Prism wash systems and refractometers in chemical applications

In this blog, Kevin Green of Vaisala and Dave Lobach of Rocky Mountain Instrumentation answer several questions received during their webinar “Unlocking Efficiency: Refractive Index Insights for Chemical Industry Concentration Applications”. If you haven’t yet seen it, you are free to watch the recording.

Question: Do refractometers need a prism wash system?

Answer: A common question that arises in various challenging chemical applications is the necessity of prism wash systems. These systems are often required when there is a buildup or deposits in the piping or vessels that necessitate regular maintenance. Identifying the need for a prism wash system is crucial for maintaining the efficiency and longevity of the equipment. Determining the need for a refractometer prism wash system in chemical applications involves assessing whether there is a buildup or deposits.

When deciding to replace pH or conductivity measurements with refractive index, the need for a prism wash system can often be discerned from the process conditions and the maintenance requirements of the existing probes.

For more information, we have a blog on this topic: "How refractometer prism washing in challenging applications can create a competitive advantage".

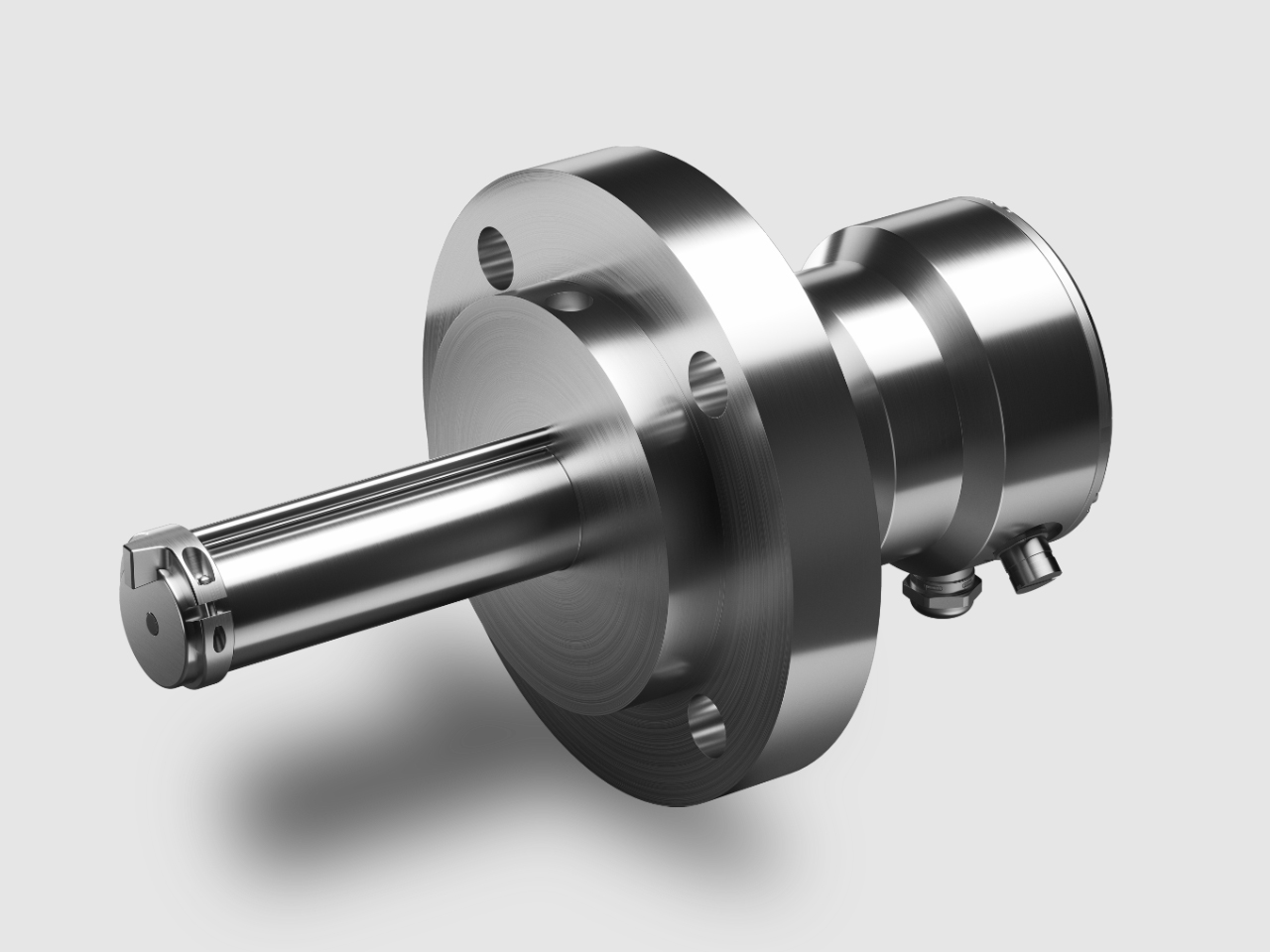

Question: Does the critical angle change with concentration or is it determined by prism?

Answer: The critical angle will vary depending on the concentration of the solution. Additionally, the number of facets and the angles at which the facets are cut in the prism determine the refractive index range. This relationship is essential for accurate measurements and optimal performance of refractometers. Learn more about the mechanical specifications of the prism in this data sheet.

Question: How many refractometers can be connected to an Indigo transmitter?

Answer: When it comes to integrating refractive index (RI) sensors with transmitters, two Vaisala Polaris sensors can be connected to a single Vaisala Indigo520 transmitter. Each Indigo unit has Modbus TCP/IP digital communication or four analog outputs that can be utilized for both RI and temperature measurements. This flexibility allows for comprehensive monitoring and control within various industrial processes.

Question: Can we monitor the amount of undissolved solids by monitoring the dark side of the reflection? (I.E., the number of spots or brightness)

Answer: While refractometers measure the total dissolved solids concentration, undissolved solids are typically measured with a density instrument. This measurement can then be used to determine the amount of insoluble product present in the process.

Question: Can refractive index measurement be used in Hydrocarbon and mineral powder slurry mixture?

Answer: Refractometry is a valuable tool in analyzing hydrocarbon and mineral powder slurry mixtures. It can assess the viscosity of hydrocarbons while ignoring the solids in the process. By providing detailed information about the chemical slurry mixture, refractometers can offer precise and reliable measurements, which are essential for optimizing production and ensuring quality control.

We have a related application note: "Natural gas liquids NGL: Liquid hydrocarbons identification"

Learn more about liquid concentration measurement for process control and optimization in chemical applications.

