In this 20-minute technical webinar, Vaisala experts Maria Nyman and Bea Siuro walk through key stages of the lead-acid battery production process and explain how to stabilize these critical processes, eliminate manual sampling, and improve overall battery yield.

The session is in 2 sections:

- the curing process, and the condensation challenge

- acid formation & filling, and the sampling challenge

Why you should attend:

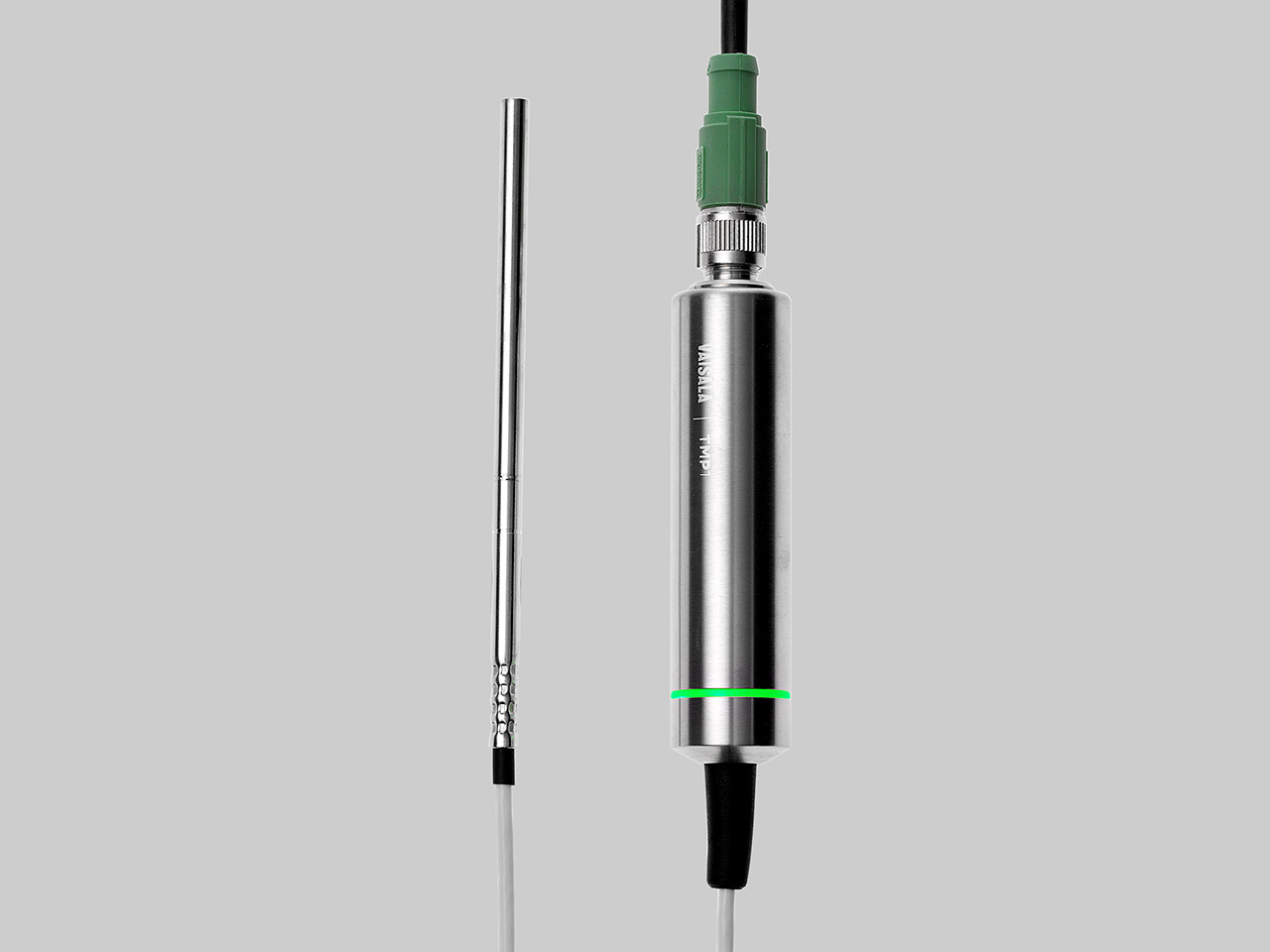

- Learn how to prevent condensation-related measurement failures and data loss in extreme process conditions: Discover why standard sensors fail in high-humidity curing chambers (90–98%rh) and how Vaisala's technology excels in these conditions.

- Fully utilize chambers and reduce production costs: Hear strategies to lower energy consumption and reduce downtime, natural gas, and water usage by switching to non-drift, maintenance-free measurement tools.

