Environmental Mapping Qualification

Vaisala offers comprehensive mapping qualification solutions to help you to comply with the GDP (Good Distribution Practice) regulations such as EU GDP (2013/C 343/01) and USP 36 Chapter <1079> and the forthcoming <1083>. Environmental mapping qualifications — necessary in areas that store human and investigational medicinal products — are performed by drug manufacturers, storage facilities, wholesale distributors and other stakeholders in the GxP supply chain.

Vaisala Environmental Mapping Qualification offerings include:

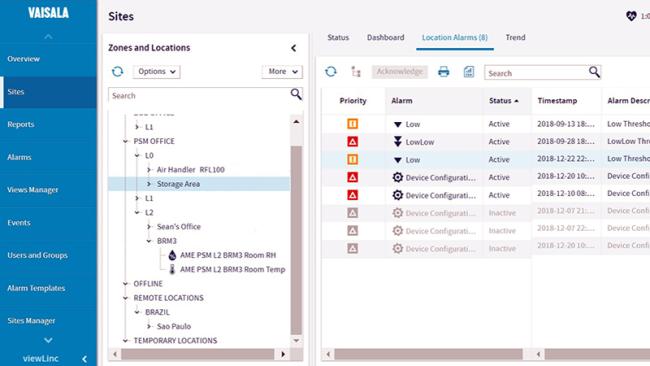

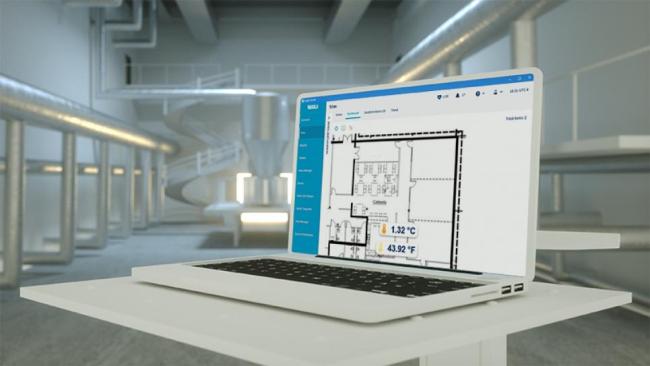

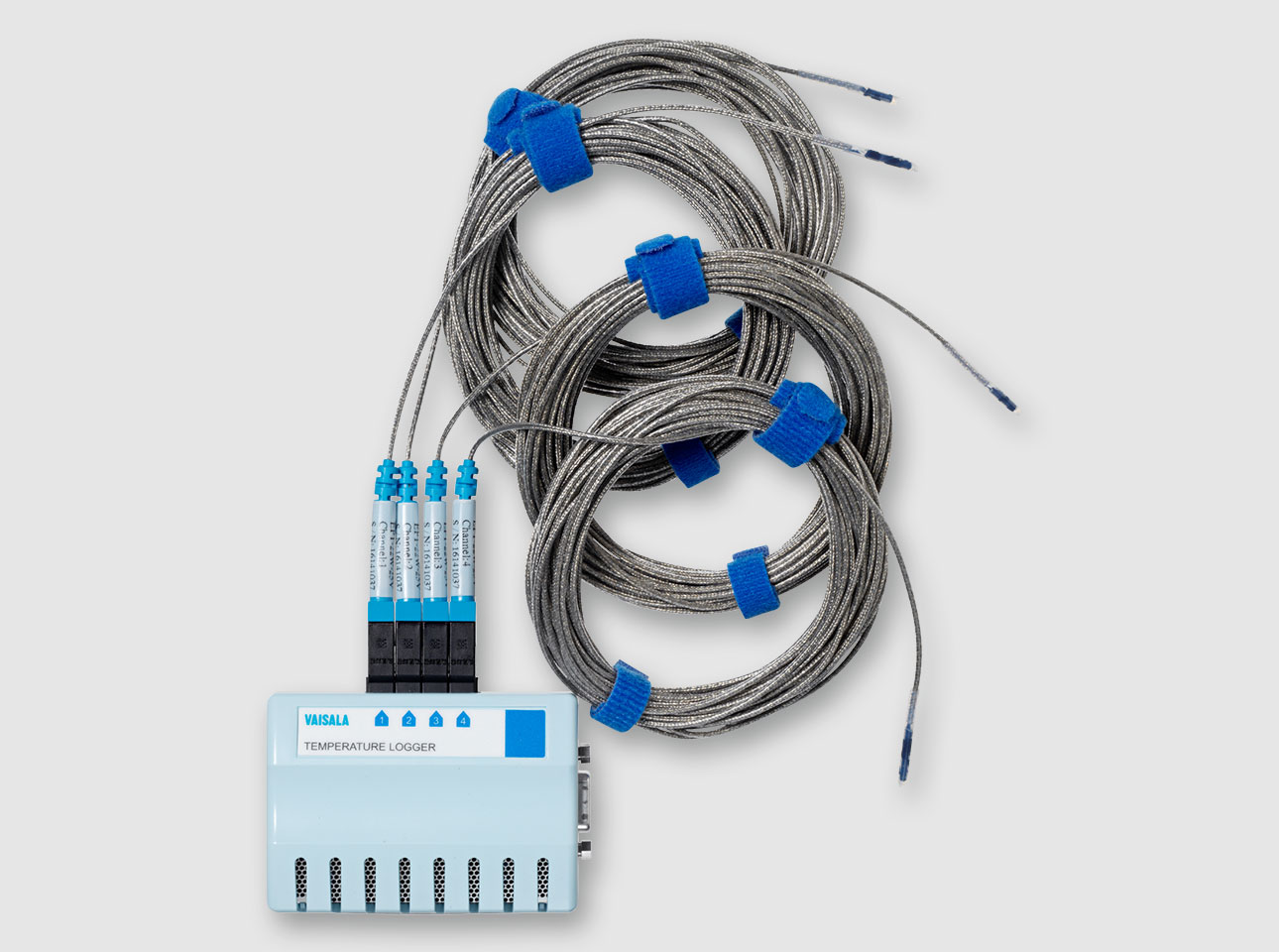

- Mapping kit: Vaisala data loggers, vLog software to collect the measurement data, and the vLog IQ/OQ protocol to validate the software according to 21 CFR Part 11 and Annex 11

- Temperature & humidity mapping services to profile the critical environmental dynamics of refrigerators, freezers, cold rooms, warehouses, storage areas, distribution centers, incubators, or stability chambers.

- Please note: This service is currently offered in Great Britain, Europe, and Japan.

- Optional custom calibration points for industry-best accuracy

Tightened Mapping Qualification Requirements, Heightened Regulatory Expectations

Good Distribution Practices have seen increased regulatory focus in the past years. This was in large part initiated by the Canadian regulatory agency Health Canada (GUI-0069, 2011), which was the first regulatory body to mention temperature mapping. This direction was soon reiterated by regulatory bodies around the globe, including:

- CDSCO (Central Drugs Standard Control Organization), India

- CFDA (China Food and Drug Administration), China

- EMA (European Medicines Agency), Europe

Each of these organizations has since published the new or updated guidelines and documents. The USA then updated USP Chapter <1079> “Good Distribution Practices for Drug Products”. Soon thereafter several guides emerged to offer specific instructions. For example, the International Society for Pharmaceutical Engineering’s cold chain management publication provides advice on the placement of mapping qualification sensors. The Parenteral Drug Association’s Technical Report 58 discusses how to perform risk assessments related to GDP. And the Pharmaceutical Inspection Co-operation Scheme released their own GDP guide, which aligns closely with EU GDP regulation. This was an important step towards global standardization as PIC/S currently has more than 40 participant countries.

Industry Changes to the Temperature-Controlled Supply Chain Drive the Need for Guidance

Meanwhile, distribution activities have evolved, and distribution chains are increasingly international. However, this has resulted in an increased risk of temperature excursions. A well-executed environmental mapping qualification is the ideal method to assess and offset the risk of excursions. But, what constitutes a well-executed mapping qualification? First, studies should always be performed before any regulated medicinal products are allowed in a cold storage