How refractometer prism washing in challenging applications can create a competitive advantage

Food and beverage, chemical, papermaking – all of these industries share something in common. In order to ensure safety and a high-quality end product, measuring the concentration of key substances in their liquid processes is extremely important.

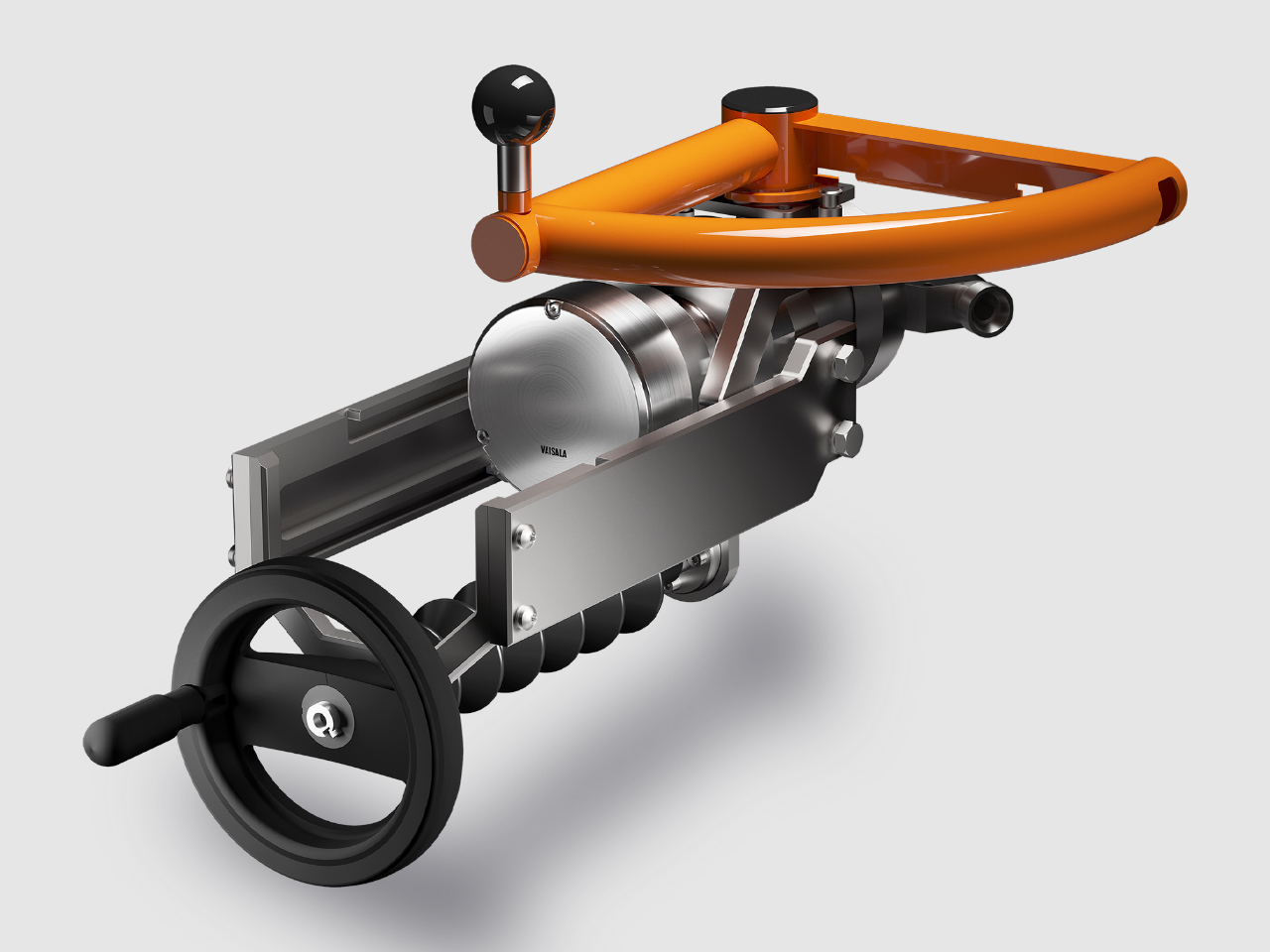

A Vaisala process refractometer gives you high-quality optical measurements of your liquid processes. With the elbow flow cell design, the flow of the fluid usually keeps the prism clean – nine times out of 10, nothing extra is needed. But in some demanding applications, a prism washing system is necessary, which we’ll look at more closely in this article.

