Warehouse monitoring & mapping

For GDP-regulated storage & distribution

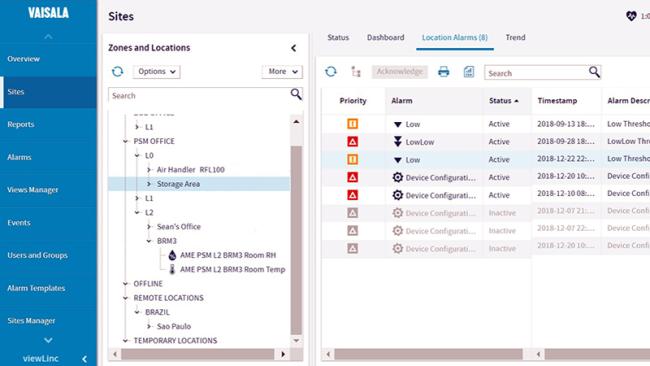

Reduce the risk of non-compliance and lost products in your life science holding and storage applications areas with the viewLinc Continuous Monitoring system:

• Easy connectivity - wired/PoE and wireless VaiNet data loggers provide connectivity for versatile installation

• 24/7 remote alarming via SMS, email, or local signal tower alerts

• Custom reports can be automated and delivered by email on demand, or scheduled

• Comprehensive IQOQ validation documents

• On-site installation/validation services available

• Indigo80 Hand-held indicators can be used for spot-checking and on-site calibrations

• Simplified warehouse mapping solutions. Save time and costs qualifying storage areas with Vaisala's Mapping kit

• Mapping services available in selected regions

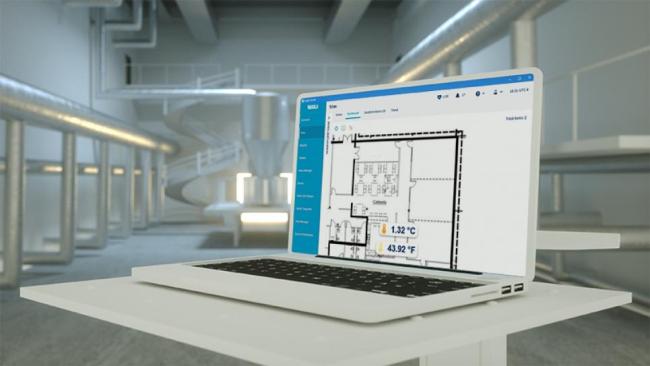

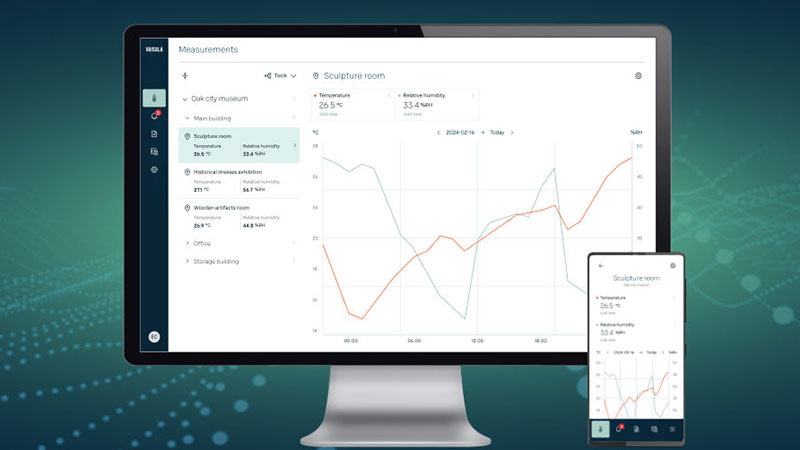

• Choose from viewLinc Enterprise Server Software for on-premises or viewLinc Cloud.