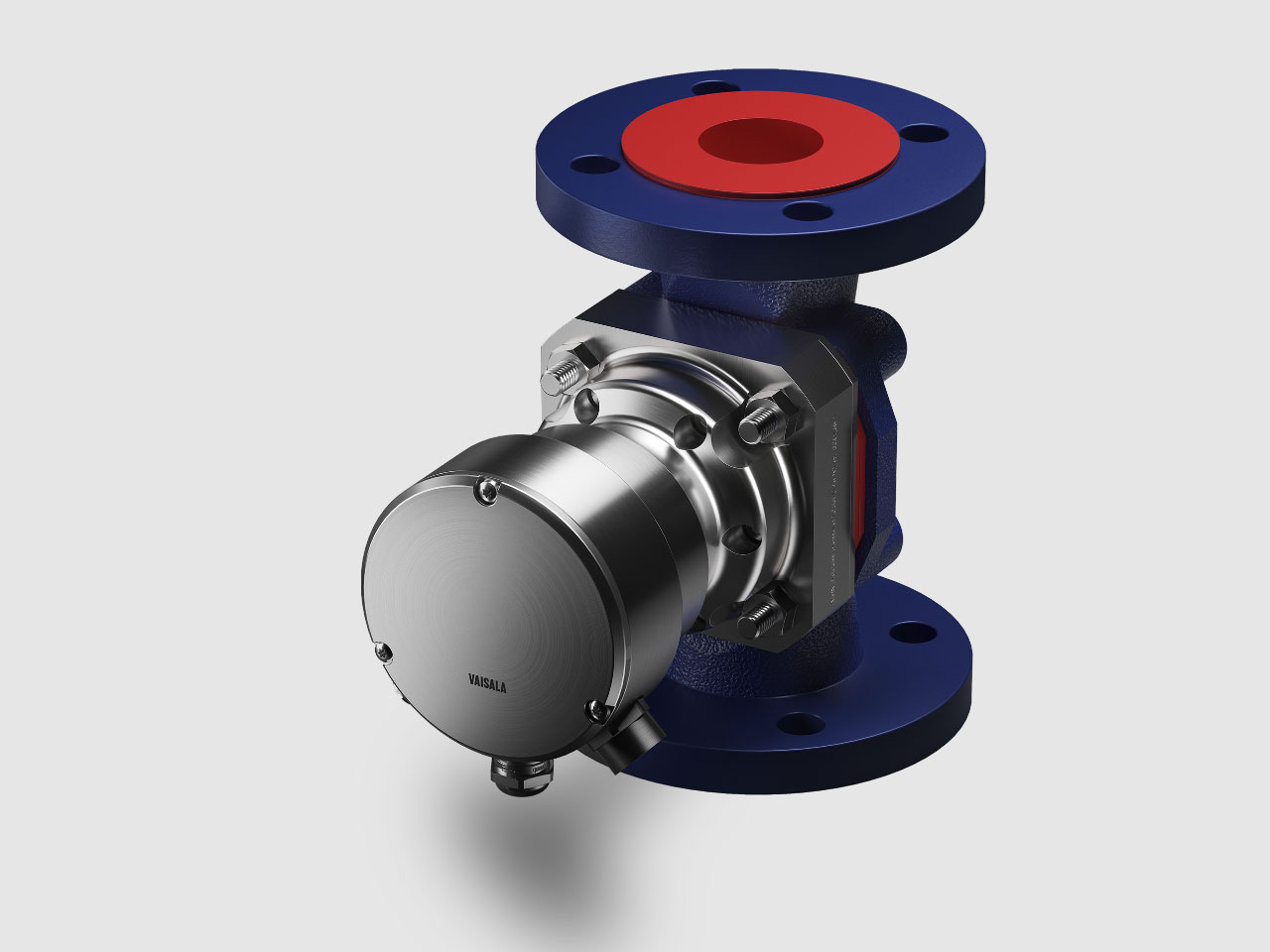

Vaisala Polaris™ PR53GC and GCEX Compact Process Refractometers for ordinary and explosive areas

Measure concentrations of acids, alkaline solutions, alcohols, hydrocarbons, solvents and various other solutions directly in pipeline, in production transport and quality control in chemical and other industries