How do I know if my application needs a prism washing system?

The chances are, it doesn’t. Vaisala process refractometers use optical measurements to measure the concentration of various solutions such as acids, alcohols, solvents, hydrocarbons, and sucrose. This can be done in almost any liquid – basically, if you can pump it, a Vaisala refractometer can measure it.

But in order for the measurement to be accurate, the prism in the refractometer needs to be free of residue. This is usually not an issue, but in some applications, the solution being measured can cause build-up on the prism. This can happen for example in the pulp and paper industry with black liquor measurement, or in the food and beverage industry with blanching of starchy foods like potatoes. As the build-up on the prism grows, it can cause the measurement values to drift, leading to inaccurate measurements. In the worst cases, measurement becomes impossible until the prism is cleaned.

What kind of prism washing systems are available?

This is where prism washing systems come into play. Vaisala offers different kinds of systems depending on your application and need. The most common is steam washing. This is exactly what it sounds like – at regular intervals (for example every 20 minutes) the prism is blasted with steam for a few seconds. The steam helps keep the prism crystal clear even in the most challenging environments.

If your application is sensitive to heat and steam can’t be used – which can happen in the chemicals, mining, or food and beverage industries for example – there is also the option of a high-pressure water system. Much like the first option, the prism is cleaned with short blasts of water at regular intervals. The wash can also be made with a suitable solvent depending on the process fluid.

Is a prism washing system expensive or difficult to install?

A prism-washing system is cost-effective and can be added to Vaisala refractometers as a retrofit. The initial investment for such a system is low, as is the operating cost as only small amounts of steam, water, or solvent are needed for washing.

While choosing the right system for your application may seem complicated, in practice it isn’t. Vaisala has decades of experience in working with liquid process measurements across a wide range of industries and our prism washing solutions are field-proven and easy to install. Our experts will help you to determine if you need a prism washing system in the first place – and if you do, will advise you on the best system for your application.

In this way, in the uncommon case where your application is too challenging to use a Vaisala refractometer as is, there is an off-the-shelf solution available to make sure your liquid process measurement is as accurate, stable and repeatable as possible. The end result is that your process – and your business – runs smoothly.