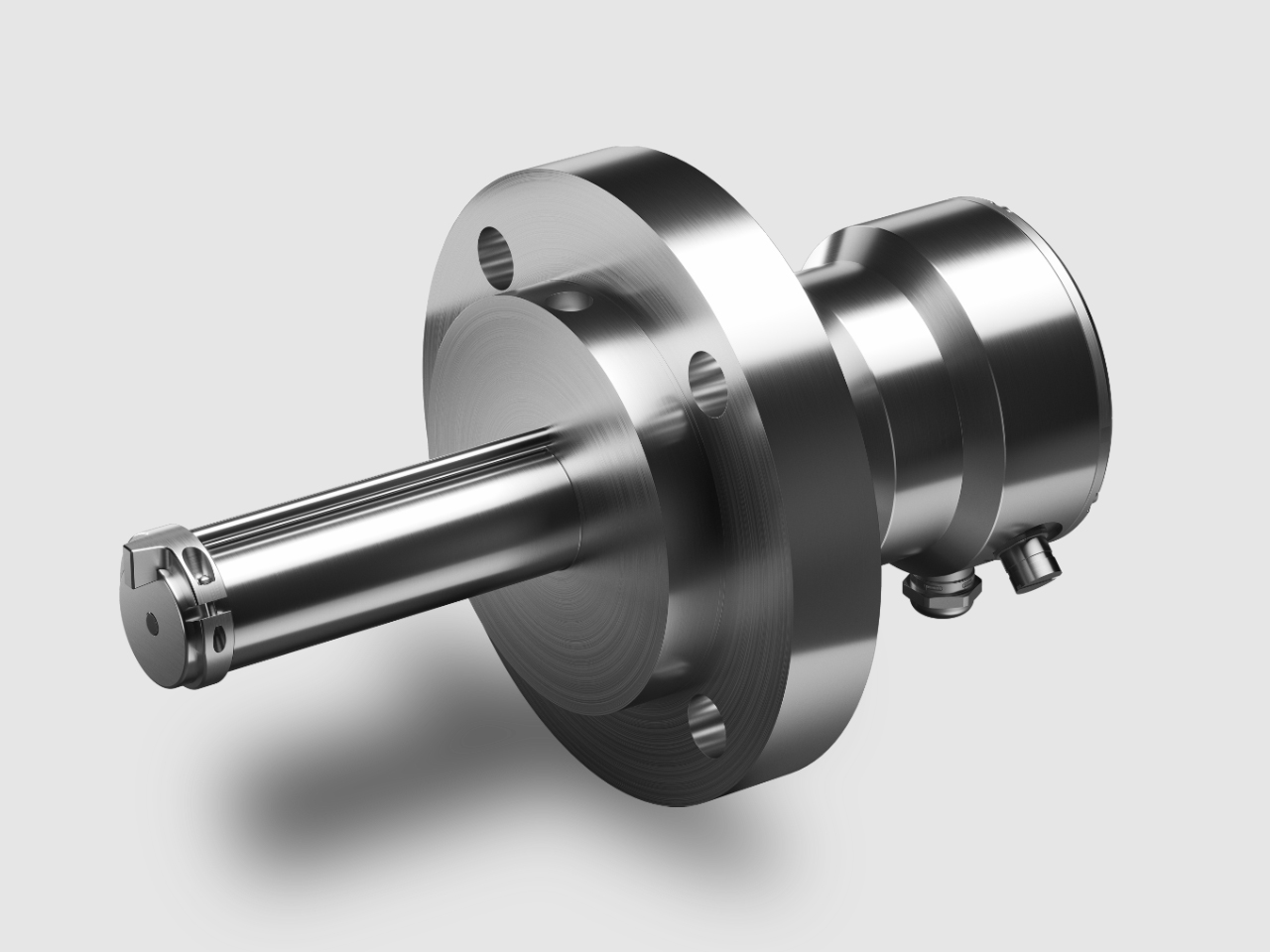

- Eliminate manual sampling, enable automation: Learn how to replace hazardous and slow manual acid checks with inline Polaris refractometers that provide real-time concentration data.

- Maximize battery lifespan: Understand the direct correlation between precise acid density (30–38%) and the electrochemical performance of the final battery. Measure sulfuric acid concentration inline and in real time across dilution, formation, and filling.

- Optimize plate quality, lead formation, and load permeation with fast, reliable measurements.

_________________________________________________________________

Who should attend?

This webinar is ideal for:

- Production and process engineers in lead‑acid battery plants

- Quality and operations managers seeking higher consistency and yield

- Plant managers looking to reduce energy, water, and acid waste

- Anyone responsible for optimizing curing, formation, or filling processes