How Inline Refractive Index Measurement Enhances Filter Cake Washing & Process Control

This article is the third in our three-part series on how Vaisala refractometers help optimize API manufacturing. The first installment explored solvent swap optimization using refractive index (RI) trend data, and the second covered crystallization control with RI.

In many API facilities, filter cake washing is a process bottleneck. After crystallization, the API must be separated from the liquid phase and cleaned—typically by washing the filter cake with a solvent. The aim is straightforward: remove residual mother liquor from the crystals to obtain a pure product, without sacrificing yield. The challenge lies in optimizing the solvent amount—enough to achieve purity, but not so much that it wastes time, materials, or product.

Refractive Index as a PAT Tool

RI measurement supports a Quality by Design approach by helping identify critical process parameters:

- What type of wash should be used?

- How much solvent is required?

- Which parameters most influence quality and yield?

During development, RI can also compare solvents to find one that both washes effectively and minimizes API solubility.

Case Study: Data-Driven Solvent Optimization

One Vaisala customer used RI to evaluate their washing performance and determine if a process control tool was truly necessary. In the lab, a Vaisala refractometer measured liquid concentration after washing, while a scale recorded solvent usage. Plotting solvent volume against RI produced a clear process profile:

- Displacement phase: RI remains constant as mother liquor is pushed out.

- Mixing phase: RI changes as washing solvent removes residual impurities.

- Completion phase: RI stabilizes, signaling the end of effective washing.

The team also tested different solvents, measuring each one’s RI in both clean and API-saturated states. This revealed whether washing was ending with truly clean solvent—or with solvent already near saturation, risking product loss.

Key Findings

- Low-solubility solvent: Ineffective washing; crystals not fully cleaned.

- High-solubility solvent: Dissolution of fine particles, creating preferential channels and inefficient wash.

- RI data confirmed that solvent choice could either protect yield or cause product loss.

Outcome

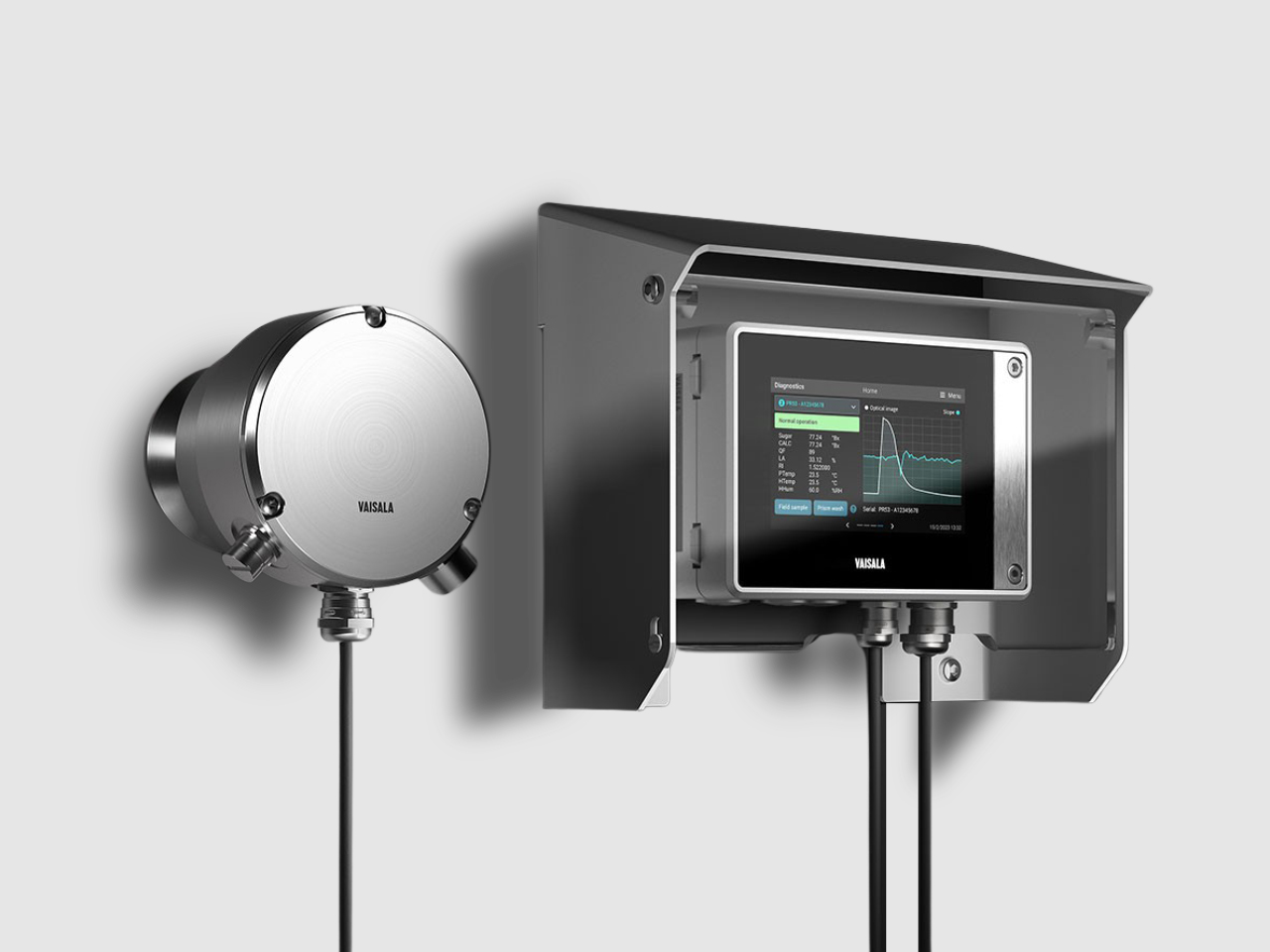

These tests formed a solid proof of concept, enabling the customer to advance efficiently to pilot scale. They concluded that RI is a valuable, reproducible, and data-rich tool for optimizing filter cake washing—not only in laboratory process development and scale-up, but also as a real-time control tool in manufacturing. By monitoring when the RI measurement becomes stable, operators can confidently determine when washing is complete, reducing unnecessary solvent use and process time by avoiding overflushing. Vaisala refractometers thus support both data-driven process optimization and efficient, validated process control.

To learn more about refractive index measurements to optimize filter cake washing, see our application note.

Add new comment