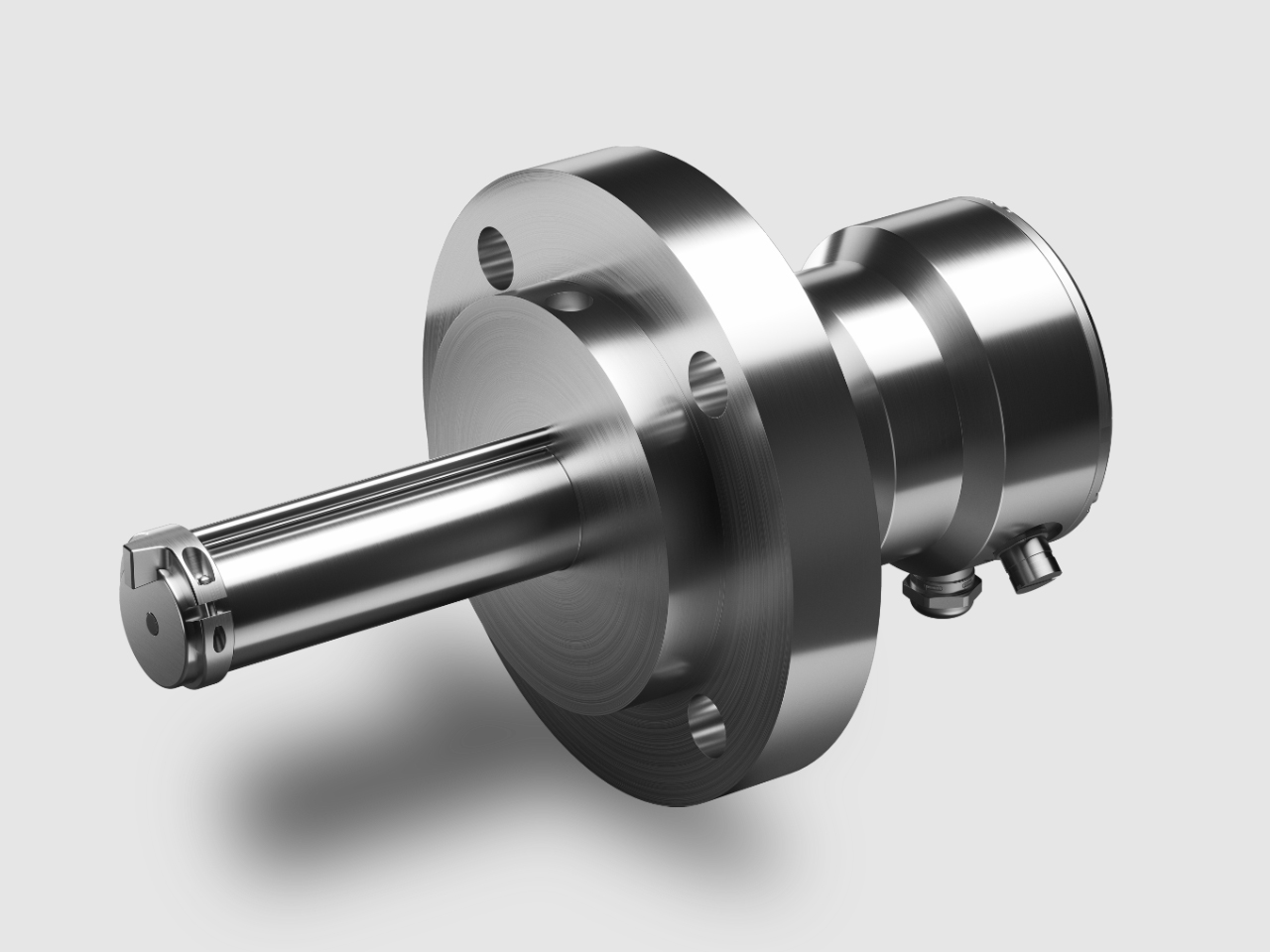

Vaisala Polaris™ PR53SD Process Refractometer

Pulp industry process optimization, black and green liquor, brown stock washing and other liquid concentrations in fiber and chemical recovery lines

Vaisala Polaris™ PR53GP and GPEX Probe Process Refractometers for ordinary and explosive areas

Measure concentrations of sugars/Brix, acids, alkaline solutions, alcohols, hydrocarbons, solvents, and various other solutions directly in pipeline and tanks, in production transport and quality control in sugar, chemical, petrochemical, and other industries.

Vaisala Polaris™ PR53GC and GCEX Compact Process Refractometers for ordinary and explosive areas

Measure concentrations of acids, alkaline solutions, alcohols, hydrocarbons, solvents and various other solutions directly in pipeline, in production transport and quality control in chemical and other industries

Vaisala Polaris™ PR53AP and APEX Sanitary Probe Process Refractometers for ordinary and explosive areas

Measure Brix and other liquid concentrations with instant productivity and material gains, and simplified process operation for food and beverage manufacturing, including OEMs.

Vaisala Polaris™ PR53AC and ACEX Sanitary Compact Process Refractometers for ordinary and explosive areas

Measure Brix and other liquid concentrations with instant productivity and material gains, and simplified process operation for food, beverage, dairy and brewery manufacturing