Ignite the full potential of your process control and enhance product quality with the pioneering optical inline process refractometer product family Vaisala Polaris™

Harsh chemicals, sticky sugars and syrups, extreme temperatures, and corrosive acids. Industrial processes involving liquids are no place for fragile, unreliable, hard-to-maintain measurement equipment. And when you throw tight tolerances and high hygiene requirements into the mix, it’s easy to see why picking the right measurement technology is a must. In this blog we take a look at Vaisala’s latest-generation process refractometer platform, designed to optimize your processes, save resources, energy, and time, and enhance productivity and product quality.

Whether you’re manufacturing food and drinks, sugar, pharmaceuticals, chemicals or wood pulp, reliable and stable inline measurement of liquid concentrations is a must to ensure quality, safety, and compliance. To do this, many process industry operators rely on refractometer technology – an accurate, reliable and repeatable method that uses refractive index (RI), a property of light, to measure liquid concentrations directly from process lines.

And now a new era is beginning with the launch of the Vaisala Polaris modular process refractometer platform. Let’s take a closer look at this next-generation technology and what it has to offer in a variety of industrial measurement applications.

Building on four decades of continuous refinement

Part of the Vaisala family since 2019, K-PATENTS has over 40 years’ experience of developing industrial process refractometers for a huge variety of applications. The 5th generation, modern Vaisala Polaris products builds on this with Vaisala’s vast application knowledge and world-leading measurement instrument solutions.

The Vaisala Polaris product family products are designed to work seamlessly out of the box with Vaisala’s Indigo520 transmitters for process refractometers and are available with just three days lead time for products with standard specifications. The instruments’ measurements are based on Vaisala’s library of over 500 concentration models for accurate measurements of different dissolved solids. You can learn more about the technology and the measurement principle here.

Digital measurement’s advantage over competing analog solutions is that it is not based on aggregate readings, which can miss irregularities, but on continuous, uninterrupted readings. Furthermore, they can be installed inline in virtually any industrial process to enable real-time measurement of process conditions, eliminating the need for time-consuming lab-based measurement.

Satisfying the appetite for safe, high-quality food and drinks

Measurement equipment used in food and beverage production has to comply with a long list of tough requirements designed to protect the safety and hygiene of the manufacturing process and end product. At the same time, the process environments can be tough on equipment, with high temperatures, viscous and sticky substances, and rapidly changing conditions being common.