For Commercial storage & distribution

Jade Smart Cloud monitoring system ensures the quality of stored goods, such as electronics, perishable goods, food & beverage, high-quality mechanical and aerospace products and other valuable items:

• Long product lifespan minimizes the total cost of ownership

• Long-term record of measurement data for reporting on storage conditions

• Easily scalable for a variety of storage applications

• Data securely stored in the cloud, reducing IT load

• 24/7 remote alarming via SMS & email

• Superior long-range LoRa® based VaiNet radio technology for reliable monitoring

• Easy addition of new loggers and access points enables effortless system expansion

• Accurate data based on Vaisala HUMICAP® proven sensor technology

• Indigo80 Hand-held indicators can be used for spot-checking and on-site calibrations

Warehouse monitoring and mapping products

viewLinc Continuous Monitoring System (CMS)

Jade Smart Cloud

VaiNet Wireless Temperature & Humidity Data Logger RFL100

VDL200 Data Logger

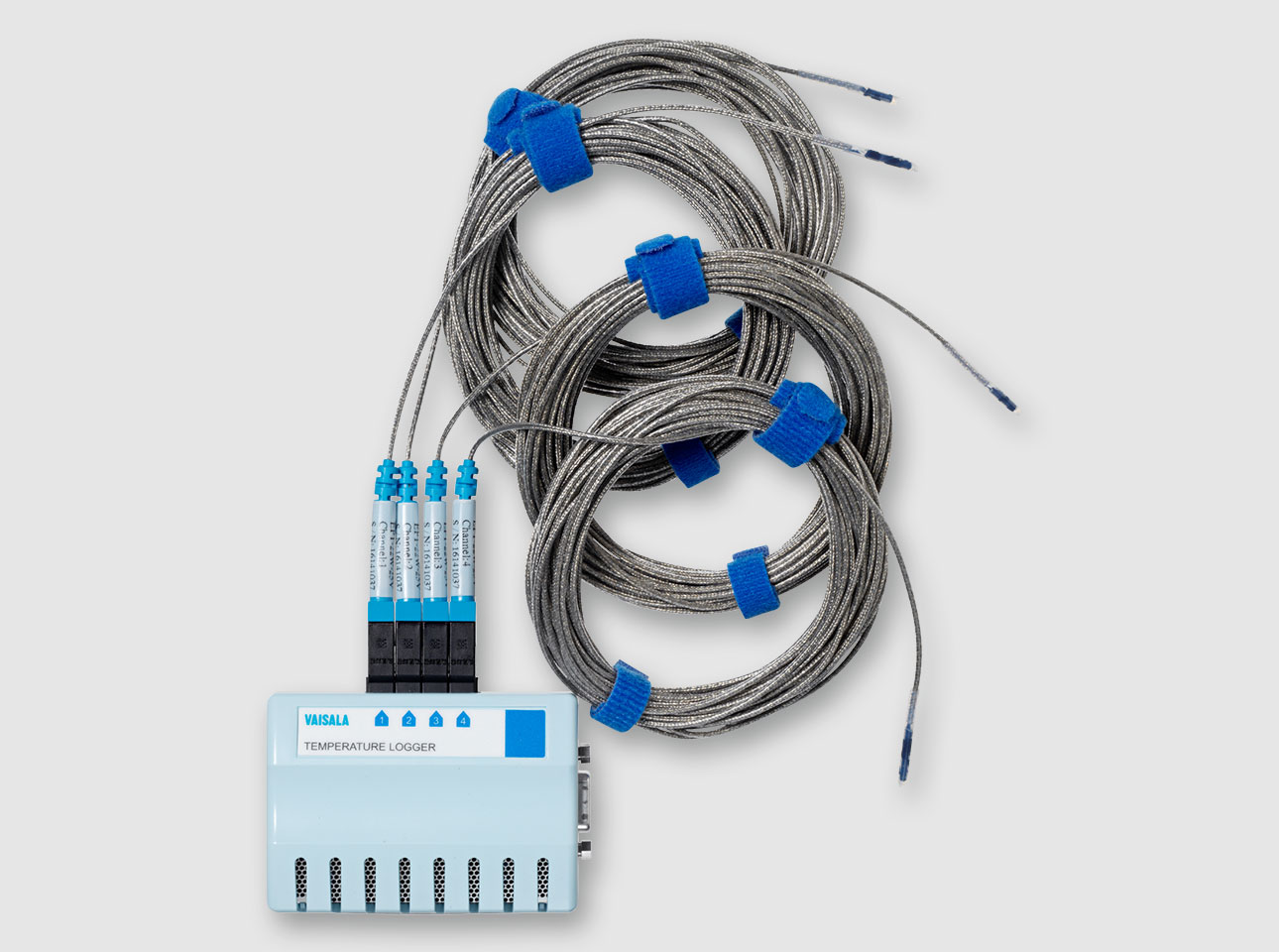

Validation mapping kit

Indigo500 Series Transmitters

Indigo200 Series Transmitters for Vaisala smart probes

Temperature Transmitters TMT120/130

Temperature and Humidity Data Loggers DL2000

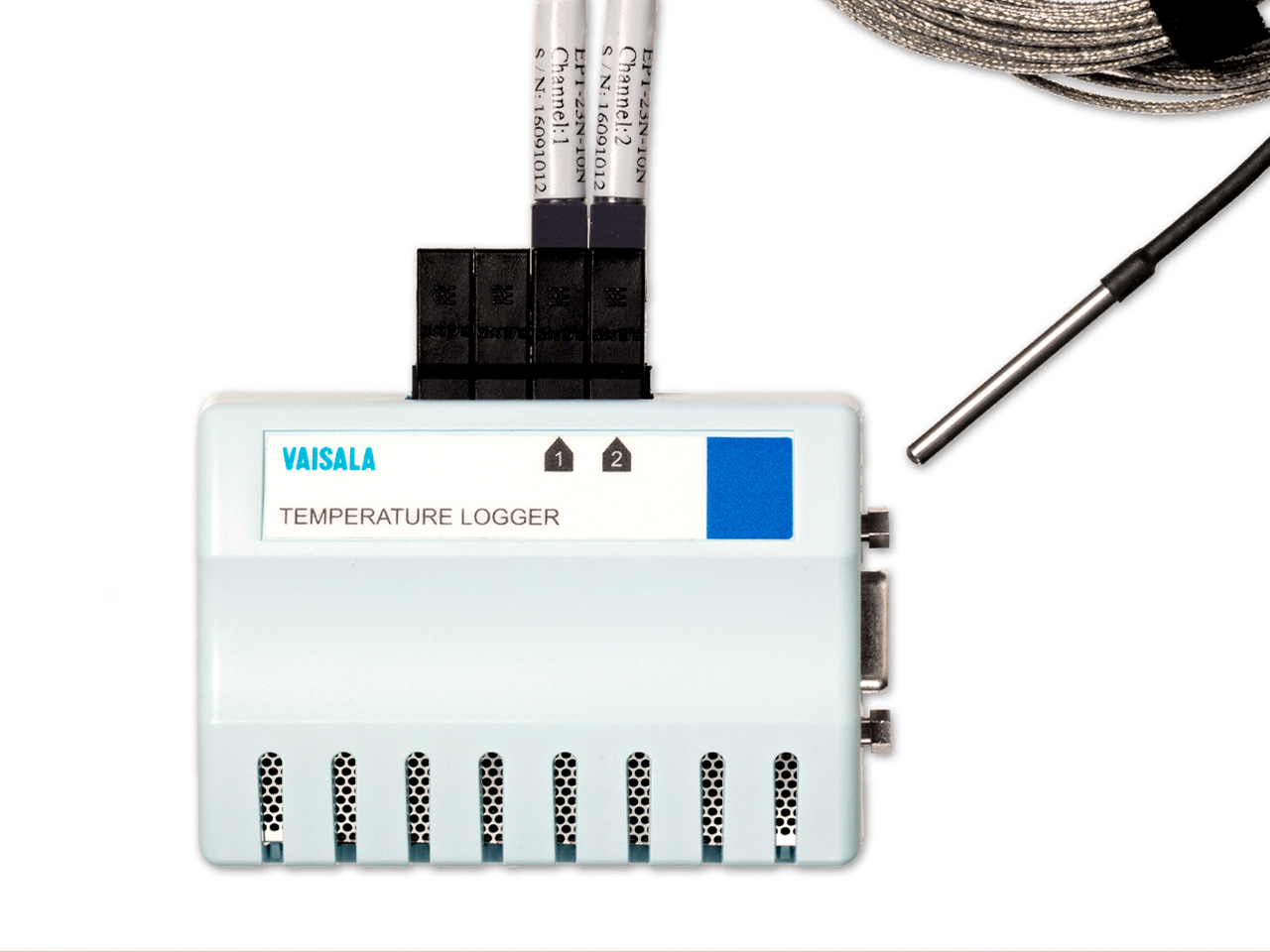

Temperature Data Loggers DL1016/1416

DL1000-1400 Temperature Logger