Chlor-Alkali Process

Introduction

Sodium hydroxide or caustic soda is an inorganic compound with the formula NaOH. It is a white, translucent and hygroscopic solid, which forms a strong alkaline solution with water.

Sodium hydroxide is used as a caustic base and alkali in a wide range of industries.

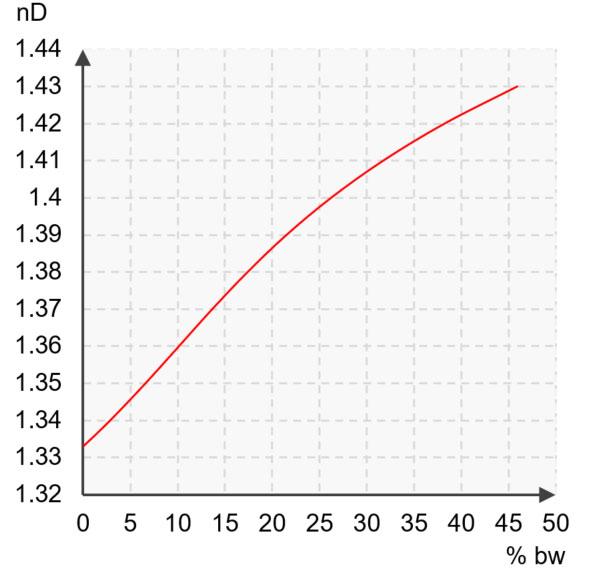

Chemical curve: Sodium hydroxide R.I. per Conc % b.w. at Ref. Temp. of 20˚C

Application

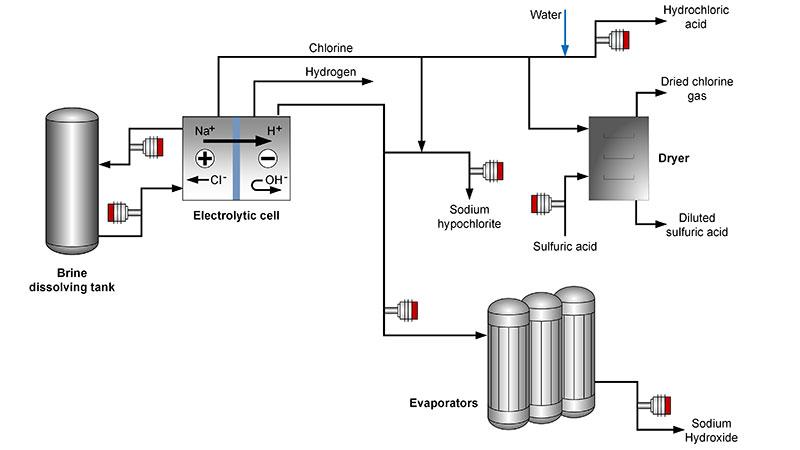

Sodium hydroxide is manufactured by electrolysis of sodium chloride solutions. Brine (NaCl in water) electrolysis produces chloride at the anode and hydrogen, along with the alkali hydroxide at the cathode.

Typically, sodium hydroxide is delivered in 30-40 % NaOH concentrations to customers, who will further dilute it for use at concentrations of 14-15 % NaOH.

These specific concentration percentages are obtained by mixing a full-strength solution with water.

Typical end products

Sodium Hydroxide (NaOH), Brine (NaCl), Hydrochloric Acid (HCl), Sodium Hypochlorite (NaClO):

- polymers

- resins

- elastomers

- PVC plastic

- in manufacturing of other chemicals, medicines, metallurgy, detergents and textiles.

Instrumentation and installation

Vaisala Polaris™ Process Refractometers are used to measure the concentration at different phases of the process. The first and the second measurements before the electrolytic cell, and in brine recirculation line, are NaCl measurements. Prior to the cell, the concentration varies between 250-320 g/l and the temperature between 50-70 ºC (122-158 ºF). In the recirculation line the numbers are 190-210 g/l and 70-90 ºC (158-194 ºF), respectively.

The third measurement is a hydrogen chloride (HCl) measurement. The concentration is 30-35 % and the temperature is ambient. A sulfuric acid concentration of 88-98 % is measured before feeding the product to the dryer at ambient temperature.

Sodium hydroxide measurements are taken prior to and after the evaporators. The pre-evaporator concentration is 25-35 % and after 45-55 %. The temperature decrease is from 70-90 ºC (158-194 ºF) to 30-50 ºC (86-122 ºF).

The last measurement is of NaClO, where the concentration is 0-12 % at ambient temperature.

The refractometer wetted parts are either plastic or metal alloys, depending on corrosion resistance requirements.

Several choices of refractometer wetted parts material are available for sodium chloride measurements, such as titanium or palladium doped titanium. For HCl the selection of material options includes tantalum, zirconium and chemically resistant Teflon body (PR53M) and Sounders body (PR53W) to ensure a viable service life.

It is the user’s responsibility to select the product wetted parts material, and to ensure that the material is satisfactory for the intended service conditions.

Vaisala Polaris Process Refractometers

The Vaisala Polaris PR53M PTFE-Body Process Refractometer is for chemically aggressive solutions and ultra-pure fine chemical processes. The PR53M can be mounted to ½ inch process lines with a standard NTP-threaded connection, or optional pillar or flare fittings.

Vaisala Polaris PR53W Process Refractometer (pictured) is designed to measure concentrations of aggressive chemicals. The PR53W is mounted in a membrane-lined valve body that has no metallic wetted parts. This allows convenient flange mounting to 2-inch ANSI, DN50, or JIS 50A flanges.

The Vaisala Polaris PR53GP Process Refractometer is a heavy-duty instrument with nonweld body construction for diverse applications. The PR53GP can be installed directly into a tank or large pipelines, using either a standard ANSI, DIN or JIS flange connection, or clamp connection.

User Interface

Vaisala Polaris process refractometers are compatible with the Indigo platform, offering plug-and-play connectivity, user-friendly interfaces and service and configuration tools. The Indigo520 transmitter adds a physical user interface, data logging, advanced diagnostics, automatic wash control, and access to measurement settings and parameters.

Measurement range

Refractive Index (nD) 1.3200 – 1.5300, corresponding to 0-100 % by weight.