Application Note:

Wet Process Phosphoric Acid

Typical end products

Phosphoric acid is used in a wide range of industrial applications, including the manufacture of:

- Agricultural phosphate fertilizers

- Detergents

- Pesticides

- Metal coatings

- Food additives

- Beverages

- Pharmaceuticals

- Dental products

- Cosmetics and skincare

Introduction

Phosphoric acid (H₃PO₄) is a key industrial chemical with a wide range of applications. While it is most commonly associated with phosphate fertilizer production, its mildly acidic and non-toxic properties also make it valuable in the food, beverage, pharmaceutical, and cosmetics industries.

The most prevalent method for producing phosphoric acid is the wet process, in which phosphate rock reacts with sulfuric acid (H₂SO₄) to yield phosphoric acid (H₃PO₄) and gypsum as a byproduct.

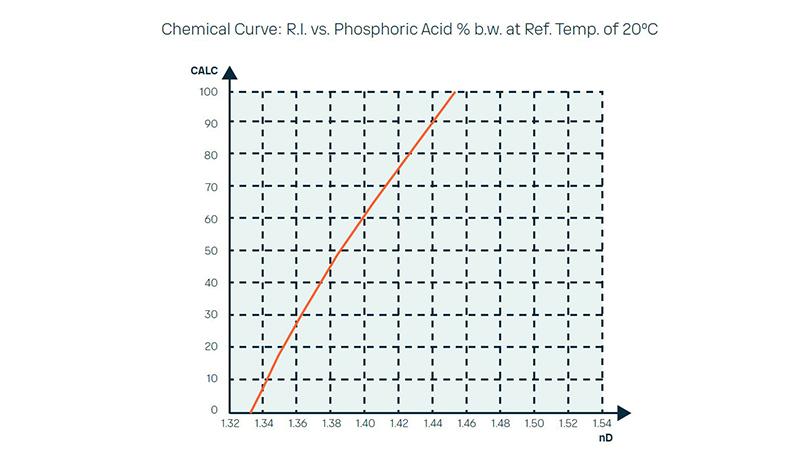

Phosphoric acid concentration is typically expressed as phosphoric anhydride (% P₂O₅) rather than as H₃PO₄. The two primary grades are:

