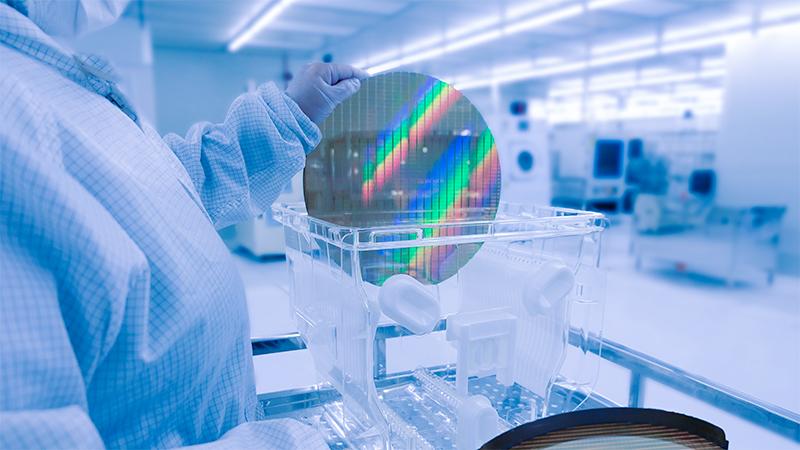

European CMP and WET Users Group Meeting

The European CMP and WET Users Group serves as an open platform for professionals engaged with these technologies in their daily work. Whether you are a process expert in device manufacturing, involved in tools and consumables, or part of the academic community, this group is your technical home. It offers a unique opportunity to expand your knowledge and build your network.

Vaisala will be present at the meeting showcasing Vaisala measurement solutions. You are welcome to have a chat.

Read more about European CMP and WET Users Group Meeting