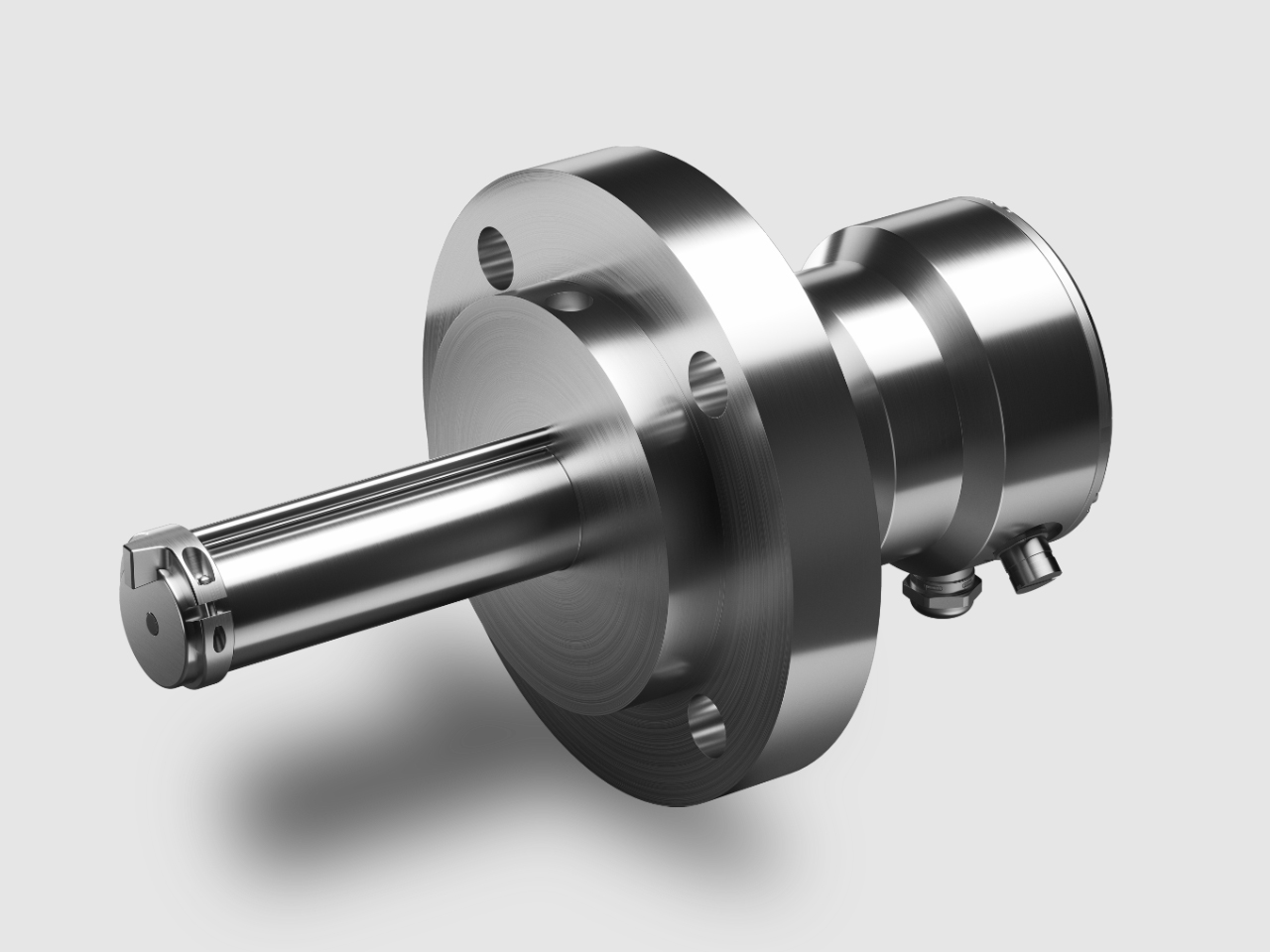

The ability to continuously monitor liquid concentrations reliably and in real time has benefits along the entire production chain, from raw-material intake to final product processing and waste-stream control. The Vaisala Polaris family includes two sanitary models specifically designed for food and beverage applications: the compact Vaisala Polaris™ PR53AC process refractometer and the long-probe Vaisala Polaris™ PR53AP process refractometer.

The PR53AC is designed for food, beverage, dairy, and brewery industry customers to measure liquid concentrations such as Brix, sucrose, gelatin and hydrogen peroxide in pipelines. It comes with 3-A and EHEDG certifications, guaranteeing that all hygiene demands are met and the product is safe to use in food and beverage processing.

