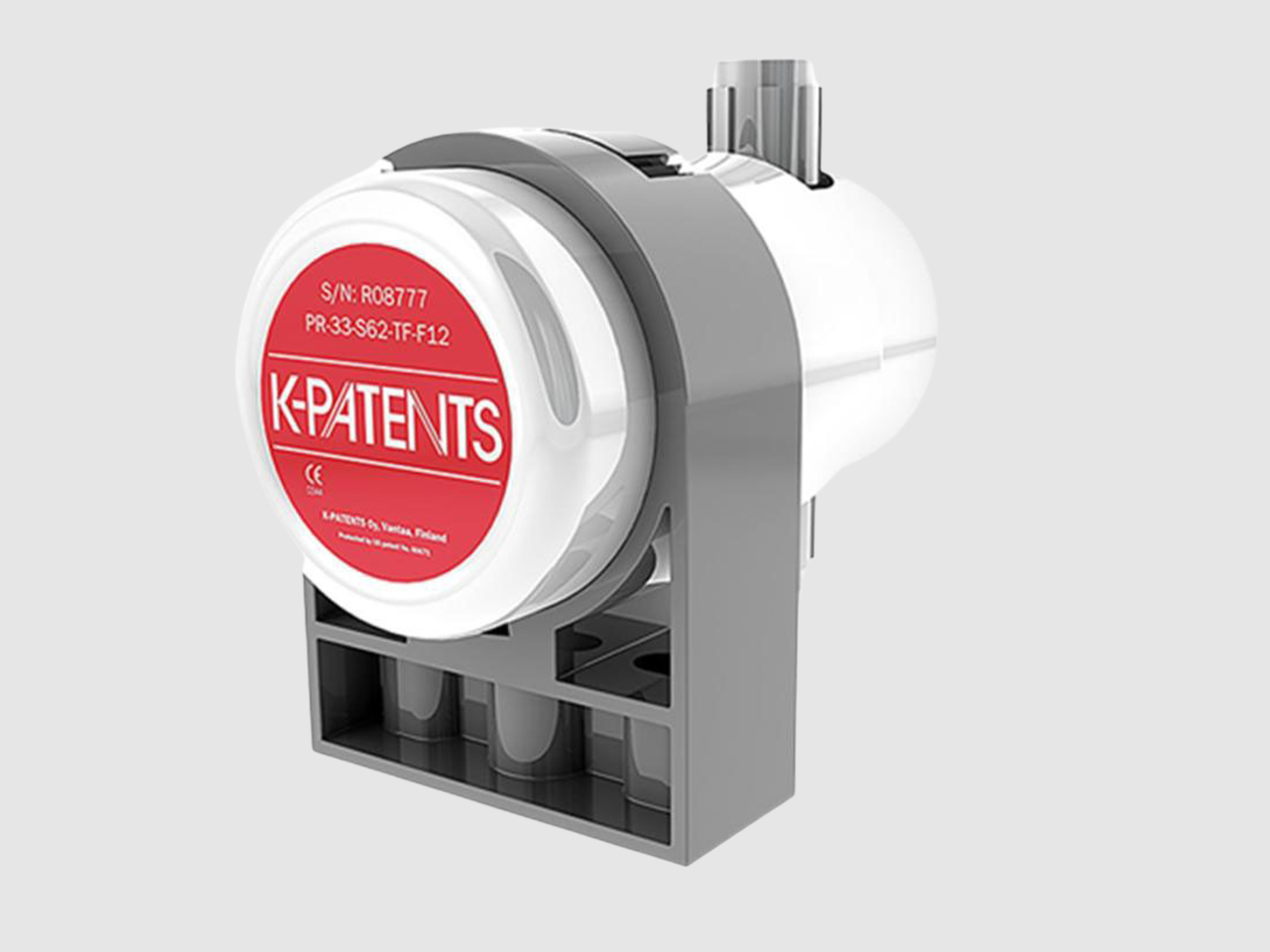

Optimize and measure wet chemistries' concentration in real-time

Semiconductor wafer plants consume tons of chemicals throughout the fab process. Ensure reliability of each chemical and avoid deviations from specification that can result in expensive equipment contamination and wafer scrap.

Expert content and customer cases

Dew point measurements best practices in semiconductor dry gases and wafer testing

Semiconductor ultra-pure gas can get contaminated down the line, and even trace moisture can ruin a chip. Learn how to keep your ultra-pure gases truly dry in this 30-minute, free webinar.

Why humidity measurements matter in semiconductor manufacturing

In semiconductor manufacturing nothing matters more than accuracy. One of the most critical parameters to measure is humidity, as maintaining exactly the right moisture levels is crucial for optimal equipment performance and end-product quality.

Semiconductor cleanroom best practices for humidity measurements

Semiconductor manufacturing is a delicate process, with many potential error sources. One is humidity. Excessive humidity can cause issues like condensation, whereas too dry conditions favors static charge build-up, potentially leading to damaging electrostatic discharges.

In this 30-minute webinar, our expert Juhani Lehto will cover extremes in humidity measurements in the semiconductor cleanroom, and shares measurement instrument installation best practices.

Semiconductor manufacturing related products

Dew Point Probe DMP1

Dew Point Transmitter DMT152

Dew Point and Temperature Probe DMP7

Indigo80 handheld measurement device

Indigo300 transmitter

Indigo500 Series Transmitters

Dew Point and Temperature Probe DMP8

Miniature Dew Point Transmitters DMT143 & DMT143L (Long)

Humidity and Temperature Probe HMP110

Differential Pressure Transmitter PDT102

Vaisala K-PATENTS® Semicon Refractometer PR-33-S

Try our dew point instrument finder

Contáctenos

¿Está interesado en recibir más información sobre una aplicación o producto específico? Envíenos un mensaje y nos comunicaremos con usted.