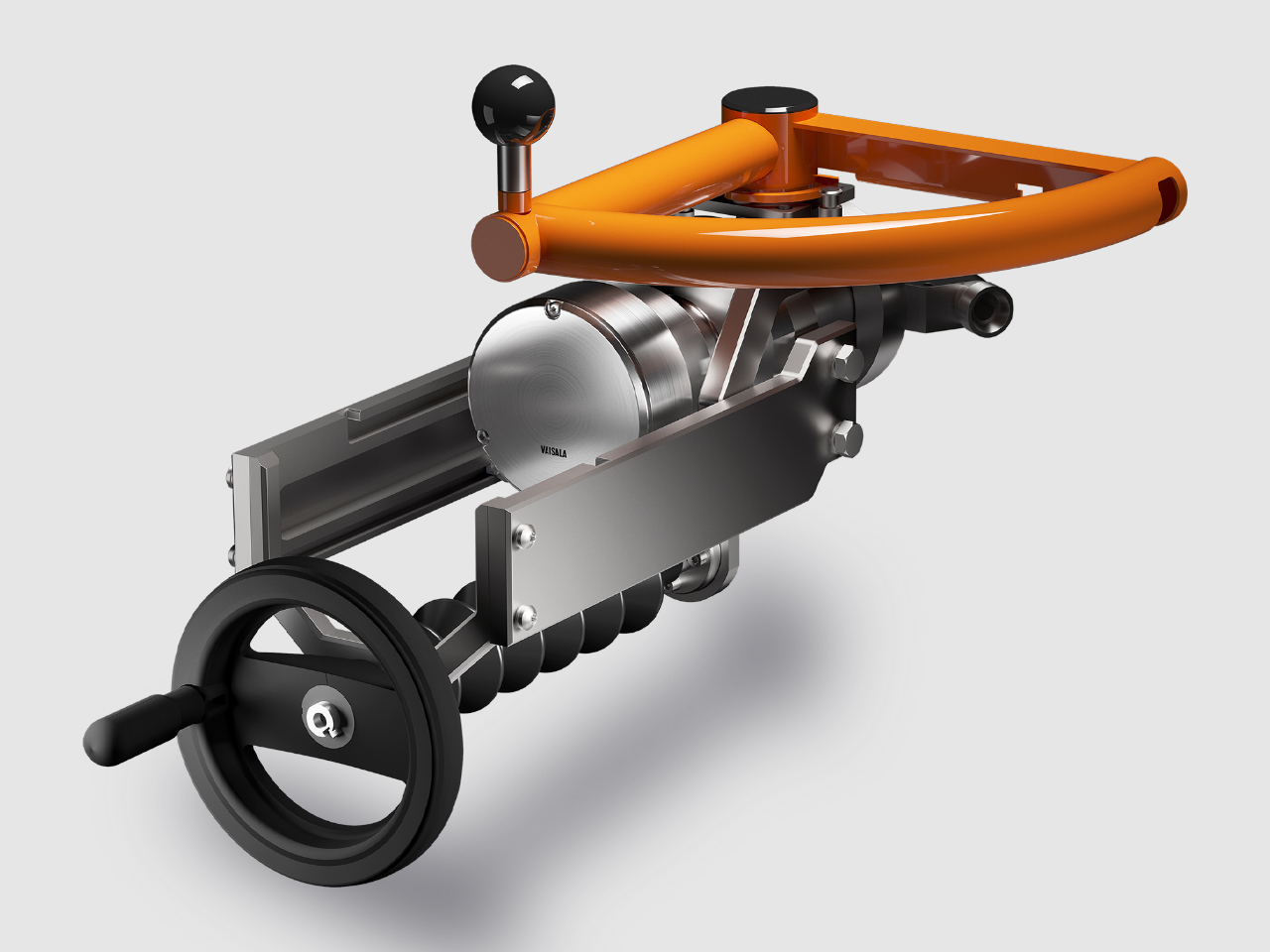

Vaisala Polaris™ PR53GP and GPEX Probe Process Refractometers for ordinary and explosive areas

Measure concentrations of sugars/Brix, acids, alkaline solutions, alcohols, hydrocarbons, solvents, and various other solutions directly in pipeline and tanks, in production transport and quality control in sugar, chemical, petrochemical, and other industries.