The right chemical formula for fast, accurate, safe measurement

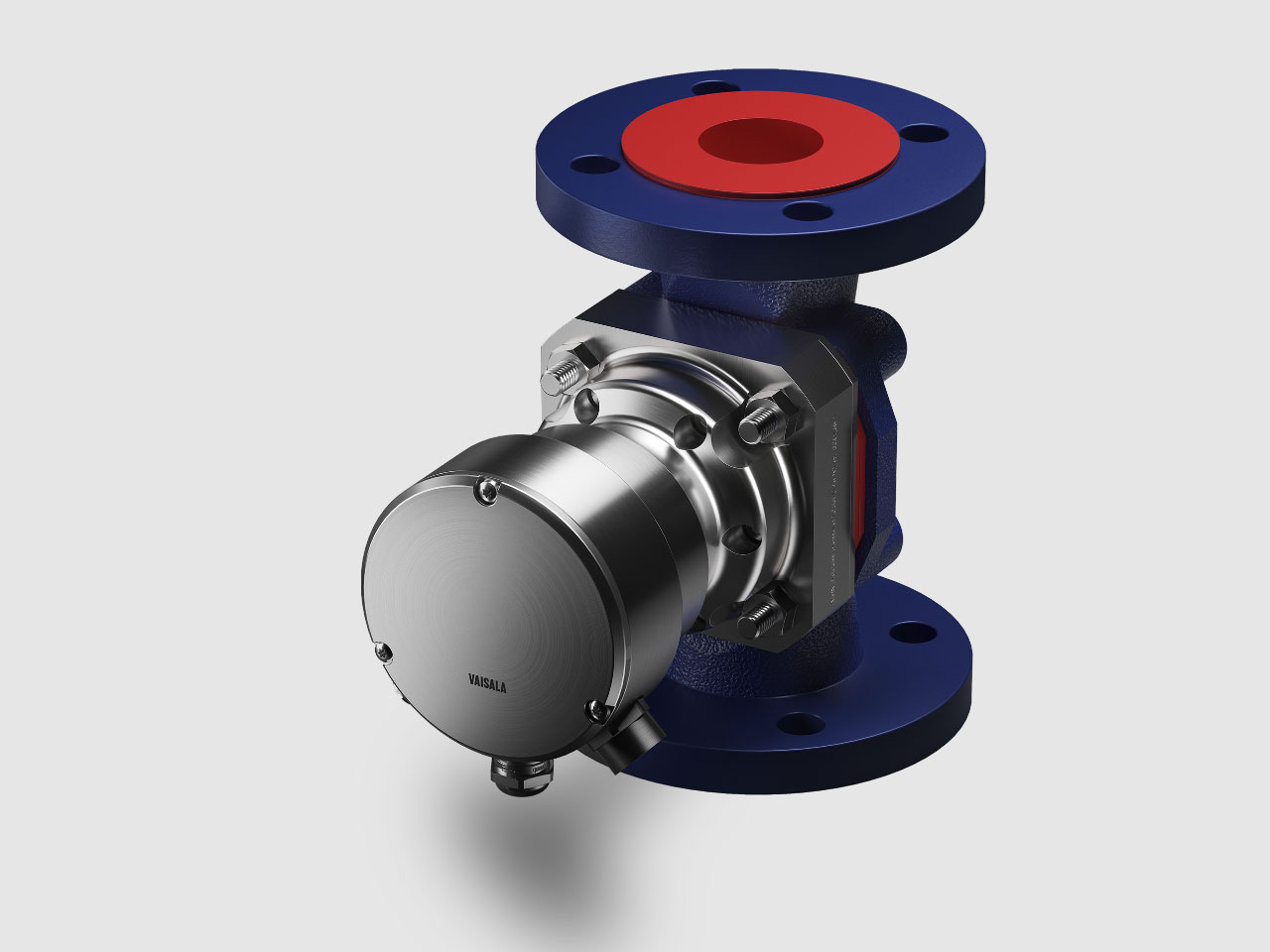

Any industrial application where chemicals are involved demands a great deal from measurement equipment. Aggressive, toxic, and corrosive chemicals often combined with high temperatures make for a highly challenging environment, while carefully balanced processes cannot tolerate contamination caused by measurement equipment materials.

The ability to measure concentrations of acids, alkalis, alcohols, hydrocarbons, solvents, and other solutions directly in pipelines and tanks during production and transport improves safety and means valuable process data can be gathered instantly instead of waiting on the results of laboratory samples.

For chemical manufacturing, petrochemical processing, and other industries where toxic and corrosive solutions are commonplace, the Vaisala Polaris family includes the Vaisala Polaris™ PR53GC, Vaisala Polaris™ PR53GP and Vaisala Polaris ™PR53M process refractometer models.

Improving safety, efficiency, and quality in wood pulp manufacturing

Just like chemical manufacturing plants, pulp mills are home to processes that use highly toxic chemicals and high temperatures and process pressures. Maintaining process efficiency and uptime are critical to profitability because shutdowns to maintain, replace, or remove measurement equipment mean lost revenue.

Furthermore, pulp manufacturing involves liquids that vary greatly in terms of both consistency and composition. Process liquids like pulp slurry and filtrates are a mixture of inorganic cooking chemicals and dissolved organic material, which can make accurate measurement challenging.

In the brown stock washing phase, wash water and weak black liquor are separated from the pulp fibers. Washing contributes to both the overall efficiency of the mill and product quality so accurate measurement of pulp cleanliness is critical. It can help avoid excessive water and energy consumption and expense, and lead to better chemical recovery, lower bleaching costs, and improved pulp consistency.