- Commercial (merchant) grade: 40–54% P₂O₅

- High grade: 75–85% P₂O₅

Wet Process Overview

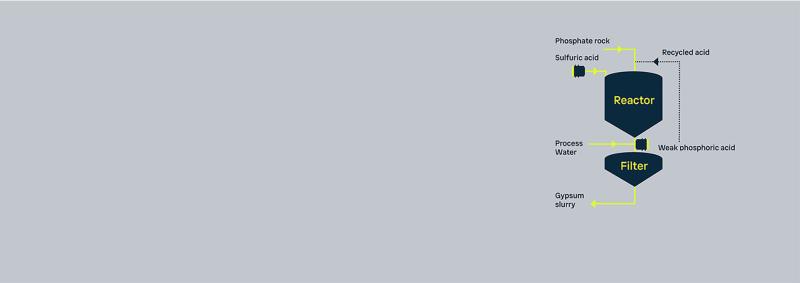

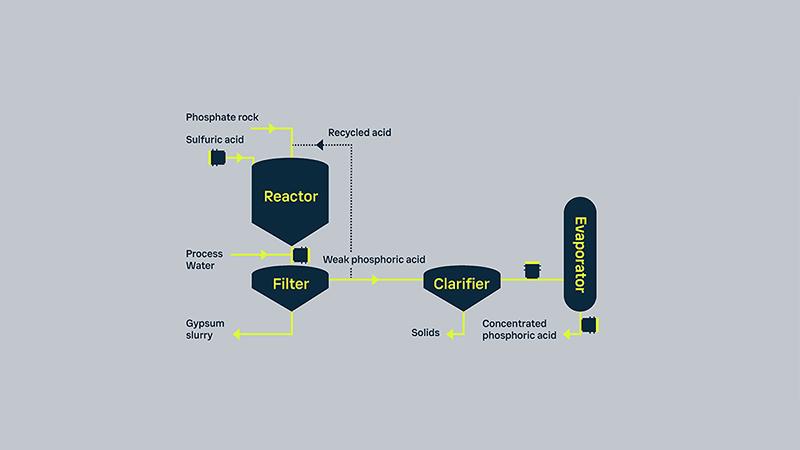

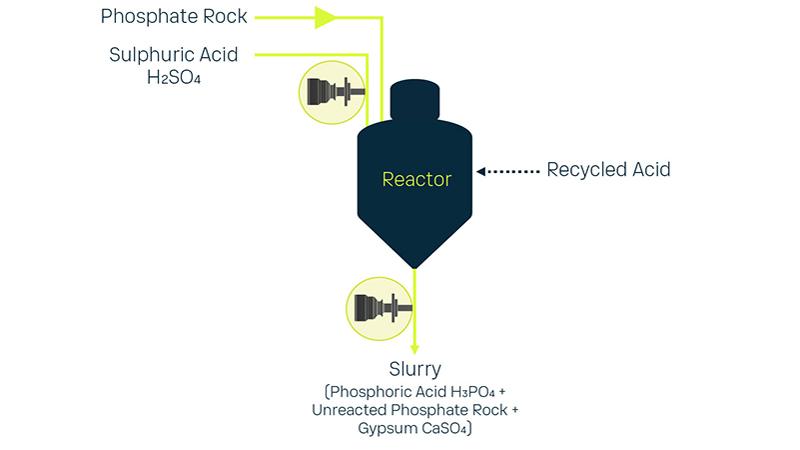

The wet process involves three primary steps: reaction, filtration, and concentration.

Reaction:

Phosphate rock is first ground and fed into a reactor, where it reacts with sulfuric acid. This step is known as acidulation. During this reaction, tricalcium phosphate from the rock is converted into phosphoric acid and calcium sulfate (CaSO₄) — commonly known as gypsum.Maintaining sulfuric acid concentration between 93–98% is critical for optimal process performance. It ensures effective dissolution of phosphate rock, promotes proper formation of gypsum crystals for efficient filtration, and minimizes the water load that must be removed during acid concentration.

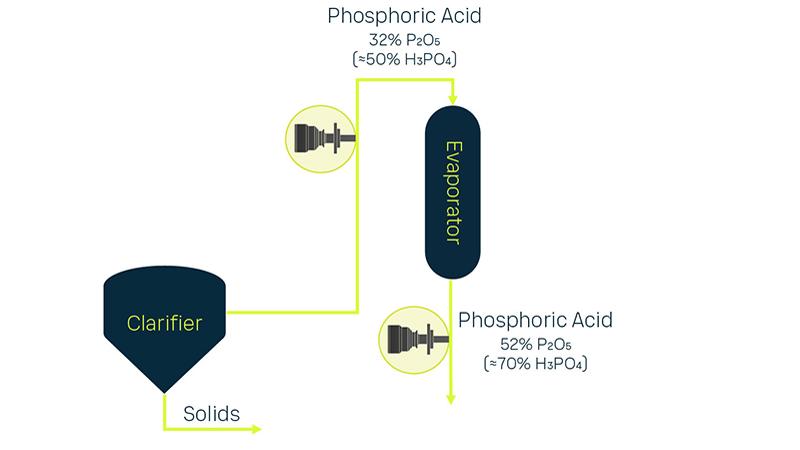

- Filtration

After the reaction, the resulting slurry contains around 30% solid material—primarily gypsum and unreacted rock. Filtration separates these solids from the phosphoric acid, yielding a 32% P₂O₅ (≈50% H₃PO₄) solution.

- Concentration

The phosphoric acid is then concentrated by evaporation to reach a commercial grade of around 54% P₂O₅ (≈70% H₃PO₄). In some cases, further purification may be applied to remove impurities, for example if the acid is intended for food-grade, pharmaceutical, or specialty industrial use.

