In this free webinar we share the key success factors for maintaining world-class measurement performance for your instruments

The webinar answers the following questions:

- What is the best way to ensure measurement quality?

- How does measurement quality affect my operations?

- How can I maintain instrument accuracy in demanding applications?

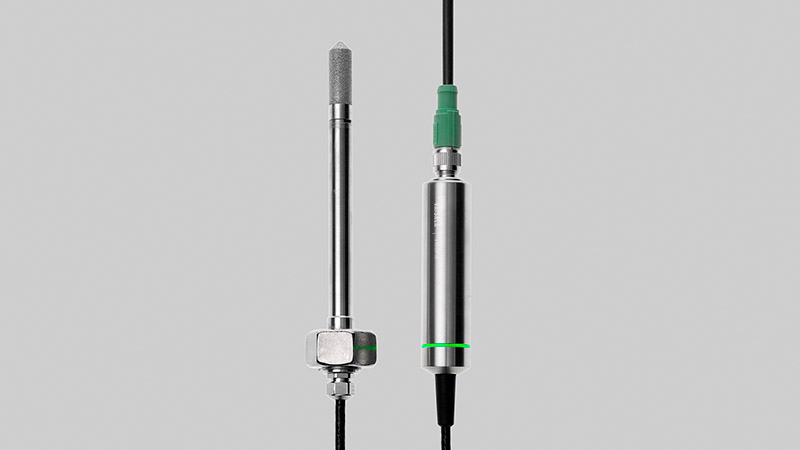

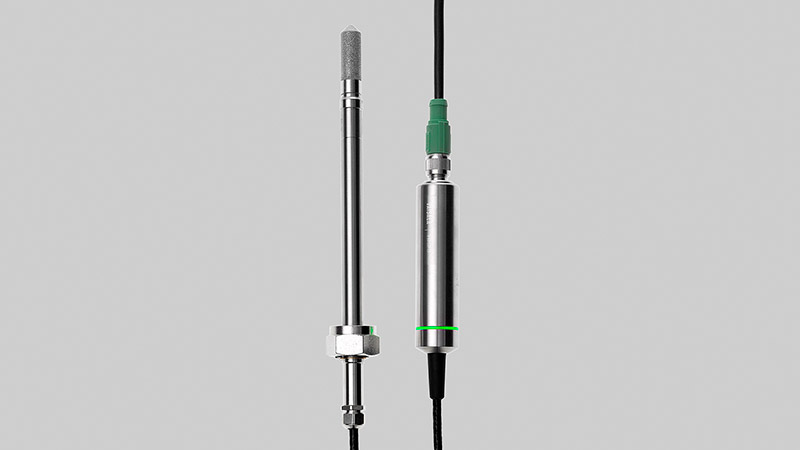

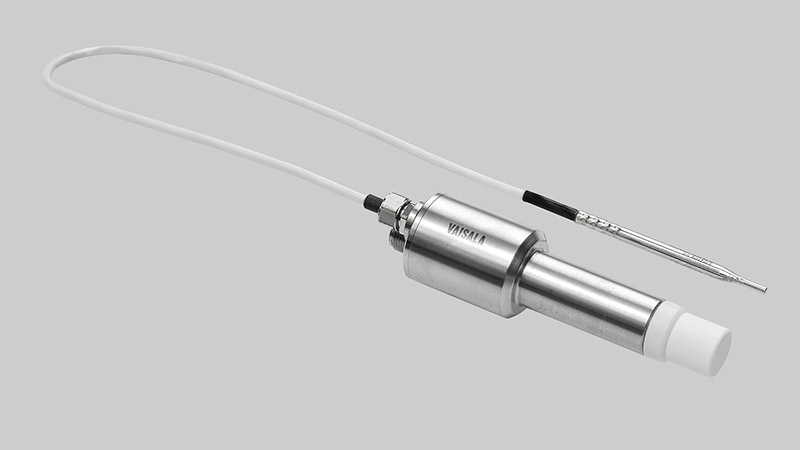

- What features help in maintaining excellent performance in high-quality measurement instruments?

- How can innovations in the latest generation of instruments make maintenance easier? Learn more about recently launched Vaisala Indigo520 Transmitter

During the webinar you learn about:

- What contributes to instrument lifecycle cost and how to minimize it

- When and how to calibrate your instruments

- The factors that determine the type and frequency of calibration you need

Who should attend?

Everybody who wants to learn more about maintaining measurement performance for your instruments.

If you already attended or registered for this webinar, please click here.

Otherwise, please register by filling the form.