area, warehouse, and temperature controlled room or chambers. Mappings should be performed under representative conditions. In practice, this means seasonal mapping studies, winter and summer. In addition, mappings should include empty and loaded conditions. Once mapping qualifications have been performed for an area or chamber, the monitoring sensors are then placed according to the locations where the most temperature fluctuation occurred - often called hot and cold spots.

The Principles of Validation Lead to Objective-based Qualifications

The ultimate goals of the environmental mapping qualification can be summarized like so:

- To demonstrate temperature (and humidity, when needed) uniformity.

- To identify unsuitable storage areas.

- To determine representative monitoring points

It’s important to remember that mapping qualification studies are not restricted to fixed places. For temperature controlled vehicles in the distribution chain, the original temperature mapping qualification is performed according to the fundamentals outlined above: under representative conditions, loaded and unloaded, with areas either excluded as a storage location or monitored continuously according to the results of the study.

For more information on Vaisala’s Environmental Mapping Qualification solutions, please see our brochure, or contact your local service center.

Resources

- EU GDP (2013/C 343/01) Guidelines of 5 November 2013 on Good Distribution Practice of medicinal products for human use

- USP 36 – Chapter <1179> Good Storage and Distribution Practices for Drug Products

- USP 36 – Chapter <1083> Good Distribution Practices (to be released in the future)

- 21 CRF Part 11 Electronic Records / Electronic Signatures

- EU GMP Annex 11 Computerized systems

- GUI- 0069 Guidelines for Temperature Control of Drug Products during Storage and Transportation, 2011.

- CDSCO Guidelines on Good Distribution practices for biological products, 2012.

- CFDA The Good Supply Practice for Pharmaceutical Products, GSP (China) Order of the Ministry of Health of the People’s Republic of China No. 90, 2013.

- ISPE Good Practice Guide – Cold Chain Management, 2011.

- PDA: Technical Report 58 – Risk Management for Temperature Controlled Distribution, 2012.

- PIC/S guide to good distribution practice for medicinal products, 2014.

Further Reading

- French standard, AFNOR NFx15-140

- Australian Standard AS2853-1986

- German Standard DIN 12880.

- Temperature mapping of storage areas, Technical supplement to WHO Technical Report Series, No. 961, 2011, Annex 9: Model guidance for the storage and transport of time and temperature–sensitive pharmaceutical products, January 2014.

- Qualification of temperature-controlled storage areas, Technical supplement to WHO Technical Report Series, No. 961, 2011, Annex 9: Model guidance for the storage and transport of time and temperature–sensitive pharmaceutical products, January 2014.

Environmental Mapping Qualification Related Products

Validation mapping kit

Temperature and Humidity Data Loggers DL2000

Temperature Data Loggers DL1016/1416

VaiNet Wireless Temperature Data Logger RFL100