Inline Refractometer Installation: Reactor Inlet/Outlet

The Vaisala Polaris™ PR53GP Process Refractometer enables in-line monitoring of acid concentrations throughout the wet process, eliminating the need for manual sampling and titration. There are two key locations for inlet refractometer installation:

- Measurement of sulfuric acid concentration at the reactor inlet:

Installed to monitor the sulfuric acid feed, refractometer ensures consistent concentration (93–98%), supporting efficient acidulation and minimizing evaporator energy consumption. It also helps manage the reactor's heat load and gypsum crystallization, both of which influence filtration performance and overall process yield.

- Measurement of Phosphoric acid at the reactor outlet:

Installed after the reactor, refractometer provides continuous monitoring of crude phosphoric acid concentration. This helps verify conversion efficiency, detect process upsets early, and maintain stable conditions for downstream filtration and evaporation. Since the measurement is unaffected by suspended gypsum or unreacted rock, it ensures reliable control even under challenging slurry conditions.

Inline Refractometer Installation: Clarifier & Evaporator Outlet

- Measurement of phosphoric acid after clarifier:

Refractometer monitors clarified acid concentration to ensure stable and optimal feed conditions for the evaporator. This supports efficient evaporation performance, prevents overload or underfeed situations and helps maintain steady product quality downstream.

- Monitoring of final phosphoric acid concentration at evaporator outlet:

Continuous monitoring of the final phosphoric acid concentration enables automated evaporator control. This ensures consistent product quality while optimizing steam consumption, resulting in improved energy efficiency and reduced operating costs

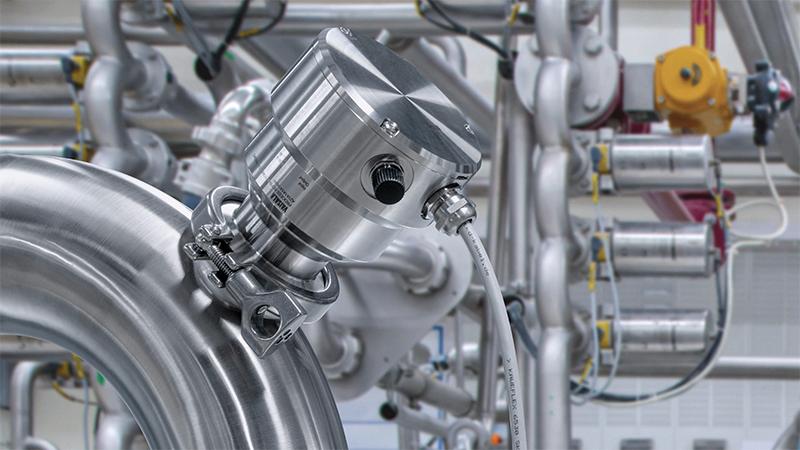

Solution – A Robust Inline Refractometer

Vaisala Polaris PR53GC and PR53GP refractometers are built for demanding industrial environments. The PR53GC is ideal for small pipelines and bypass lines, while the PR53GP offers flexible installation in a wide range of pipe sizes using standard flanges.

The refractometer measurement output can be configured in the preferred unit—% sulfuric acid, % phosphoric acid, % P₂O₅, or refractive index.

Features:

- Digital sensing and maintenance-free operation – High accuracy with long-term stability with no moving parts, no drift and no need for frequent recalibration.

- Real-time, continuous measurement – for immediate process control.

- Seamless integration – Installs easily via standard flanges or Type L clamp connections and supports analog and digital outputs (4–20 mA, HART, Modbus RTU, Modbus TCP/IP) for direct connection to DCS or PLC systems.

- Immune to bubbles and suspended solids – Provides stable readings by selectively measuring the liquid phase, even challenging, high abrasive and corrosive slurries.

- Certified for Hazardous Areas (EX certified) — Suitable for installation in explosive atmospheres.

Products and services

Polaris PR53GC Compact Process Refractometer

The PR53GC Compact Process Refractometer is suitable for a wide range of industrial applications. Special alloy materials are available for demanding environments. Convenient installation directly to pipeline with Type L coupling. A selection of flow cells available.

Polaris PR53GP Process Refractometer