Metal heat treatment furnaces

Successful metal heat treatment requires dew point measurement

Are you involved with industrial processes such as sintering, brazing, annealing or some other metallurgic process? Metal heat treatment is a complex and critical process that requires precise control of the furnace atmosphere.

The moisture content in the furnace atmosphere affects the quality and consistency of the heat treatment process, as well as the properties and performance of the final products. Therefore, it is essential to measure and control the dew point of the furnace atmosphere accurately and reliably.

What does it take to measure dew point in metal heat treatment furnaces?

Dew point is the temperature at which water vapor in a gas condenses into liquid water. It indicates how much moisture is present in a gas. A low dew point means a dry gas, while a high dew point means a moist gas. Different heat treatment processes require different dew point levels depending on the type of metal and the desired outcome.

Because of the wide variety of thermal heat treatment processes, target dew point temperatures can range from –60°C (–76°F) to elevated levels of +35°C (95°F) and even higher. Due to the extremely high oven process temperatures typically involved in heat treating, a sampling line from the furnace to the dew point probe is normally required to cool the process gas before reaching the sensor.

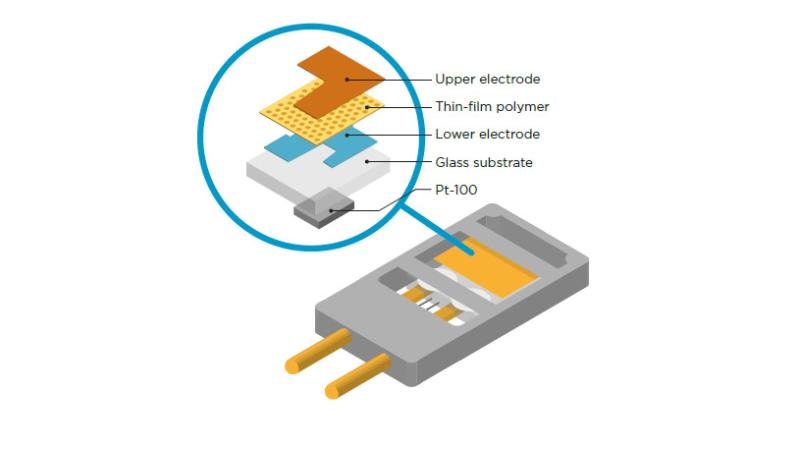

Vaisala DRYCAP®: The ultimate solution for dew point measurement in metal heat treatment applications

To measure dew point reliably in the sampling line, you need high-quality dew point measurement instruments and sample cells that can withstand the demanding conditions. They need to be leak-tight, easy to install and maintain, and compatible with various types of furnaces and gases. Moreover, the instruments provide accurate, stable, and fast readings that can be transmitted to a display or a control system.

Vaisala DRYCAP® dew point measurement instruments meet the criteria for high-quality metal heat treatment applications. Find the instrument options with DRYCAP sensor technology below.

Instruments for measuring dew point in metal heat treatment furnace sampling lines

Dew Point Probe DMP6

Dew Point and Temperature Probe DMP7

Dew Point and Temperature Probe DMP8

Insight PC Software

Indigo80 handheld measurement device

DMP80 DRYCAP® Handheld Dew Point and Temperature Probes

Indigo500 Series Transmitters

Indigo300 transmitter

Metal manufacturing measurement resources

Compressed air sampling for moisture detection

Chemicals and allied products

Acid passivation of stainless steel parts