Protect every cubic meter of your dry room with the new Vaisala DMP1

Stable, accurate dew point sensors are necessary to ensure that the entire internal environment of a dry room remains constantly within the required tolerances. This protects safety and ensures the manufacture of high-quality lithium-ion batteries.

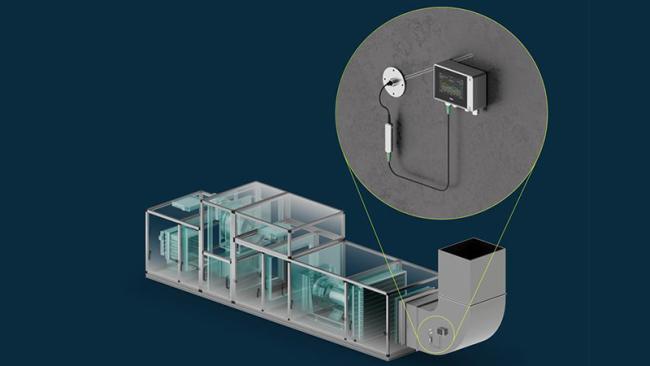

The new Vaisala DMP1 dew point sensor has been designed for this purpose, with the exacting requirements of battery production in mind. The Vaisala DMP1 is uniquely suited to battery production because it can be easily connected with a compatible Vaisala Indigo300 transmitter with a built-in display.

For maximum accuracy, multiple sensors should be installed at regular intervals. The goal is to ensure comprehensive coverage of each cubic meter of dry room. These sensors provide real-time data on moisture levels across the entire room, allowing for immediate adjustments to the drying units as needed.

What battery production needs from a dew point sensor

The most important feature of a dew point sensor is that it is able to take measurements quickly and accurately at the required level, usually around -50°C Td/f to -60°C Td/f in dry rooms. In fact, the Vaisala DMP1 can reliably measure down to -70°C Td/f if needed. But the best thing is that the sensor responds to dew point changes at that level in minutes instead of hours, which is the reaction speed typical of other measurement technologies. This means you can notice and fix any deviations in dew point in your dry rooms quickly and efficiently – ensuring product quality, maintaining safety, and reducing waste.

The reason the Vaisala DMP1 can react so quickly to dew point changes even at very low water molecule concentrations is the proven and reliable Vaisala DRYCAP® sensor. This technology is well-proven in a wide variety of industries. The sensor is built to tolerate challenging environments like battery production, with excellent resistance to chemicals and cleaning agents. For example, a sensor purge option heats the device to remove harmful chemicals and ensure accurate readings.

The Vaisala DMP1 is compatible with the Vaisala Indigo300 transmitter, which has a clear, easy-to-read display. This makes it easy for everyone on the production line to know what the dew point is at any time with just a glance – so that they can spot any deviations before they become a problem.

A complete sensor ecosystem

Vaisala offers a complete range of sensors to measure temperature, humidity, and CO2. All of these sensors are compatible with Indigo transmitters. The Indigo family's key feature is modularity. It includes a selection of transmitters and interchangeable smart probes that measure various parameters, covering all of the battery production measurement needs.

Another advantage is that maintenance is easier when all of your sensors are from a single provider – whether you’re sending in probes for calibration, having a technician on-site, or replacing the probes yourself. You can also be sure your system is future-proof as software updates apply to your whole sensor ecosystem, and upgraded sensors can be installed as they become available or needed.

Finally, there is the issue of trust. Avoiding safety issues and ensuring product quality requires reliable sensors that meet the needs of battery producers, and Vaisala has a long history of providing sensors for major producers in the battery industry. The Vaisala DMP1 is a replacement for the DMT341, which has seen extensive use in battery production.

Want to know how we can help measure key parameters in your battery production process?

Further reading

Accurate moisture and concentration measurements in battery manufacturing

Protect your dry room with fast-response, accurate monitor and control devices, and equip your dehumidifier unit and critical process steps—such as anode and cathode drying, solvents, glove boxes, and other inert atmospheres—with products engineered for the most demanding environments.

Contact us

Interested to receive more information on a specific application or product? Drop us a line, and we'll get back to you!