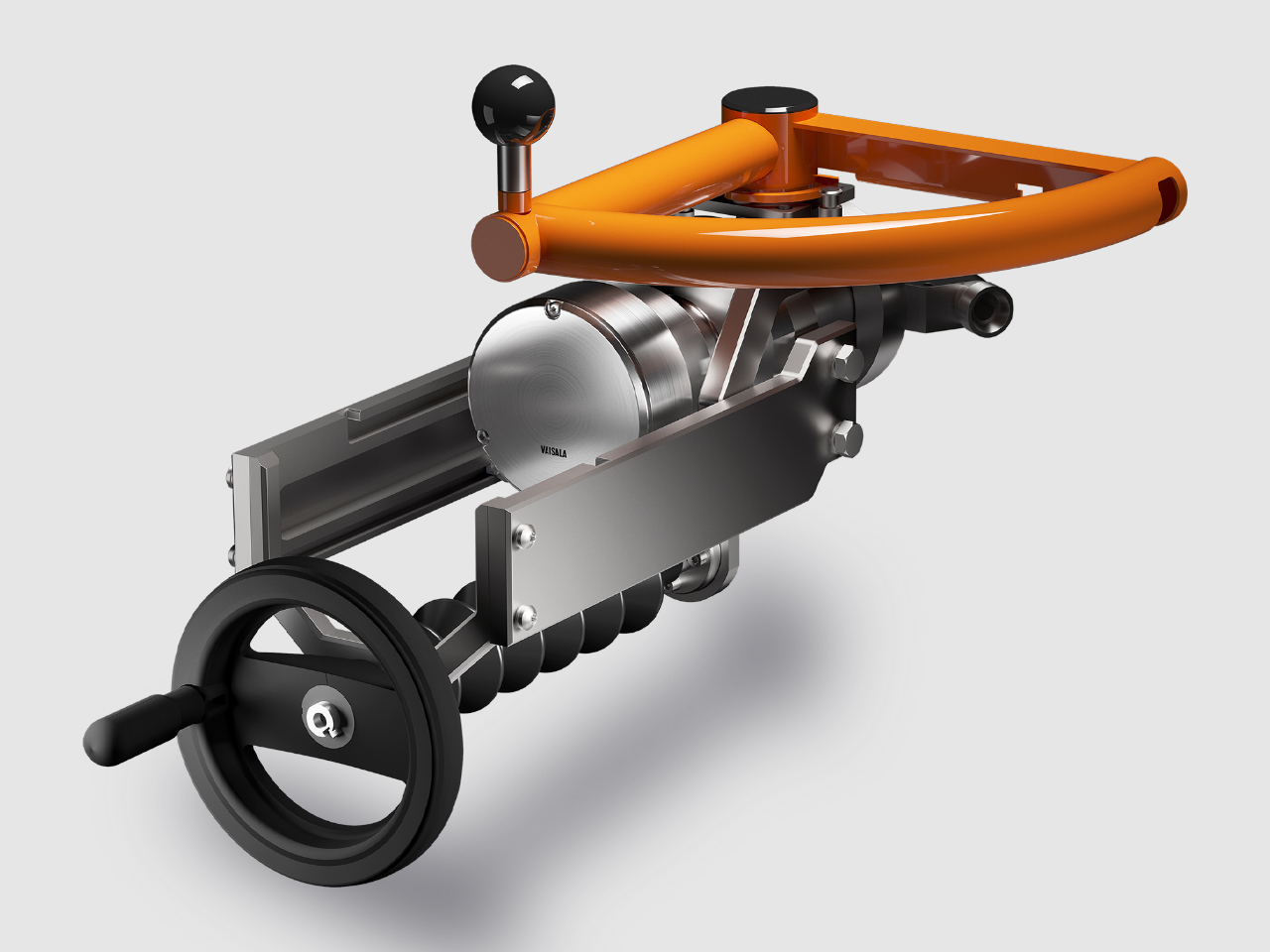

Vaisala’s answer to these challenges is the Vaisala Polaris™ PR53SD process refractometer, which is designed for measuring total dissolved solids and other concentrations in pulp mill fiber and chemical recovery lines. The SAFE-DRIVE retractor system allows the refractometer to be inserted and removed while the process is running, eliminating the need to disturb the process to take measurements.

The SAFE-DRIVE system has been developed to increase safety for operators and to withstand the extreme process conditions of pulp production, with a simple operating principle preventing inadvertent errors in use. The retractable refractometer, designed especially for green liquor applications, and the retractable wash nozzle are both unique in the market.

The refractive index measurement is sensitive to both organic and inorganic fractions in process liquids and reacts to process variations immediately, and the data gathered can be used for real-time process optimization. In black liquor applications, where liquor is concentrated for energy recovery in a boiler, total dissolved solids up to 85% can be measured directly inline regardless of liquor consistency, rapidly changing process conditions, or the presence of particles or fibers.

The Vaisala Polaris PR53SD is available with a choice of field-proven wash systems to enable reliable measurement in fiber line, brown stock washing, evaporation, black liquor firing, slaker, and lime operations.

A sweeter deal for sugar and sweetener manufacturing

In sugar and sweetener manufacturing accurate liquid concentration measurement has a critical role to play in enhancing the energy efficiency of the manufacturing process and the quality of the final product. High ambient and process temperatures are common in these processes, meaning measurement equipment needs to be robust enough to withstand the conditions.

The Vaisala Polaris PR53GP and Vaisala Polaris PR53AP process refractometers are an ideal choice for these applications. They include a special vertical detection algorithm for sugar crystallization to enable accurate mother liquor concentration measurements during crystallization strikes, especially when crystals are forming, and offer the full measurement range from 0–100 Brix.

The Vaisala Polaris PR53GP and Vaisala Polaris PR53AP enable reliable concentration control via accurate Brix, total concentration, and supersaturation measurement in starch sweetener and sugar substitute manufacturing, including glucose (dextrose), fructose glucose syrup, corn syrup, and sorbitol.

Comment

Add new comment