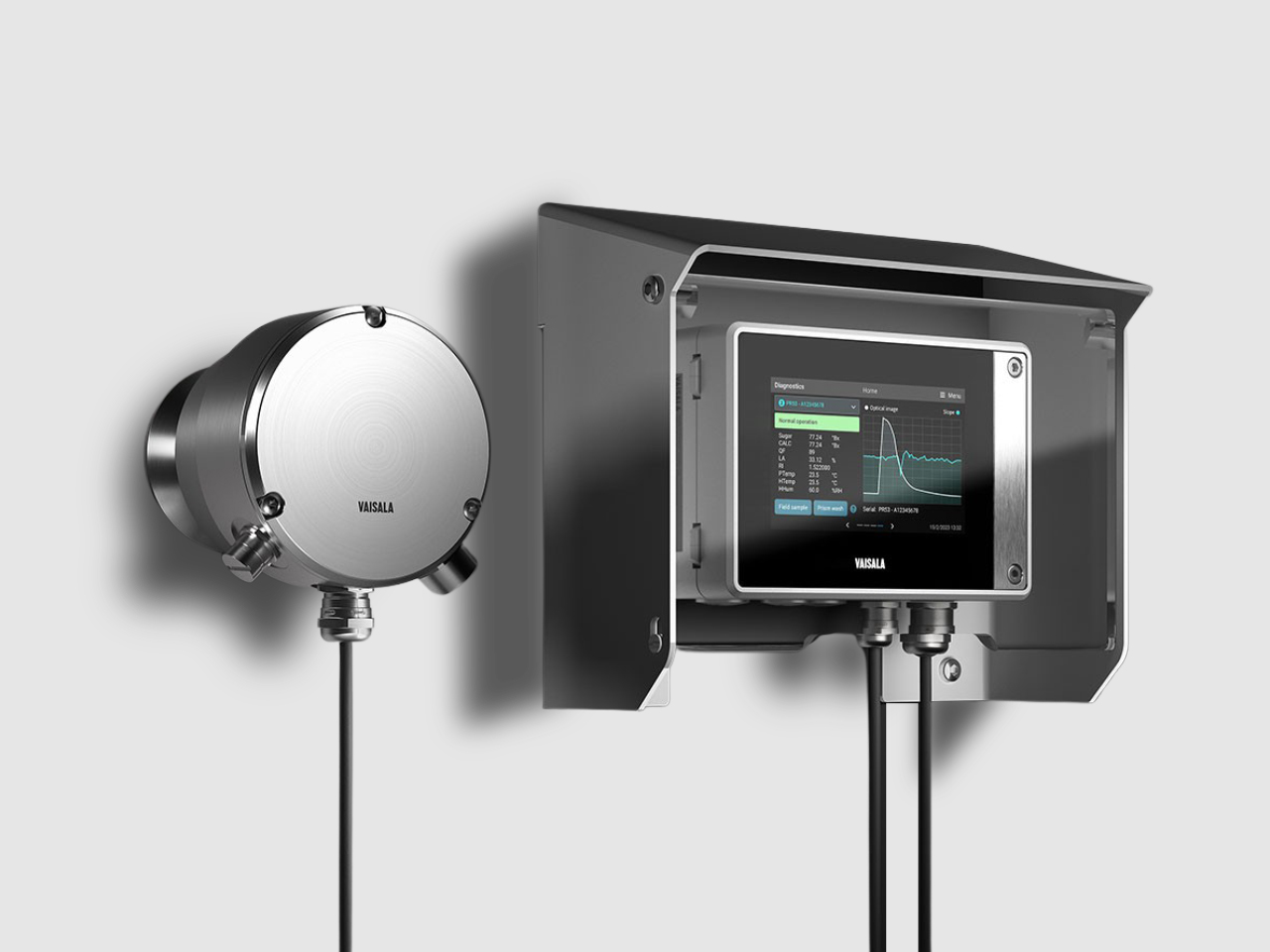

Indigo520 for process refractometers

Vaisala Polaris combined with Indigo520L offers compelling features for all users and are a standard power couple for applications and installation positions with wash system.

Kevin Green, Vaisala Industry Expert & Regional Sales Manager

Kevin has a background in Mechanical Engineering and brings many years of experience in instrumentation, sales and product management with companies such as Emerson – Rosemount Measurement, McCrometer, and ABB. At Vaisala he is primarily focused on measurement applications applied to industries such as semiconductors, food and beverage production, chemical processing, and pulp and paper manufacturing. In his spare time Kevin enjoys cycling and mountain biking, skiing, tennis, and spending time with family and friends.

Dave Lobach, Rocky Mountain Instrumentation Inc.

For over 30 years, Dave Lobach has been committed to helping clients with their manufacturing and processing applications. In his time with Rocky Mountain Instrumentation, Inc. (RMI) Dave has worked to provide cutting-edge systems for process control. Established in 1991, RMI has been at the forefront of delivering industrial instrumentation across the Intermountain West in the USA, encompassing states such as Utah, Colorado, Nevada, Idaho, Wyoming, and Montana. RMI serves client companies in various sectors, including Oil & Gas, Life Science, Metal & Mining, and Water & Wastewater. With in-depth application experience spanning over three decades, Dave has collaborated closely with industry partners to engineer solutions that meet the demands of modern industrial applications.

eBook: Liquid concentration and density measurements in industrial chemical applications

In this eBook you will learn about the two most common methods of liquid concentration measurement, i.e. refractive index (refractometer) and density (Coriolis, ultrasonic, nuclear, and microwave). We outline the advantages and disadvantages of each technology.